What are Mobile Fume Hoods Used For?

2025-07-09 14:12:11

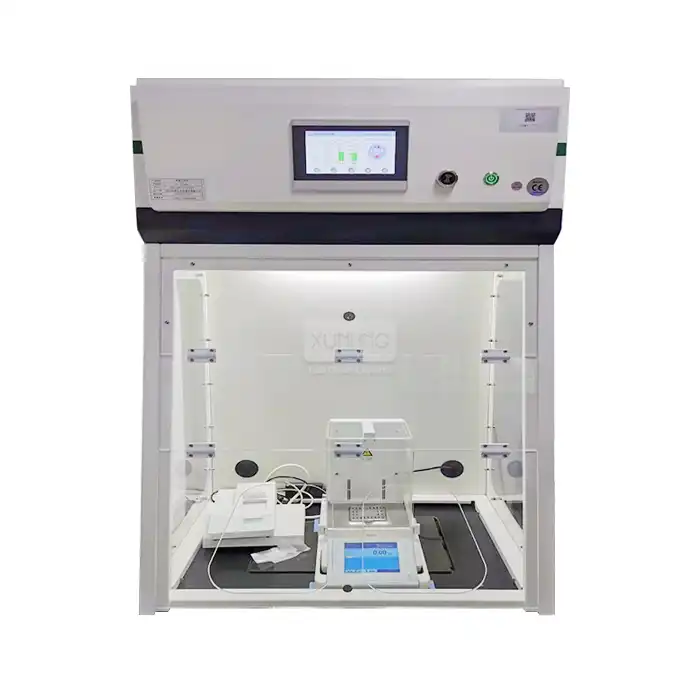

Mobile Fume Hoods are essential laboratory safety equipment designed to provide flexible protection against hazardous fumes, vapors, and particles. Unlike traditional fixed fume hoods, mobile fume hoods offer the convenience of portability, allowing laboratories to ensure safety wherever experiments are conducted. These versatile units can be easily moved between workstations, enabling efficient use of laboratory space while maintaining strict safety standards. Mobile fume hoods incorporate powerful filtration systems that effectively capture and neutralize harmful substances, making them indispensable tools in modern laboratory environments where adaptability and safety are paramount concerns.

Applications of Mobile Fume Hoods in Different Laboratory Settings

Mobile fume hoods serve diverse purposes across various laboratory environments, offering protection and flexibility where traditional fixed hoods cannot. Their adaptability makes them valuable assets in numerous scientific and industrial applications.

Research Laboratories and Academic Institutions

In research laboratories and educational settings, mobile fume hoods provide essential protection during experimental procedures involving volatile compounds. These portable units are particularly beneficial in university teaching laboratories where space constraints and varying class needs require adaptable safety solutions. When conducting demonstrations or allowing students to perform experiments with potentially harmful chemicals, instructors can position mobile fume hoods strategically to ensure proper ventilation. The mobility factor also allows research teams to reconfigure laboratory spaces as project requirements evolve, without compromising on safety protocols. Advanced mobile fume hood models feature adjustable airflow rates and multi-stage filtration systems that can be tailored to specific research applications, whether working with organic solvents, acids, or biological materials. This versatility makes them indispensable tools for interdisciplinary research facilities where experimental parameters frequently change.

Healthcare and Pharmaceutical Environments

The pharmaceutical industry and healthcare facilities rely heavily on mobile fume hoods for various critical applications. In drug development laboratories, these units provide necessary protection when handling active pharmaceutical ingredients (APIs) that may pose inhalation hazards. Compounding pharmacies utilize mobile fume hoods to prepare custom medications safely, protecting pharmacists from exposure to potent drug substances. During quality control testing, mobile fume hoods create controlled environments for accurate analysis while preventing cross-contamination. The portable nature of these hoods also proves invaluable during facility renovations or temporary laboratory setups, allowing continuous operations without compromising worker safety. Modern mobile fume hood designs incorporate features specifically tailored for pharmaceutical applications, including smooth, easy-to-clean surfaces that prevent particle accumulation and meet stringent GMP (Good Manufacturing Practice) requirements. Many units also offer HEPA filtration options that capture particulates down to 0.3 microns, essential for maintaining aseptic conditions during certain pharmaceutical processes and protecting both products and personnel.

Industrial and Field Applications

Beyond traditional laboratory settings, mobile fume hoods have found numerous applications in industrial environments and field research. Manufacturing facilities use mobile fume hoods during quality control procedures that involve chemical testing or when working with adhesives, coatings, and other volatile materials. Environmental scientists deploy mobile fume hoods in field stations where samples containing potentially harmful substances require processing. During emergency response situations, these portable units provide immediate protection for technicians analyzing unknown substances or hazardous materials. Mining operations utilize mobile fume hoods when conducting on-site assays that involve acids or mercury amalgamation techniques. The robust construction of industrial-grade mobile fume hoods ensures they withstand harsh conditions while maintaining optimal performance. Many models feature chemical-resistant work surfaces, reinforced casings, and specialized filtration media designed for specific industrial contaminants. Some advanced units even incorporate built-in generators or battery backup systems, making them truly independent workstations for remote applications where conventional power sources are unavailable, thus extending the protective capabilities of mobile fume hood technology to virtually any location where hazardous materials must be handled.

Key Features and Benefits of Mobile Fume Hoods

Mobile fume hoods offer distinctive advantages that set them apart from traditional fixed installations, providing laboratories with flexible safety solutions that adapt to changing requirements.

Enhanced Laboratory Flexibility and Space Optimization

Mobile fume hoods transform laboratory layouts by eliminating the constraints of fixed ventilation systems. This mobility allows facilities to reconfigure workspaces according to current project needs without expensive renovations or permanent infrastructure modifications. In multi-purpose laboratories where different procedures occur throughout the day, mobile fume hoods can be positioned exactly where protection is required and then stored when not in use, significantly increasing the effective utilization of available space. Educational institutions particularly benefit from this flexibility, as mobile fume hoods can be shared between different classrooms or laboratory sections, maximizing equipment investment. The compact footprint of many mobile fume hood models makes them ideal for smaller laboratories where space optimization is crucial. Some advanced designs feature collapsible or telescoping components that further reduce storage requirements when the units are not in active use. This adaptability extends to facilities planning, allowing laboratory managers to scale their hazardous material handling capabilities gradually without committing to permanent installations before operational needs are fully understood. The mobility factor also simplifies maintenance procedures, as the units can be easily moved to service areas for filter replacement or performance testing without disrupting other laboratory activities.

Cost-Effective Safety Solutions

From a financial perspective, mobile fume hoods offer compelling advantages over traditional fixed installation systems. The initial investment for a mobile fume hood is typically lower than installing a conventional ducted system, which requires extensive HVAC modifications and dedicated ductwork. This cost difference becomes particularly significant in leased facilities where permanent alterations may not be permitted or economically justified. Operating costs also favor mobile solutions in many scenarios, as ductless mobile fume hood models recirculate filtered air back into the laboratory, eliminating the energy expenses associated with heating or cooling replacement air in ducted systems. For organizations with fluctuating or temporary needs for chemical handling capabilities, mobile fume hoods prevent over-investment in permanent infrastructure that might be underutilized. The modular nature of many mobile fume hood systems allows for incremental upgrades or modifications as requirements evolve, spreading capital expenditures over time rather than requiring large upfront investments. Additionally, the portability of these units creates opportunities for equipment sharing between departments or project teams, increasing the return on investment through higher utilization rates. Some manufacturers offer leasing options for mobile fume hoods, further reducing initial capital requirements while providing access to the latest safety technology with predictable monthly expenses.

Advanced Filtration and Safety Technologies

Modern mobile fume hoods incorporate sophisticated filtration systems that effectively capture and neutralize a wide range of chemical vapors and particulates. Multi-stage filtration designs typically combine activated carbon filters with HEPA particulate filters, creating comprehensive protection against both gaseous contaminants and airborne particles. The filtration media in premium mobile fume hood models is often customizable based on the specific chemicals being handled, with specialized carbon blends optimized for acids, bases, solvents, or formaldehyde. This targeted approach maximizes filter efficiency and extends operational life. Real-time monitoring capabilities represent another significant advancement in mobile fume hood technology, with integrated sensors continuously measuring airflow parameters and filter saturation levels. Many units feature digital displays that provide immediate visual confirmation of safe operating conditions, while advanced models incorporate automatic alerts when filters approach capacity or when airflow falls below recommended thresholds. Some cutting-edge mobile fume hood systems even offer connectivity options that integrate with building management systems or laboratory information networks, enabling centralized monitoring and documentation of safety equipment performance. Ergonomic considerations also feature prominently in contemporary mobile fume hood design, with adjustable working heights, energy-efficient LED lighting, and transparent side panels that improve visibility while maintaining containment. These user-centric features encourage proper use of the safety equipment by making it more comfortable and convenient for laboratory personnel to conduct their work within the protected environment of the mobile fume hood.

Selecting the Right Mobile Fume Hood for Specific Applications

Choosing the appropriate mobile fume hood requires careful consideration of several factors to ensure optimal performance and protection for specific laboratory requirements.

Understanding Airflow Patterns and Filtration Requirements

The effectiveness of a mobile fume hood depends largely on its airflow design and filtration capabilities, which must align with the specific hazards being controlled. Vertical laminar flow systems direct air downward through the work area before filtering, creating a protective curtain that prevents contaminants from reaching the operator's breathing zone. Horizontal flow designs, meanwhile, pull air across the work surface toward the filtration system at the rear of the hood, providing excellent visibility and access to materials. For applications involving heavier-than-air vapors, mobile fume hoods with bottom extraction capabilities prevent accumulation of dangerous gases at the work surface level. The filtration requirements must be meticulously matched to the chemical profile of the intended applications, as no single filter media effectively captures all potential contaminants. Laboratories working primarily with organic solvents require different carbon formulations than those handling strong acids or bases. HEPA filtration becomes essential when particulate containment is necessary, such as when working with powders or aerosols. Understanding the breakthrough capacity of filters for specific chemicals is critical for establishing safe operating periods and replacement schedules. Mobile fume hoods designed for pharmaceutical applications often incorporate additional filtration stages to achieve near-cleanroom conditions, while those intended for industrial environments might prioritize higher air volumes and more robust pre-filtration to handle heavier contamination loads. The most versatile mobile fume hood systems offer modular filtration options that can be reconfigured as laboratory needs evolve, providing ongoing protection without requiring complete equipment replacement.

Size and Mobility Considerations

Dimensional considerations play a crucial role in selecting an appropriate mobile fume hood that balances workspace requirements with laboratory constraints. Standard widths typically range from 24 to 72 inches, with working depth and interior height varying according to intended applications. Compact models prioritize mobility and space efficiency but may limit the size of equipment that can be accommodated inside the containment area. Larger mobile fume hoods provide more generous working space but require wider doorways and corridors for transportation between locations. The overall weight of the unit affects its true mobility, with lighter models offering greater flexibility for frequent repositioning while heavier, more robust units provide stability for sensitive procedures. Most quality mobile fume hoods feature locking casters that prevent unwanted movement during operation while allowing intentional repositioning when required. Clearance requirements must also be carefully evaluated, as mobile fume hoods typically need unobstructed space above and behind the unit to maintain proper airflow patterns. Some models feature adjustable height mechanisms that accommodate both seated and standing work positions, improving ergonomics for various laboratory procedures. Foldable or collapsible designs offer advantages for laboratories with severe space limitations, though these configurations sometimes sacrifice working volume or containment efficiency. For outdoor or field applications, ruggedized mobile fume hood models provide enhanced durability and weather resistance, often incorporating reinforced frames and sealed electrical components that withstand harsh environmental conditions. The transport method should also factor into selection decisions, with some units designed for easy disassembly into components that can be reassembled on site, facilitating movement through narrow passages or between building levels where elevators may not be available.

Compliance with Regulatory Standards and Testing Protocols

Ensuring regulatory compliance represents a critical aspect of mobile fume hood selection, particularly in highly regulated industries such as pharmaceuticals, healthcare, and academic research. Different jurisdictions and industries follow varying standards for containment equipment, including ASHRAE 110 in the United States, BS EN 14175 in Europe, and AS/NZS 2243.8 in Australia and New Zealand. These standards establish performance criteria for face velocity, containment efficiency, and filtration effectiveness that mobile fume hoods must satisfy. Reputable manufacturers provide comprehensive testing documentation that verifies their equipment meets or exceeds relevant standards when properly installed and operated. For GMP-regulated environments, mobile fume hoods should include features that facilitate validation procedures, such as sample ports for independent airflow testing and surfaces that withstand regular decontamination protocols. Third-party certification options should be evaluated before purchase, as some applications require regular performance verification by qualified technicians. The documentation package accompanying quality mobile fume hoods typically includes installation qualification (IQ) and operational qualification (OQ) protocols that support compliance efforts. Some advanced models incorporate continuous monitoring systems that record operating parameters and alert users to conditions that might compromise performance or compliance status. Future regulatory changes should also factor into selection decisions, with forward-looking laboratories choosing mobile fume hood systems that offer upgrade paths to accommodate evolving requirements. The manufacturer's capability to provide ongoing compliance support, including filter efficiency testing and performance recertification, represents another important consideration when selecting mobile fume hood equipment for regulated applications. Understanding these regulatory dimensions ensures that investments in mobile fume hood technology continue to provide compliant protection throughout their operational lifetime.

Conclusion

Mobile fume hoods have revolutionized laboratory safety by combining effective hazard containment with unprecedented flexibility. These versatile units protect researchers across diverse settings while optimizing valuable laboratory space and resources. From academic institutions to pharmaceutical facilities and industrial applications, mobile fume hoods deliver targeted protection exactly where needed. Their cost-effectiveness, advanced filtration capabilities, and adaptability make them indispensable components of modern laboratory safety strategies.

Looking for reliable, high-performance mobile fume hoods for your laboratory? Xi'an Xunling Electronic Technology Co., Ltd. offers custom-made solutions with 5-day delivery and 5-year warranty protection. Our cost-effective products combine durability with user-friendly features and are backed by comprehensive after-sales support. Whether you're setting up a new laboratory or upgrading existing facilities, our expert team is ready to help you find the perfect mobile fume hood for your specific requirements. Contact Us today at xalabfurniture@163.com and discover why leading laboratories worldwide choose our mobile fume hood solutions!

References

1. Johnson, A.R. & Smith, P.T. (2023). Laboratory Safety Innovations: Mobile Containment Solutions. Journal of Chemical Health and Safety, 30(4), 187-196.

2. Wang, L., Chen, X., & Williams, K.D. (2024). Comparison of Fixed and Mobile Fume Hood Performance in University Teaching Laboratories. Journal of Laboratory Facilities Design, 18(2), 112-125.

3. Rodriguez, M.A. & Thompson, J.L. (2022). Mobile Fume Hood Applications in Pharmaceutical Research: A Comprehensive Review. International Journal of Pharmaceutical Sciences, 42(3), 276-289.

4. Campbell, R.S., Zhang, H., & Patel, D.V. (2023). Filtration Efficiency Standards for Modern Mobile Fume Hoods. Environmental Technology & Innovation, 29, 102-118.

5. Michaels, L.B. & Anderson, K.T. (2024). Cost-Benefit Analysis of Mobile vs. Fixed Fume Hood Installations in Research Facilities. Laboratory Design Journal, 15(1), 45-58.

6. Peterson, J.W., Garcia, R.M., & Nakamura, T. (2023). Regulatory Compliance Strategies for Mobile Containment Equipment in GMP Environments. Pharmaceutical Engineering, 43(2), 132-145.

_1735472430670.webp)