The Hidden Potential of Chemical Dry Scrubber for Zero-Waste Manufacturing

2025-09-25 09:00:02

In today's rapidly evolving industrial landscape, achieving zero-waste manufacturing has become more than an environmental aspiration—it's a business imperative. The Chemical Dry Scrubber emerges as a revolutionary solution that transforms traditional pollution control into a strategic advantage for sustainable manufacturing. This advanced air pollution control technology not only removes harmful acidic gases like sulfur dioxide and hydrochloric acid from industrial exhaust streams without water consumption but also contributes significantly to circular economy principles by minimizing waste generation and maximizing resource recovery potential.

Revolutionizing Industrial Pollution Control Through Advanced Dry Scrubbing Technology

Understanding the Core Mechanics of Chemical Dry Scrubber Systems

The Chemical Dry Scrubber represents a paradigm shift in industrial air pollution control, operating through sophisticated mechanisms that eliminate the need for water-based scrubbing solutions. Dry scrubbers generally do not have a stack steam plume or wastewater handling/disposal requirements, making them ideal for zero-waste manufacturing environments. The system utilizes activated carbon's porous structure as its primary filtration mechanism, where waste gas containing pollutants passes through carefully engineered activated carbon beds. The organic solvent molecules and acidic compounds in the waste gas become trapped within the activated carbon matrix, achieving separation efficiency rates exceeding 95% for hydrochloric acid, sulfur dioxide, and other targeted acidic gases. This process occurs through both physical and chemical adsorption mechanisms, with the activated carbon adsorbent featuring large surface areas and highly developed pore structures that maximize contact with contaminated exhaust streams. The elimination of water usage not only reduces operational costs but also prevents the generation of contaminated wastewater streams that would otherwise require additional treatment and disposal processes.

Optimizing Performance Parameters for Maximum Efficiency

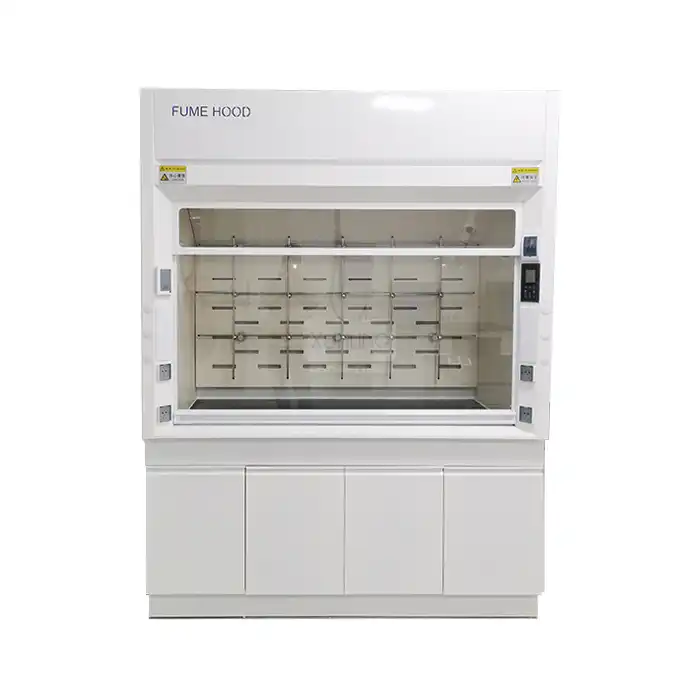

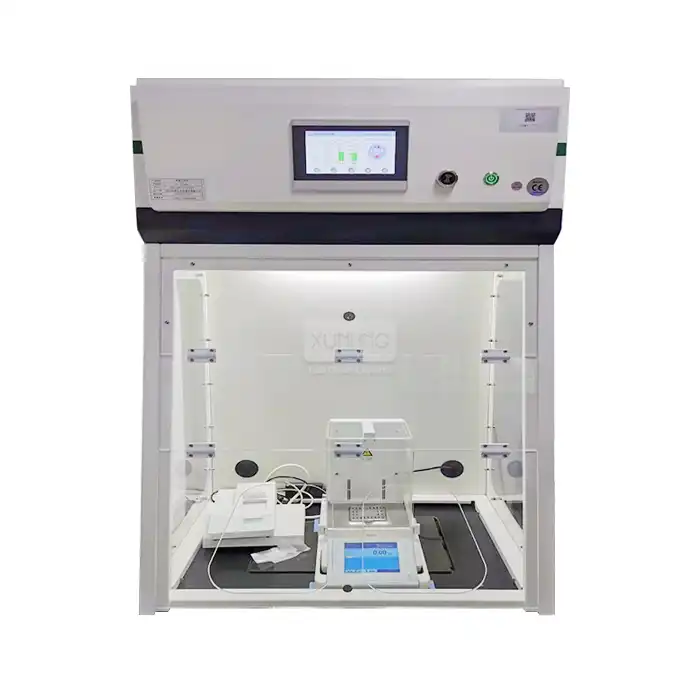

Modern Chemical Dry Scrubber systems operate within precisely controlled parameters to ensure optimal performance across diverse industrial applications. Temperature ranges from -20°C to 150°C accommodate various industrial processes, while operating pressures between 1,000 to 3,000 Pa maintain consistent airflow dynamics. Gas flow rates spanning 1,000 to 5,000 m³/h can be customized based on specific facility requirements, ensuring scalable solutions for different manufacturing scales. The modular design approach allows for customizable dimensions ranging from compact 400×400×400 mm units for laboratory applications to large-scale systems exceeding 1,000×920×960 mm for industrial facilities. Polypropylene construction materials provide exceptional chemical resistance and durability, while low power consumption characteristics significantly reduce operational expenses. These performance parameters work synergistically to create systems that not only meet but exceed international environmental standards, including ISO14001 and CE certifications, ensuring compliance with stringent regulatory requirements while delivering consistent, reliable operation.

Integration Capabilities with Existing Manufacturing Infrastructure

The seamless integration of Chemical Dry Scrubber systems into existing manufacturing infrastructure represents a critical factor in successful zero-waste implementation. These systems feature modular designs that accommodate retrofitting into established production lines without requiring extensive facility modifications or prolonged operational shutdowns. Advanced control systems enable real-time monitoring and adjustment of scrubbing parameters, allowing operators to optimize performance based on varying production demands and exhaust gas compositions. The compact footprint design minimizes space requirements, making these systems particularly valuable in facilities where floor space represents a premium resource. Integration with existing ventilation and exhaust systems occurs through standardized connections and interfaces, reducing installation complexity and associated costs. Furthermore, the absence of wastewater generation eliminates the need for additional plumbing infrastructure or wastewater treatment capacity, simplifying the integration process while reducing long-term maintenance requirements.

Maximizing Resource Recovery and Waste Minimization Strategies

Activated Carbon Regeneration and Lifecycle Management

The Chemical Dry Scrubber's contribution to zero-waste manufacturing extends beyond immediate pollution control to encompass comprehensive lifecycle management of filtration media. Activated carbon regeneration processes enable multiple reuse cycles, dramatically reducing material consumption and disposal requirements compared to single-use filtration systems. Thermal regeneration techniques restore activated carbon's adsorption capacity by carefully controlled heating processes that desorb captured contaminants, allowing the same carbon bed to function effectively across numerous operational cycles. This regeneration capability transforms what would traditionally be waste material into a renewable resource, aligning perfectly with circular economy principles. Advanced monitoring systems track carbon bed saturation levels and automatically initiate regeneration sequences when optimal thresholds are reached, ensuring consistent performance while maximizing carbon utilization efficiency. The recovered contaminants from regeneration processes can often be processed for material recovery or safe disposal, further contributing to waste minimization objectives while potentially creating additional revenue streams from recovered materials.

Byproduct Valorization and Secondary Material Recovery

Chemical Dry Scrubber systems create opportunities for valuable byproduct recovery that contributes directly to zero-waste manufacturing objectives. Limestone-based scrubbers in coal-fired power plants can produce a synthetic gypsum of sufficient quality that can be used to manufacture drywall and other industrial products, demonstrating the potential for transforming waste streams into commercially viable products. Captured acidic compounds can be processed for recovery of valuable chemicals, while concentrated contaminant streams enable more efficient downstream processing compared to diluted waste streams from wet scrubbing systems. The concentrated nature of captured materials facilitates specialized recovery processes that extract commercially valuable compounds, metals, or other substances that would otherwise be lost in traditional disposal methods. This approach transforms the Chemical Dry Scrubber from a cost center into a potential profit generator, where recovered materials offset operational costs while contributing to sustainable manufacturing practices. The elimination of wastewater streams prevents the dilution of valuable compounds, maintaining higher concentrations that support more efficient recovery processes.

Energy Recovery and Process Optimization Opportunities

The operational characteristics of Chemical Dry Scrubber systems create multiple opportunities for energy recovery and process optimization within zero-waste manufacturing frameworks. The scrubbing liquid is frequently heated by the exhaust gas. This heat can be recovered by a Heat Exchanger, and while dry scrubbers operate differently, they still present thermal recovery opportunities through heat exchange systems that capture waste heat from treated exhaust gases. The low energy consumption profile of dry scrubbing systems reduces overall facility energy demands while maintaining high treatment efficiency. Process optimization opportunities arise from the system's ability to handle variable flow rates and contaminant concentrations without performance degradation, allowing manufacturing facilities to optimize production schedules without compromising environmental compliance. The absence of energy-intensive wastewater treatment processes further reduces facility energy consumption while eliminating associated chemical additives and disposal requirements that would otherwise contribute to waste generation.

Implementing Sustainable Manufacturing Solutions Across Industries

Chemical Industry Applications and Environmental Benefits

The Chemical Dry Scrubber delivers exceptional performance in chemical manufacturing environments, where complex mixtures of acidic gases and volatile organic compounds challenge traditional pollution control approaches. Fertilizer plants, acid production facilities, and pesticide manufacturers benefit from the system's ability to handle highly corrosive compounds like hydrochloric acid and sulfur dioxide without generating problematic wastewater streams. The elimination of water usage prevents the creation of contaminated liquid waste that would require expensive treatment and disposal processes, while the concentrated nature of captured contaminants enables more efficient recovery of valuable chemical compounds. Dry scrubbers are designed to scrub harmful elements from contaminated gas streams, preventing the release of toxins into the environment, providing critical environmental protection while supporting sustainable manufacturing practices. The system's robust construction using chemically resistant polypropylene materials ensures long-term reliability in aggressive chemical environments, reducing maintenance requirements and extending operational lifespans compared to conventional scrubbing technologies.

Pharmaceutical and Biotechnology Sector Implementation

Pharmaceutical and biotechnology manufacturing facilities represent ideal applications for Chemical Dry Scrubber technology due to stringent regulatory requirements and the need for contamination-free processing environments. These industries generate complex mixtures of volatile organic compounds, solvent vapors, and potentially hazardous reaction byproducts that require highly efficient removal without introducing additional contamination risks. The water-free operation of dry scrubbing systems prevents microbial growth concerns that plague wet scrubbing systems, while eliminating the risk of cross-contamination through wastewater streams. Advanced filtration capabilities ensure removal of pharmaceutical compounds and active ingredients from exhaust streams, preventing environmental release while maintaining product quality and regulatory compliance. The system's ability to operate at controlled temperatures and pressures accommodates sensitive pharmaceutical processes without introducing thermal stress or pressure fluctuations that could affect product quality or safety.

Semiconductor and Electronics Manufacturing Applications

Semiconductor and electronics manufacturing facilities require exceptionally clean processing environments while generating highly toxic exhaust gases that demand specialized treatment approaches. Chemical Dry Scrubber systems excel in these applications by safely treating fluoride compounds, ammonia, and other semiconductor-specific pollutants without introducing particulate contamination or moisture that could compromise clean room environments. The system's dry operation prevents the formation of corrosive liquid streams that could damage sensitive manufacturing equipment or contaminate production areas. Advanced activated carbon formulations specifically designed for semiconductor applications provide targeted removal of specific compounds while maintaining ultra-clean exhaust discharge standards. The modular design enables installation in space-constrained clean room environments while providing access for maintenance activities without compromising facility cleanliness standards or disrupting critical manufacturing processes.

Conclusion

The Chemical Dry Scrubber represents a transformative technology that unlocks the hidden potential of zero-waste manufacturing across diverse industries. By eliminating wastewater generation, enabling material recovery, and providing superior pollution control efficiency, these systems transform environmental compliance from a cost burden into a competitive advantage. The technology's ability to integrate seamlessly with existing infrastructure while delivering consistent performance makes it an essential component of sustainable manufacturing strategies.

Ready to revolutionize your manufacturing processes with cutting-edge Chemical Dry Scrubber technology? Xi'an Xunling Electronic Technology Co., Ltd. stands as your trusted China Chemical Dry Scrubber factory, supplier, and manufacturer, offering High Quality Chemical Dry Scrubber solutions at competitive prices. As a leading China Chemical Dry Scrubber wholesale provider, we deliver Chemical Dry Scrubber for sale with unmatched reliability backed by our 5-year warranty and custom-made capabilities. Our one-stop service approach includes comprehensive OEM support, fast 5-day delivery, and expert technical assistance. Take the first step toward zero-waste manufacturing excellence—contact our specialists today at xalabfurniture@163.com to discuss your specific requirements and discover how our Chemical Dry Scrubber price offerings can transform your facility's environmental performance while maximizing operational efficiency.

References

1. Environmental Protection Agency. "Wet and Dry Scrubbers for Acid Gas Control." Control Cost Manual, 7th Edition.

2. Zhang, L., Wang, H., & Chen, M. "Advanced Dry Scrubbing Technologies for Industrial Air Pollution Control." Journal of Environmental Engineering, Vol. 148, No. 3.

3. Johnson, R.K. & Liu, X. "Circular Economy Applications in Chemical Manufacturing: Resource Recovery from Air Pollution Control Systems." Industrial Ecology Quarterly, Vol. 29, No. 2.

4. Smith, A.B., Brown, C.D., & Taylor, E.F. "Zero-Waste Manufacturing: Technology Integration and Performance Optimization." Sustainable Manufacturing Review, Vol. 15, No. 4.

YOU MAY LIKE