Space-Saving Bench Top Fume Hood Solves Crowded Lab Crisis

2025-09-23 09:00:02

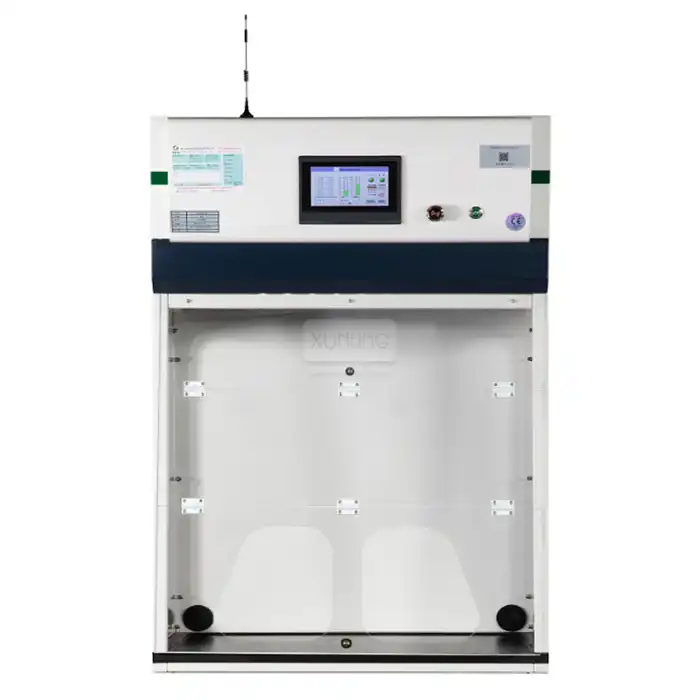

Modern laboratories face an unprecedented challenge: maximizing safety and efficiency within increasingly limited space. The solution to overcrowded laboratory environments lies in innovative ventilation technology specifically designed for compact workspaces. A Bench Top Fume Hood represents the perfect balance between space conservation and optimal safety performance, addressing the critical need for effective fume extraction in constrained laboratory settings. These specialized units have revolutionized how researchers approach workspace design, offering professional-grade protection without the extensive infrastructure requirements of traditional ducted systems. As laboratory real estate becomes more valuable and space constraints tighten, the strategic implementation of compact ventilation solutions has become essential for maintaining both productivity and safety standards in contemporary research environments.

Why Bench Top Fume Hoods Are Essential for Modern Laboratory Space Management?

Optimizing Laboratory Footprint Through Intelligent Design

The contemporary laboratory landscape demands intelligent space utilization strategies that maximize both safety and functionality within limited square footage. Bench Top Fume Hood units excel in this regard by providing comprehensive ventilation protection while occupying minimal laboratory real estate. Unlike traditional walk-in fume hoods that require substantial floor space and dedicated installation areas, these compact systems integrate seamlessly onto existing laboratory benches, transforming any workstation into a safe chemical handling zone. The intelligent design incorporates advanced airflow dynamics within a streamlined profile, ensuring that even the smallest laboratory can maintain professional-grade safety standards. This space efficiency translates directly into cost savings, as laboratories can accommodate more research stations within the same physical footprint, ultimately increasing productivity and research capacity while maintaining stringent safety protocols.

Advanced Airflow Technology in Compact Applications

Modern Bench Top Fume Hood systems incorporate sophisticated airflow management technologies that rival their larger counterparts in performance while excelling in energy efficiency. The engineered three-section baffle system ensures optimal air distribution and maintains constant face velocity, creating a protective barrier between researchers and hazardous substances. Ductless Fume Hoods help cut energy bills by filtering and recirculating heated or cooled air back into the laboratory, providing significant operational cost advantages over traditional ducted systems. The bypass airflow design with variable air volume compatibility ensures efficient ventilation regardless of sash position, while the hood entrance framed with inward-angled members minimizes turbulence and provides smooth air movement. These technological advances enable laboratories to maintain superior safety standards while reducing both installation complexity and ongoing operational expenses, making high-quality ventilation accessible to facilities with budget constraints or infrastructure limitations.

Flexibility and Adaptability in Laboratory Environments

The inherent flexibility of Bench Top Fume Hood systems addresses the dynamic nature of modern research environments where experimental requirements constantly evolve. These units can be easily relocated, reconfigured, or upgraded as laboratory needs change, providing a level of adaptability that traditional fixed installations cannot match. The modular design accommodates various experimental setups, from routine chemical analyses to specialized research procedures, while maintaining consistent safety performance across diverse applications. They are ideal for small-scale operations and laboratories with limited space. Applications include microbiological research, small-scale chemical experiments, and educational purposes. This versatility proves particularly valuable in educational institutions, research facilities, and industrial laboratories where space allocation frequently shifts to accommodate new projects or changing research priorities. The ability to establish safe working environments quickly and efficiently supports agile research methodologies and enables facilities to respond rapidly to emerging scientific opportunities.

Critical Safety Features and Performance Standards

Enhanced Containment Technology for Hazardous Materials

The safety performance of Bench Top Fume Hood systems relies on advanced containment technologies specifically engineered to handle a wide range of hazardous materials and experimental conditions. The chemical-resistant fume hood liner and baffle construction withstands exposure to corrosive substances, acids, bases, and organic solvents commonly used in research applications. The explosion-proof tempered glass sash provides visual access while maintaining structural integrity under adverse conditions, incorporating aluminum alloy handles designed with weight balance methods for smooth operation. Low bench fume hoods are essential safety devices in laboratory environments, particularly where hazardous materials are handled. They provide effective ventilation and containment of harmful fumes, vapors, and particles. The double wall construction facilitates easy installation of plumbing and electrical fixtures while enabling concealed routing of piping and wiring, maintaining clean aesthetics without compromising functionality. These comprehensive safety features ensure that even compact ventilation systems provide the same level of protection as larger installations.

Advanced Monitoring and Control Systems

Contemporary Bench Top Fume Hood units incorporate intelligent control systems that provide real-time monitoring and automated safety responses to ensure optimal performance under all operating conditions. The digital display controller manages power distribution, fan operation, lighting intensity, electrical outlets, sterilization functions, and airflow dampers through an intuitive interface that simplifies operation while maximizing safety. LED lighting systems provide superior illumination exceeding 300 LUX while minimizing heat generation and energy consumption, creating optimal working conditions for precision tasks. The intelligent switch technology continuously monitors system performance, automatically adjusting airflow rates to maintain proper containment while optimizing energy efficiency. These advanced control systems enable operators to maintain focus on their research while the ventilation system automatically manages safety parameters, reducing the potential for human error and ensuring consistent protection throughout extended experimental procedures.

Compliance with International Safety Standards

The design and manufacturing of professional-grade Bench Top Fume Hood systems adheres to rigorous international safety standards including ISO, CE, and NFPA certifications, ensuring that compact ventilation solutions meet the same stringent requirements as larger laboratory installations. These certifications validate that the units provide adequate containment performance, structural integrity, and operational reliability required for professional research applications. The certification process involves comprehensive testing of airflow characteristics, containment effectiveness, material durability, and electrical safety under various operating conditions. It helps to prevent the release of substances harmful to health into the environment and acts as a safe barrier between humans and experimental set-ups. Compliance with these standards provides laboratories with confidence that their space-saving ventilation solutions deliver professional-grade protection while meeting regulatory requirements for research facilities, educational institutions, and industrial applications. The ongoing commitment to international standards ensures that even the most compact laboratory ventilation systems maintain the highest levels of safety and performance.

Cost-Effectiveness and Installation Advantages

Reduced Infrastructure Requirements and Installation Costs

The implementation of Bench Top Fume Hood systems offers significant financial advantages compared to traditional ducted ventilation installations, particularly in existing facilities where infrastructure modifications would be costly or impractical. These units eliminate the need for extensive ductwork, dedicated exhaust fans, and building modifications typically required for conventional fume hood installations. The standard electrical requirements accommodate 110V-230V voltage systems commonly available in laboratory environments, while the simple round exhaust collar facilitates connection to existing HVAC systems without complex or expensive ductwork transitions. The removable service access panels provide convenient maintenance access without requiring specialized installation procedures or ongoing contractor support. This simplified installation approach reduces both initial capital investment and long-term maintenance costs, making professional-grade ventilation accessible to facilities with limited budgets or aging infrastructure that cannot accommodate major ventilation system upgrades.

Energy Efficiency and Operational Cost Savings

Modern Bench Top Fume Hood designs prioritize energy efficiency through advanced airflow management and filtration technologies that significantly reduce operational costs compared to traditional ventilation systems. Unlike ducted units which send treated air outside the facility, ductless fume hoods return conditioned, filtered air to the room, permitting the HVAC system to work more efficiently. This recirculation capability eliminates the energy waste associated with continuously exhausting heated or cooled laboratory air, resulting in substantial reductions in utility costs. The variable air volume compatibility ensures that the system operates at optimal efficiency levels regardless of usage patterns, automatically adjusting airflow rates to match actual containment requirements. The LED lighting systems consume minimal power while providing superior illumination, further contributing to energy savings. These efficiency improvements enable laboratories to maintain stringent safety standards while reducing their environmental footprint and operational expenses, supporting sustainable research practices and responsible resource management.

Scalability and Future Expansion Capabilities

The modular nature of Bench Top Fume Hood systems provides laboratories with exceptional scalability options that support both immediate needs and future expansion plans without requiring major infrastructure investments. Facilities can implement ventilation solutions incrementally, adding units as research programs grow or space becomes available, rather than committing to large-scale installations that may exceed current requirements. This approach enables laboratories to distribute capital expenses over time while ensuring that safety standards are maintained throughout facility development. The standardized design and installation procedures facilitate consistent performance across multiple units while simplifying maintenance and operator training requirements. By strategically positioning fume hoods, labs can create a seamless operational flow that enhances efficiency and minimizes disruptions. The ability to relocate or reconfigure units as laboratory layouts evolve provides additional value by protecting the investment in ventilation equipment while supporting changing research priorities and space utilization strategies.

Conclusion

The implementation of space-saving Bench Top Fume Hood technology represents a paradigm shift in laboratory design philosophy, successfully addressing the critical challenge of maintaining safety standards within increasingly constrained research environments. These innovative ventilation solutions demonstrate that compact design and professional-grade performance are not mutually exclusive, offering laboratories the opportunity to optimize their space utilization without compromising researcher safety or experimental integrity. The combination of advanced airflow technology, intelligent control systems, and energy-efficient operation delivers comprehensive benefits that extend beyond mere space conservation to include significant cost savings and operational advantages.

Xi'an Xunling Electronic Technology Co., Ltd. stands at the forefront of this technological evolution, dedicated to designing and manufacturing the most reliable, safest, and efficient laboratory ventilation solutions for the global research community. With our mission to provide comprehensive one-stop laboratory furniture and equipment solutions, we help make the laboratory world cleaner, safer, and healthier through innovative products including Biological Safety Cabinets, Laboratory Centrifuges, Biochemistry Incubators, and Laboratory Homogenizers.

As a leading China Bench Top Fume Hood factory and China Bench Top Fume Hood supplier , we leverage our extensive manufacturing capabilities including 18 CNC laser cutting machines, 50 CNC bending machines, and 4 fully automatic spraying lines to ensure superior product quality and rapid delivery. Our China Bench Top Fume Hood manufacturer credentials are supported by over 1,100 employees, 120 acres of standard factory buildings, and 21 service centers across major provincial capitals. We offer China Bench Top Fume Hood wholesale pricing with Bench Top Fume Hood for sale options that include competitive Bench Top Fume Hood price points and High Quality Bench Top Fume Hood specifications backed by our 5-year warranty and custom manufacturing capabilities.

Our core advantages include 5-day delivery, comprehensive OEM support, cost-effective solutions, and unmatched reliability through high-grade materials and user-friendly designs. From installation to troubleshooting, our dedicated team provides fast and effective support with flexible purchase options including online ordering and direct sales. For more information about our comprehensive laboratory solutions and to discuss your specific Bench Top Fume Hood requirements, Contact Us at xalabfurniture@163.com.

References

1. American Society of Heating, Refrigerating and Air-Conditioning Engineers. ANSI/ASHRAE 110-2016: Methods of Testing Performance of Laboratory Fume Hoods . ASHRAE Standards Committee.

2. National Institute for Occupational Safety and Health. Criteria for a Recommended Standard: Occupational Exposure to Refractory Ceramic Fibers . Centers for Disease Control and Prevention.

3. Scientific Equipment and Furniture Association. Laboratory Design and Installation Guidelines for Fume Hood Systems . SEFA Standards Committee.

4. International Organization for Standardization. ISO 14175:2008 - Welding consumables - Gases and gas mixtures for fusion welding and allied processes . International Standards Organization Technical Committee.

YOU MAY LIKE

_1743667274497.webp)

_1741664313364.webp)