Self Contained Fume Hood FAQ: Everything Laboratory Managers Need

2025-10-01 09:00:02

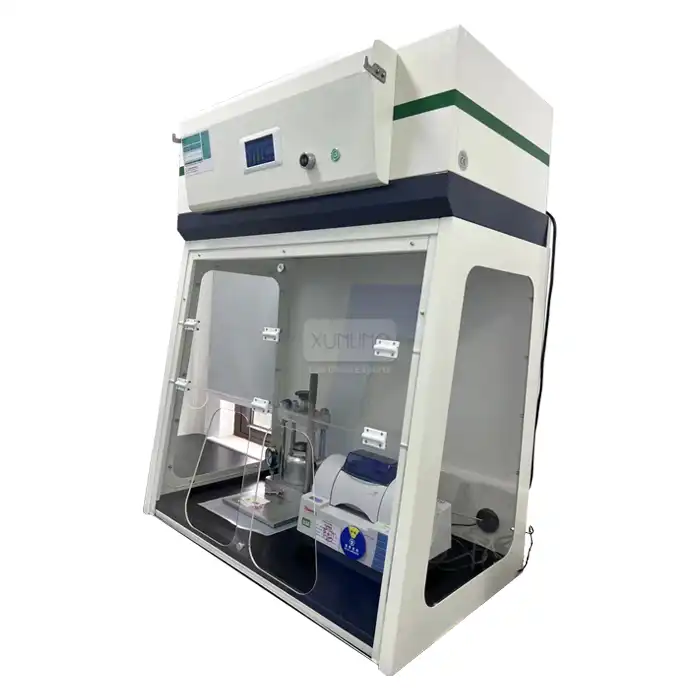

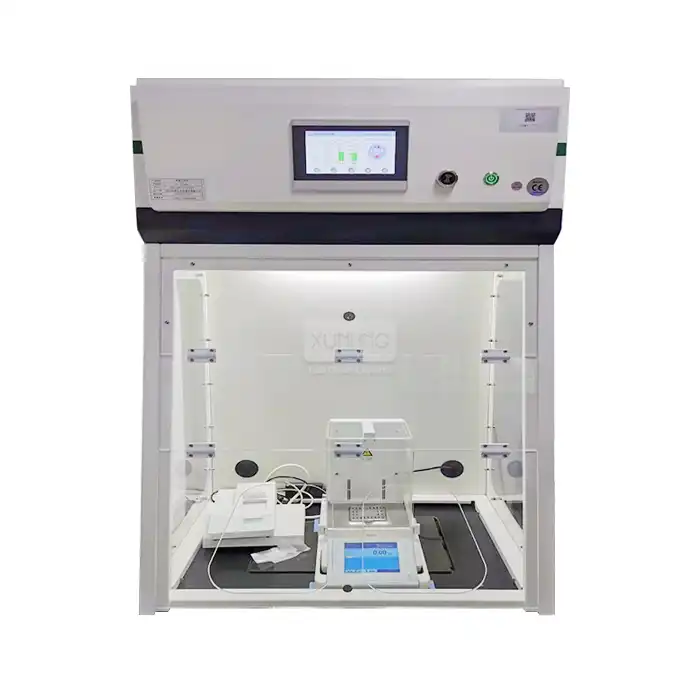

Laboratory managers constantly face the challenge of maintaining safe working environments while optimizing operational efficiency and cost-effectiveness. Self Contained Fume Hood technology emerges as a revolutionary solution that addresses these critical concerns through integrated filtration systems that require no external ductwork. These innovative devices capture, filter, and recirculate air within the laboratory space, providing comprehensive protection against hazardous chemical vapors, fumes, and particulate matter while eliminating the need for complex installation procedures. The Self Contained Fume Hood represents a paradigm shift in laboratory safety equipment, offering unprecedented flexibility and operational advantages over traditional ducted systems. Understanding the key features, installation requirements, safety protocols, and maintenance procedures is essential for laboratory managers seeking to create optimal working environments. This comprehensive guide addresses the most frequently asked questions about Self Contained Fume Hood technology, providing valuable insights to help laboratory managers make informed decisions that enhance both safety and productivity in their facilities.

What Are the Key Features and Benefits of Self Contained Fume Hoods?

Advanced Filtration Technology and Safety Systems

Self Contained Fume Hood systems incorporate sophisticated multi-stage filtration technology that ensures maximum protection against a wide range of hazardous substances commonly encountered in laboratory environments. The filtration system typically consists of pre-filters that capture larger particulate matter, followed by HEPA filters that remove fine particles with 99.97% efficiency at 0.3 microns, and activated carbon filters that absorb chemical vapors and organic compounds. Laboratory Fume Hoods are the first defense to minimize chemical exposure to research workers and are considered the primary means of protection from inhalation of hazardous vapors because they capture, contain, and expel emissions generated by hazardous chemicals. The Xi'an Xunling Self Contained Fume Hood models feature real-time monitoring systems with LCD displays that continuously track airflow velocity, filter saturation levels, and system performance parameters. These advanced safety features include alarm systems that alert users to potential issues, ensuring consistent protection throughout operation. The adjustable airflow velocity ranging from 0.3 to 0.7 m/s allows for optimal containment of various chemical processes while maintaining energy efficiency. The integrated LED lighting system provides excellent visibility within the work area, while the low noise operation below 52 dBA ensures minimal disruption to laboratory activities.

Installation Flexibility and Operational Efficiency

The self-contained design of these fume hoods eliminates the need for external ductwork connections, making installation significantly simpler and more cost-effective compared to traditional ducted systems. One of the primary benefits of the Ductless Fume Hood is the ease of usage and the ability to move it within your facility, with modular laboratory furniture becoming one of the emerging trends in modern laboratory design. This flexibility allows laboratory managers to reconfigure workspace layouts without the constraints and expenses associated with modifying building ventilation systems. The various model configurations available, including base cupboard models (XL-DSS800, XL-DSS1000, XL-DMS1275, XL-DMS1600, XL-DLS1600) and benchtop versions (XL-DSB800, XL-DSB1000, XL-DMB1275, XL-DMB1600, XL-DLB1600), accommodate different laboratory space requirements and workflow needs. The customizable dimensions ensure proper fit within existing laboratory infrastructure while providing adequate working space for various applications. Energy efficiency is a key advantage, as these systems recirculate conditioned air rather than exhausting it to the outside, resulting in significant reduction in HVAC costs and environmental impact.

Versatile Applications and Performance Standards

Self Contained Fume Hood systems demonstrate exceptional versatility in handling diverse laboratory applications, from chemical research and pharmaceutical development to educational and industrial hygiene monitoring. The filtration capabilities effectively address acids fumes, alkali fumes, organic solvents, ammonia, formaldehyde, powders, and micron particulates, making these systems suitable for a broad spectrum of laboratory procedures. Ductless Fume Hoods are self-contained workstations that help to protect the operator and immediate environment from harmful airborne fumes and particulate, available in a variety of sizes and configurations allowing choice in efficiency, mobility and work area size. The compliance with international safety standards including CE, ISO, NFPA, EN 14175, and ASHRAE 110 ensures reliable performance and regulatory compliance across different regions and applications. These performance standards guarantee that the Self Contained Fume Hood systems meet stringent safety requirements for chemical containment and operator protection. The robust construction using chemical-resistant materials ensures long-term durability and reliability in demanding laboratory environments, while the user-friendly control systems minimize training requirements and operational complexity.

How Do Self Contained Fume Hoods Compare to Traditional Ducted Systems?

Installation Requirements and Infrastructure Considerations

The installation process for Self Contained Fume Hood systems presents significant advantages over traditional Ducted Fume Hoods in terms of simplicity, cost, and timeline requirements. Traditional ducted systems require extensive planning for ductwork installation, including modifications to building infrastructure, connection to central exhaust systems, and compliance with building codes for ventilation design. In contrast, Self Contained Fume Hood units require only electrical connections and positioning within the laboratory space, eliminating the need for costly construction work and lengthy installation periods. There are many advantages to ductless fume hoods, including energy efficiency, cost savings, and environmental benefits as compared to traditional total exhaust fume hoods. The flexibility to relocate Self Contained Fume Hood systems allows laboratory managers to adapt to changing research needs without the permanent infrastructure commitments associated with ducted systems. This portability is particularly valuable in multi-purpose laboratories or facilities undergoing expansion or reconfiguration. The reduced installation complexity also means fewer potential failure points and maintenance issues related to ductwork integrity, damper operation, and central exhaust system coordination. Laboratory managers benefit from faster deployment of safety equipment and reduced disruption to ongoing research activities during installation.

Operating Costs and Energy Efficiency Analysis

Self Contained Fume Hood systems offer substantial operating cost advantages through their energy-efficient design and reduced facility infrastructure requirements. Traditional ducted systems continuously exhaust conditioned laboratory air to the outside, requiring replacement with fresh air that must be heated, cooled, and filtered through the building's HVAC system. This process results in significant energy consumption and associated costs throughout the system's operational life. Self Contained Fume Hood technology recirculates filtered air back into the laboratory space, dramatically reducing the load on building HVAC systems and minimizing energy waste. Many are portable and can easily be relocated within the laboratory, providing increased flexibility to efficiently react to ever-changing facility requirements. The elimination of ductwork maintenance, damper adjustments, and central exhaust system coordination further reduces long-term operational costs. Filter replacement represents the primary ongoing maintenance expense, but modern filtration technology provides extended service life and predictable replacement schedules. The real-time monitoring capabilities of Xi'an Xunling Self Contained Fume Hood systems optimize filter utilization and prevent premature replacement, maximizing cost-effectiveness while maintaining safety performance.

Performance and Safety Comparison

Both Self Contained Fume Hood and traditional ducted systems provide effective protection when properly designed and operated, but they achieve containment through different mechanisms and offer distinct performance characteristics. Traditional ducted systems rely on constant air velocity and volume control through building exhaust systems, making performance dependent on central system operation and maintenance. Self Contained Fume Hood systems provide consistent performance independent of building infrastructure, with integrated monitoring systems that ensure optimal containment conditions regardless of external factors. Chemical fume hoods are the primary engineering control for capturing and removing hazardous airborne contaminants in laboratories, and when used properly will minimize or eliminate exposure while reducing the risk of injury or damage due to explosions and spills. The multi-stage filtration approach in Self Contained Fume Hood systems offers targeted protection against specific chemical classes, with activated carbon filters providing superior absorption of organic vapors compared to simple exhaust-based removal. The ability to select and optimize filtration media for specific applications allows laboratory managers to tailor protection to their unique chemical inventory and procedures. Real-time performance monitoring provides immediate feedback on system effectiveness, enabling proactive maintenance and ensuring consistent safety performance throughout the system's operational life.

What Are the Essential Maintenance and Safety Protocols for Self Contained Fume Hoods?

Filter Management and Replacement Procedures

Effective filter management represents the cornerstone of Self Contained Fume Hood maintenance, directly impacting both safety performance and operational costs throughout the system's service life. The multi-stage filtration system requires systematic monitoring and replacement of pre-filters, HEPA filters, and activated carbon filters according to manufacturer specifications and actual usage conditions. Pre-filters typically require the most frequent replacement due to their role in capturing larger particulate matter and protecting downstream filtration components from premature saturation. HEPA filters generally have longer service intervals but require careful handling during replacement to prevent contamination and ensure proper sealing within the filtration housing. Activated carbon filters demonstrate varying service life depending on the types and concentrations of chemical vapors encountered in laboratory operations. For optimal airflow and fume capture, materials should be placed as far back in the fume hood as possible, at least six inches from the front edge, to ensure fumes are properly drawn into the hood. The Xi'an Xunling Self Contained Fume Hood systems feature intelligent monitoring that tracks filter saturation levels and provides timely replacement alerts, preventing performance degradation and maintaining consistent protection. Laboratory managers should establish filter inventory management procedures to ensure replacement components are readily available when needed, minimizing system downtime and maintaining operational continuity.

Performance Testing and Calibration Requirements

Regular performance testing and calibration ensure Self Contained Fume Hood systems maintain optimal containment effectiveness and comply with safety regulations throughout their operational life. Airflow velocity measurements should be conducted at regular intervals using calibrated instruments to verify that face velocity remains within the specified range of 0.3 to 0.7 m/s. Containers and equipment should be placed toward the sides of the hood to reduce obstruction of the exhaust slots, and if possible, elevated two to three inches above the working surface using perforated or slotted shelving to minimize disruption to the airflow. Containment testing using appropriate tracer gases or smoke tests validates the system's ability to capture and contain chemical vapors under various operating conditions. Filter integrity testing ensures HEPA filters maintain their specified efficiency and have not been damaged during operation or maintenance procedures. The real-time monitoring systems integrated into Xi'an Xunling Self Contained Fume Hood models continuously track performance parameters and provide alerts when calibration or maintenance is required. Documentation of all testing results creates a performance history that supports regulatory compliance and helps identify trends that may indicate developing maintenance needs or operational issues.

User Training and Safety Protocol Implementation

Comprehensive user training and safety protocol implementation are essential for maximizing the protective benefits of Self Contained Fume Hood systems while ensuring safe and efficient laboratory operations. Laboratory personnel must understand proper work practices, including appropriate placement of materials within the hood, sash operation procedures, and recognition of alarm conditions that indicate system malfunctions. Training should cover the specific capabilities and limitations of the Self Contained Fume Hood technology, including which chemicals and procedures are appropriate for use within the system and which require alternative containment methods. Fume hoods are not the same as biosafety cabinets, and biosafety cabinets are designed for protection against exposure to biological materials and typically offer no protection against chemical vapors. Emergency procedures should be established and regularly practiced to ensure appropriate responses to system failures, filter breakthrough, or other safety incidents. Regular refresher training helps maintain awareness of proper procedures and introduces new personnel to safety protocols. The user-friendly design of Xi'an Xunling Self Contained Fume Hood systems, featuring intuitive LCD displays and clear operational indicators, supports effective training and reduces the likelihood of operator errors that could compromise safety or system performance.

Conclusion

Self Contained Fume Hood technology represents a transformative advancement in laboratory safety equipment, offering laboratory managers an effective solution that combines superior protection, operational flexibility, and cost efficiency. The comprehensive FAQ coverage demonstrates that these systems address critical laboratory needs through advanced filtration technology, simplified installation requirements, and reduced operating costs compared to traditional ducted alternatives. With their ability to capture and filter hazardous chemicals while recirculating clean air back into the laboratory environment, Self Contained Fume Hood systems provide reliable protection without the infrastructure limitations of conventional exhaust systems.

Xi'an Xunling Electronic Technology Co., Ltd. stands as a leading China Self Contained Fume Hood factory, China Self Contained Fume Hood supplier, and China Self Contained Fume Hood manufacturer, offering comprehensive solutions backed by over a decade of expertise in laboratory equipment design and production. Our commitment to delivering High Quality Self Contained Fume Hood systems at competitive Self Contained Fume Hood price points makes advanced safety technology accessible to laboratories worldwide. Whether you're seeking Self Contained Fume Hood for sale or exploring China Self Contained Fume Hood wholesale opportunities, our extensive product range and customization capabilities ensure optimal solutions for diverse laboratory requirements.

With 1,100+ employees, 21 service centers, and 5 production bases supporting rapid delivery and comprehensive after-sales service, Xi'an Xunling provides the reliability and support that laboratory managers demand. Our 5-day delivery commitment, 5-year warranty coverage, and one-stop service approach streamline procurement while ensuring long-term operational success. From initial consultation through installation, training, and ongoing maintenance support, we partner with laboratory managers to create safer, more efficient working environments that advance scientific discovery and protect personnel health.

For detailed product specifications, customization options, or technical consultation regarding Self Contained Fume Hood solutions for your laboratory, contact our expert team at xalabfurniture@163.com. Discover how Xi'an Xunling's innovative technology and comprehensive support services can transform your laboratory safety infrastructure while optimizing operational efficiency and cost-effectiveness.

References

1. American Industrial Hygiene Association. "Laboratory Ventilation Design Guidelines." AIHA Press , 3rd Edition, 2018.

2. Occupational Safety and Health Administration. "Chemical Fume Hoods Safety Requirements for Laboratories." OSHA Technical Manual , Section IV, Chapter 2, 2020.

3. ASHRAE Standard 110-2016. "Method of Testing Performance of Laboratory Fume Hoods." American Society of Heating, Refrigerating and Air-Conditioning Engineers , Atlanta, GA.

4. Scientific Equipment and Furniture Association. "Laboratory Fume Hood Performance Standards and Best Practices." SEFA Guidelines , Document SEFA-1.2, 2019.

YOU MAY LIKE

_1741166473547.webp)