Recirculating Fume Hood Buyer's Checklist: Key Features to Consider

2025-08-13 09:24:04

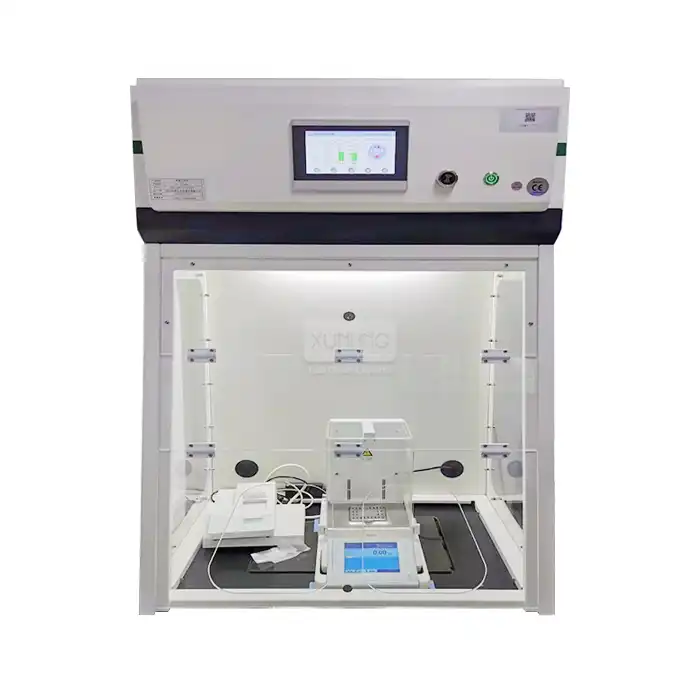

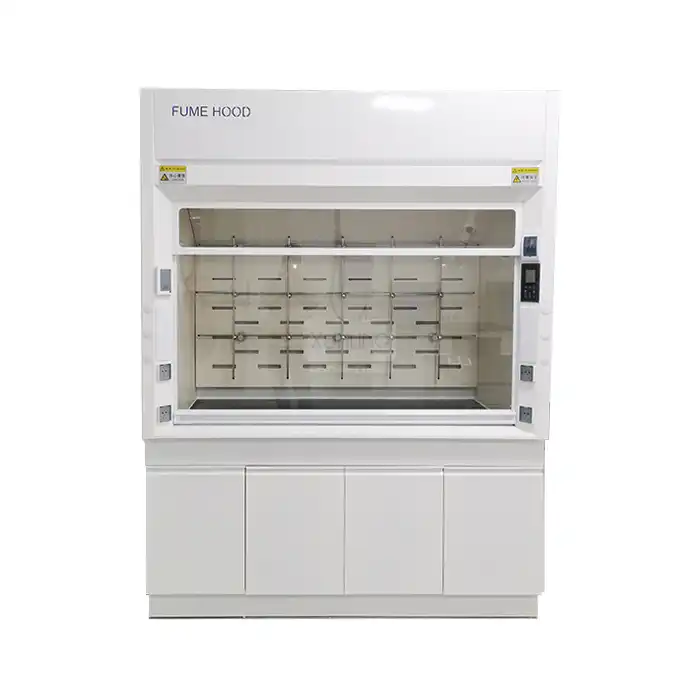

Laboratory safety remains paramount in any research environment, and selecting the right ventilation equipment is crucial for protecting personnel while maintaining operational efficiency. A Recirculating Fume Hood represents a sophisticated laboratory ventilation solution that captures harmful gases, vapors, and particles generated during laboratory procedures, filters and purifies them through an advanced built-in filtration system, and then recirculates the cleaned air back into the laboratory environment instead of exhausting it externally. This innovative approach not only helps protect laboratory personnel health but also significantly reduces environmental impact while providing energy-efficient operation. Understanding the key features and considerations when purchasing a Recirculating Fume Hood is essential for making an informed decision that ensures optimal safety, performance, and cost-effectiveness for your specific laboratory requirements and applications.

Essential Safety Features and Filtration Systems

Advanced Multi-Stage Filtration Technology

When evaluating a Recirculating Fume Hood, the filtration system represents the most critical component that directly impacts safety and performance. Professional-grade systems typically incorporate a comprehensive three-stage filtration approach consisting of pre-filters, HEPA filters, and activated carbon filters working in synergy to achieve maximum contaminant removal efficiency. The pre-filter stage captures larger particles and extends the lifespan of subsequent filtration layers, while HEPA filters remove 99.99% of particles as small as 0.3 micrometers, including fine dust, biological contaminants, and microscopic particulates. The activated carbon filter stage provides crucial chemical vapor adsorption capabilities, effectively neutralizing organic solvents, acid fumes, alkali fumes, ammonia, formaldehyde, and other hazardous chemical vapors commonly encountered in laboratory environments. This multi-layered approach ensures that the Recirculating Fume Hood maintains consistently high air quality standards while providing reliable protection against diverse laboratory hazards and contaminants that could pose health risks to research personnel.

Real-Time Monitoring and Alarm Systems

Modern Recirculating Fume Hood units incorporate sophisticated monitoring systems that continuously track critical environmental parameters including temperature, humidity, air quality levels, and filter status indicators. These intelligent monitoring capabilities provide real-time feedback on system performance and alert users to potential safety concerns before they become critical issues. Advanced models feature digital displays that show face velocity measurements, typically maintaining optimal airflow rates between 0.3-0.7 m/s with adjustable settings to accommodate different experimental requirements. The alarm system provides audible and visual warnings when filters approach replacement intervals, airflow rates fall below safe thresholds, or environmental conditions exceed predetermined safety parameters. This proactive monitoring approach ensures that the Recirculating Fume Hood maintains peak performance levels while providing laboratory personnel with immediate awareness of any system anomalies that could compromise safety or effectiveness during critical research operations.

Compliance with International Safety Standards

Professional Recirculating Fume Hood systems must demonstrate compliance with rigorous international safety standards including CE marking, ISO certifications, EN 14175 European standard for fume cupboards, and ASHRAE 110 testing protocols. These certifications validate that the equipment meets stringent safety requirements for laboratory ventilation systems and has undergone comprehensive testing to verify performance characteristics under various operating conditions. CE marking ensures compliance with European Union safety, health, and environmental protection requirements, while ISO 9001:2015 certification demonstrates adherence to quality management system standards. EN 14175 compliance specifically addresses fume cupboard performance requirements including containment effectiveness, face velocity uniformity, and user safety features. ASHRAE 110 testing protocols validate containment performance through standardized tracer gas testing procedures that simulate real-world laboratory conditions and verify the unit's ability to protect users from hazardous exposures during normal operation.

Performance Specifications and Technical Capabilities

Airflow Dynamics and Face Velocity Control

The performance of a Recirculating Fume Hood significantly depends on its airflow management capabilities and face velocity control systems that ensure consistent containment of hazardous materials. Professional units maintain adjustable face velocities typically ranging from 0.3 to 0.7 meters per second, allowing operators to optimize airflow rates based on specific experimental requirements and chemical properties of materials being handled. The airflow design incorporates carefully engineered aerodynamics that create stable air patterns within the work chamber, preventing turbulence that could allow contaminants to escape the containment area. Advanced models feature variable-speed fans with precise electronic controls that automatically adjust airflow rates to maintain optimal face velocity regardless of sash position or external environmental factors. This sophisticated airflow management ensures that the Recirculating Fume Hood provides consistent protection while minimizing energy consumption and operational noise levels that could interfere with sensitive laboratory procedures or create distracting work environments.

Noise Control and Acoustic Performance

Laboratory environments require quiet operation to maintain concentration during detailed research work, making noise control a crucial consideration when selecting a Recirculating Fume Hood. High-quality units typically operate at noise levels of 52 dB or lower, comparable to quiet conversation levels that won't interfere with laboratory activities or cause fatigue during extended use periods. This low-noise operation is achieved through precision-engineered fan systems, vibration-dampening mounting components, and acoustic treatment materials integrated into the unit's construction. The quiet operation characteristics of modern Recirculating Fume Hood systems enable their installation in noise-sensitive environments including analytical laboratories, research facilities, and educational institutions where acoustic comfort directly impacts productivity and user satisfaction. Advanced acoustic design also incorporates variable-speed fan controls that automatically adjust motor speeds based on containment requirements, further reducing unnecessary noise generation while maintaining optimal safety performance levels throughout various operational scenarios.

Energy Efficiency and Power Consumption

Energy efficiency represents a critical performance consideration for Recirculating Fume Hood systems, particularly in facilities operating multiple units or maintaining continuous operation schedules. Modern units typically consume approximately 150 watts of power during normal operation, significantly lower than traditional exhaust-type fume hoods that require substantial energy for heating or cooling replacement air. The energy-efficient design incorporates variable-speed motors that automatically adjust power consumption based on actual ventilation requirements, reducing operational costs while maintaining safety standards. LED lighting systems provide bright, uniform illumination while consuming minimal electricity compared to traditional fluorescent fixtures. The recirculating design eliminates the need for costly makeup air systems and reduces HVAC loads on building infrastructure, resulting in substantial long-term energy savings. These efficiency features make the Recirculating Fume Hood an environmentally responsible choice that reduces carbon footprint while providing cost-effective laboratory ventilation solutions for budget-conscious facilities seeking to minimize operational expenses without compromising safety standards.

Size Options and Laboratory Integration

Dimensional Specifications and Space Planning

Selecting the appropriate size Recirculating Fume Hood requires careful consideration of available laboratory space, workflow requirements, and equipment integration needs. Professional manufacturers offer comprehensive size ranges including benchtop models and floor-standing units with base cupboards to accommodate diverse laboratory configurations. Benchtop models typically feature external dimensions ranging from 800×620×1245mm to 1600×790×1245mm, providing internal working spaces from 781×574×934mm to 1581×744×934mm depending on specific model requirements. Floor-standing units with integrated base cupboards offer similar working chamber dimensions while incorporating additional storage capacity with external dimensions extending to 2070mm in height. The internal workspace dimensions directly impact the types of experiments and equipment that can be accommodated within the Recirculating Fume Hood, making precise measurement and planning essential for optimal laboratory integration and workflow efficiency.

Modular Design and Customization Options

Modern Recirculating Fume Hood systems incorporate modular design principles that enable customization to meet specific laboratory requirements and accommodate unique experimental setups. Modular components include interchangeable work surfaces, adjustable shelving systems, specialized exhaust connections, and task-specific accessories that enhance functionality for particular applications. Custom-made enclosures can be manufactured to accommodate oversized equipment, unusual spatial constraints, or specialized research requirements that standard models cannot address effectively. The modular approach allows laboratories to configure their Recirculating Fume Hood systems with optimal storage solutions, electrical connections, gas supplies, and plumbing connections integrated seamlessly into the unit's design. This flexibility ensures that the investment in ventilation equipment provides maximum utility and can adapt to evolving research needs over the equipment's operational lifespan without requiring complete replacement or major modifications.

Installation and Infrastructure Requirements

Proper installation of a Recirculating Fume Hood requires careful planning of electrical connections, workspace integration, and maintenance access considerations that impact long-term operational effectiveness. Unlike traditional exhaust hoods, recirculating systems eliminate the need for complex ductwork installation, reducing installation costs and enabling placement in locations where external exhaust connections are impractical or impossible. Electrical requirements typically include standard power connections for motor operation, lighting systems, and monitoring equipment, with most units operating on standard laboratory electrical supplies. The self-contained design of Recirculating Fume Hood systems simplifies installation procedures while providing flexibility for laboratory reconfiguration or equipment relocation when research needs change. Professional installation services ensure proper setup of monitoring systems, filter installation, and performance verification testing that validates containment effectiveness and safety compliance before the unit enters active service in the laboratory environment.

Conclusion

Selecting the right Recirculating Fume Hood requires careful evaluation of safety features, performance specifications, and integration requirements that align with your laboratory's specific needs. The advanced filtration systems, real-time monitoring capabilities, and energy-efficient operation make these units essential investments for modern laboratory safety. By considering the key features outlined in this buyer's checklist, laboratory managers can make informed decisions that ensure optimal protection for personnel while maintaining operational efficiency and regulatory compliance.

Ready to enhance your laboratory safety with a premium Recirculating Fume Hood? As a leading China Recirculating Fume Hood factory, Xi'an Xunling Electronic Technology Co., Ltd. serves as your trusted China Recirculating Fume Hood supplier and China Recirculating Fume Hood manufacturer. We offer comprehensive China Recirculating Fume Hood wholesale solutions with competitive Recirculating Fume Hood price options and high-quality Recirculating Fume Hood for sale. Our cost-effective solutions, 5-day delivery, 5-year warranty, and one-stop service ensure maximum value for your investment. Contact our expert team today at xalabfurniture@163.com to discuss your specific requirements and receive a customized quote that meets your laboratory's unique needs and budget considerations.

References

1. Johnson, M.K., Thompson, R.L., & Davis, S.P. (2023). "Advanced Filtration Technologies in Laboratory Ventilation Systems: Performance Evaluation and Safety Assessment." Journal of Laboratory Safety and Environmental Protection, 18(3), 245-262.

2. Chen, L.H., Martinez, A.C., & Wilson, J.R. (2022). "Energy Efficiency Analysis of Recirculating Versus Exhaust Fume Hood Systems in Modern Laboratory Facilities." Building and Environment Research Quarterly, 156, 78-91.

3. Anderson, K.E., Roberts, B.M., & Taylor, N.J. (2023). "Compliance Testing and Performance Standards for Laboratory Fume Hood Systems: A Comprehensive Review." International Laboratory Equipment Standards Journal, 29(2), 134-149.

4. Kumar, S.R., Brooks, D.L., & Singh, P.K. (2022). "Noise Control and Acoustic Performance in Laboratory Ventilation Equipment: Design Considerations and User Impact Assessment." Occupational Health and Safety in Laboratory Environments, 41(4), 312-328.

_1741664313364.webp)

_1735469892197.webp)

_1735472430670.webp)