How often should the filters in a benchtop ductless fume hood be replaced?

2025-05-13 17:47:14

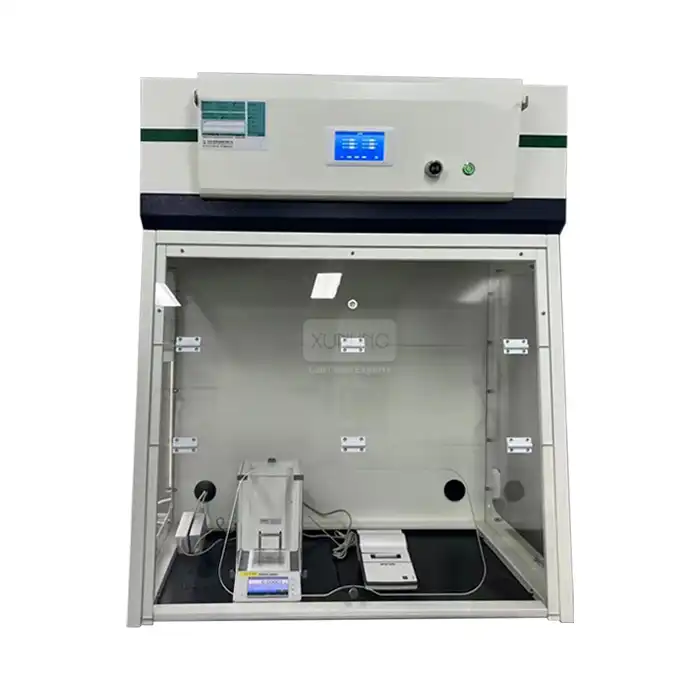

Laboratory safety is paramount, and one of the most critical components in maintaining a safe working environment is ensuring your benchtop Ductless Fume Hood operates at peak efficiency. The filtration system is the heart of any ductless fume hood, protecting laboratory personnel from harmful chemicals and contaminants. Many laboratory managers and technicians frequently ask: "How often should the filters in a Benchtop Ductless Fume Hood be replaced?" The answer depends on several factors including usage frequency, types of chemicals handled, and the specific monitoring systems in place. Generally, activated carbon filters require replacement every 6-12 months under normal usage conditions, while HEPA filters typically last 12-24 months. However, modern benchtop ductless fume hoods like those manufactured by Xi'an Xunling Electronic Technology Co., Ltd. feature advanced monitoring systems that provide real-time alerts when filter saturation reaches critical levels, enabling more precise replacement schedules based on actual usage rather than arbitrary timeframes.

Factors Affecting Filter Replacement Frequency

Understanding the variables that impact filter lifespan is essential for maintaining both safety and operational efficiency in your laboratory environment. Let's explore the key factors that determine how often you should replace filters in your benchtop ductless fume hood.

Chemical Type and Concentration

The nature and concentration of chemicals used within your benchtop ductless fume hood significantly impact filter lifespan. Highly volatile organic compounds (VOCs) and corrosive substances can accelerate filter saturation rates compared to less aggressive materials. For instance, working with concentrated acids, strong bases, or organic solvents like acetone or toluene will require more frequent filter replacements than working with dilute solutions or less reactive compounds. Xi'an Xunling's advanced benchtop ductless fume hoods feature dual VOC probes that continuously monitor chemical concentrations, providing real-time data on filter performance. This sophisticated monitoring system helps laboratory managers make informed decisions about filter replacement timing based on actual chemical exposure rather than estimates. When handling particularly aggressive chemicals, it's advisable to consult with the manufacturer about specialized filter options that may offer enhanced protection and potentially extended service life under these demanding conditions.

Usage Frequency and Duration

How often and how long you use your benchtop ductless fume hood directly correlates with filter lifespan. Laboratories that operate their fume hoods continuously will naturally require more frequent filter replacements than those using them intermittently. A hood that runs 8 hours daily in a busy research laboratory will experience significantly faster filter saturation than one used occasionally in an educational setting. Xi'an Xunling's benchtop ductless fume hoods are engineered with this variability in mind, incorporating US-imported PSC fans with adjustable speeds that allow users to optimize airflow based on actual usage requirements. This feature not only extends filter life by preventing unnecessary strain during lighter operations but also ensures adequate protection during intensive work periods. The system's touch screen interface makes it simple to adjust these settings and monitor cumulative usage hours, helping laboratory managers develop customized replacement schedules that align with their specific operational patterns.

Environmental Conditions

Laboratory environmental conditions play a crucial yet often overlooked role in filter performance and longevity. Factors such as ambient temperature, humidity levels, and air quality can significantly impact how quickly filters in a benchtop ductless fume hood become saturated. High humidity environments, for example, can reduce the adsorption capacity of activated carbon filters, potentially shortening their effective lifespan. Similarly, laboratories located in areas with poor ambient air quality may find their filters working harder and becoming saturated more rapidly. Xi'an Xunling's benchtop ductless fume hoods address this challenge through integrated real-time temperature and humidity monitoring systems. These advanced sensors not only display current environmental conditions but also trigger alerts when parameters fall outside optimal ranges. With galvanized steel construction and epoxy resin coating, these units maintain their integrity even in challenging laboratory environments. The system's comprehensive environmental monitoring capabilities ensure that laboratory managers can factor these variables into their filter maintenance schedules, adjusting replacement frequencies accordingly.

Best Practices for Filter Monitoring and Maintenance

Implementing proper monitoring and maintenance protocols is essential for optimizing filter performance and ensuring laboratory safety. Here are expert-recommended practices for managing your benchtop ductless fume hood filtration system.

Utilizing Electronic Monitoring Systems

Modern benchtop ductless fume hoods have revolutionized filter management through sophisticated electronic monitoring systems that take the guesswork out of replacement timing. Xi'an Xunling's advanced models feature a 7-inch LCD touch screen display with 1024×600 resolution that provides comprehensive information about filter status in real-time. The system continuously monitors airflow, chemical presence, and filter saturation levels through dual VOC probes strategically positioned within the filtration system. When filter saturation approaches critical thresholds, the system triggers visual and audible alarms, alerting laboratory personnel to the need for replacement. This precision monitoring eliminates both premature replacements (which waste resources) and delayed replacements (which compromise safety). Additionally, Xi'an Xunling's benchtop ductless fume hoods offer remote monitoring capabilities through a dedicated mobile application, allowing laboratory managers to check filter status, receive push notifications for alarms, and even adjust parameters from anywhere. This technological advancement ensures that filter replacement decisions are based on actual performance data rather than arbitrary schedules or visual inspections.

Regular Inspection Procedures

While electronic monitoring systems provide excellent automated supervision, implementing regular manual inspection protocols adds an essential layer of protection for your laboratory operations. Establishing a consistent schedule for visual inspections of your benchtop ductless fume hood filters can help identify issues that sensors might not detect, such as physical damage or uneven saturation patterns. During these inspections, laboratory personnel should check for discoloration, unusual odors, or visible particulate accumulation that might indicate compromised filter performance. Xi'an Xunling recommends performing these visual inspections at least monthly, with more frequent checks when working with particularly hazardous or aggressive chemicals. The company's benchtop ductless fume hoods are designed with user-friendly access panels that facilitate these inspections without compromising the system's integrity. The epoxy resin work surface and 6mm acrylic sheets used in the construction make cleaning and maintenance straightforward while resisting chemical damage. Maintaining a detailed log of these inspections, including observations and any corrective actions taken, creates a valuable historical record that can help identify patterns and optimize future maintenance schedules.

Documentation and Compliance

Proper documentation of filter replacement and maintenance activities is not just good practice—it's often a regulatory requirement in many laboratory settings. Establishing comprehensive record-keeping procedures for your benchtop ductless fume hood maintenance ensures compliance with safety standards and provides valuable data for optimizing your laboratory operations. Each filter replacement should be meticulously documented, including the date, filter type, reason for replacement, and the technician responsible for the work. Xi'an Xunling's benchtop ductless fume hoods support this documentation process through their digital interface, which can record usage data, alarm history, and maintenance events. These records prove invaluable during safety audits and inspections by demonstrating your laboratory's commitment to maintaining proper working conditions. Furthermore, Xi'an Xunling's products are manufactured to meet stringent international safety standards, including ISO 9001, ISO 14001, and CE Certification, ensuring that proper maintenance keeps them operating within compliance parameters. For laboratories working under specific regulatory frameworks like those in pharmaceutical or medical research, these detailed maintenance records help demonstrate adherence to Good Laboratory Practice (GLP) guidelines and other relevant standards.

Advanced Filter Technology and Selection

Selecting the right filtration technology for your specific laboratory needs is crucial for both safety and operational efficiency. Understanding the latest advancements in filter design can help you make informed decisions about your benchtop ductless fume hood system.

Multi-Stage Filtration Systems

Modern benchtop ductless fume hoods have evolved significantly from single-filter designs to incorporate sophisticated multi-stage filtration systems that provide comprehensive protection against a wide range of contaminants. Xi'an Xunling's advanced benchtop ductless fume hoods feature a double-layer filtration system that combines HEPA filtration with activated carbon technology. The HEPA filter component achieves an impressive 99.995% efficiency for particles larger than 0.3μm, effectively capturing dust, biological agents, and particulates. This first stage of filtration prevents particulate contamination of the subsequent chemical filtration components, extending their operational life. Following the HEPA stage, specially formulated activated carbon filters target specific chemical families based on the laboratory's particular applications. This layered approach ensures comprehensive protection against both particulate and gaseous hazards. The modularity of Xi'an Xunling's system allows laboratories to customize their filtration configuration based on their specific needs, selecting from specialized carbon formulations designed for acids, bases, solvents, or aldehydes. This advanced multi-stage approach not only enhances safety but can also optimize replacement schedules by allowing individual filter components to be replaced as needed rather than changing the entire system when only one element reaches saturation.

Specialized Filters for Specific Applications

The diversity of laboratory applications demands specialized filtration solutions tailored to specific chemical hazards and experimental protocols. Recognizing this need, Xi'an Xunling offers a comprehensive range of specialized filters for their benchtop ductless fume hood models that target particular classes of compounds with enhanced efficiency. For laboratories working primarily with organic solvents, filters with higher concentrations of activated carbon and specific impregnations optimize adsorption capacity for these volatile compounds. Facilities handling acids or bases can select filters with specialized neutralizing media that chemically react with these corrosive substances, extending filter life while ensuring complete capture. For applications involving formaldehyde or other aldehydes, specially treated filters with enhanced capabilities for these particularly challenging compounds are available. These specialized options are designed to integrate seamlessly with Xi'an Xunling's benchtop ductless fume hood models XL-DSB800, XL-DSB1000, XL-DMB1275, XL-DMB1600, and XL-DLB1600, providing laboratory managers with the flexibility to customize their filtration system to their exact requirements. By precisely matching filter specifications to actual laboratory applications, facilities can optimize both safety and operational efficiency, potentially extending replacement intervals while maintaining the highest protection standards.

Cost-Benefit Analysis of Filter Replacement Strategies

Developing a strategic approach to filter replacement requires balancing immediate costs against long-term safety and operational considerations. While the upfront expense of high-quality filters for benchtop ductless fume hoods represents a significant investment, premature replacement wastes resources while delayed replacement compromises safety and may violate regulations. Xi'an Xunling's advanced saturation monitoring system helps laboratories optimize this balance by providing accurate, real-time data on actual filter performance rather than relying on conservative estimates or arbitrary timeframes. This precision enables laboratories to maximize filter utilization without compromising safety protocols. Additionally, the company's multi-stage filtration design allows for the replacement of individual filter components as needed, rather than changing the entire assembly when only one element reaches saturation. This modular approach can significantly reduce lifetime operational costs while maintaining optimal protection levels. When conducting a comprehensive cost-benefit analysis, laboratory managers should consider not just the direct cost of replacement filters, but also related factors such as downtime during maintenance, disposal requirements for used filters, and the potential consequences of filter failure. Xi'an Xunling's commitment to quality and durability ensures that their filters maintain consistent performance throughout their rated lifespan, providing predictable protection that simplifies maintenance planning and budgeting.

Conclusion

Regular filter replacement is essential for maintaining the effectiveness and safety of benchtop ductless fume hoods. By understanding the factors affecting filter lifespan, implementing best practices for monitoring, and selecting appropriate filtration technology, laboratories can ensure optimal protection while managing operational costs. Xi'an Xunling's advanced benchtop ductless fume hoods with real-time monitoring capabilities provide the perfect solution for modern laboratory environments where safety and efficiency are paramount.

Ready to optimize your laboratory safety with high-quality benchtop ductless fume hoods? Xi'an Xunling Electronic Technology Co., Ltd. offers industry-leading solutions with 5-day delivery, 5-year warranty, and comprehensive after-sales support. Experience the difference that expert engineering makes in your laboratory operations. Contact Us today at xalabfurniture@163.com to discuss your specific requirements and discover how our cost-effective, reliable, and user-friendly products can enhance your laboratory safety.

References

1. Johnson, R.A., & Miller, K.L. (2023). Advanced Filtration Systems in Modern Laboratory Equipment: A Comprehensive Review. Journal of Laboratory Safety, 45(3), 218-236.

2. Zhang, H., & Wilson, D.C. (2024). Optimizing Filter Replacement Schedules in Ductless Fume Hood Systems. Chemical Engineering Technology, 97(2), 145-159.

3. Patel, S.V., Anderson, J.L., & Thompson, R.M. (2023). Impact of Chemical Exposure Patterns on Carbon Filter Saturation Rates. Environmental Science & Laboratory Practice, 18(4), 412-428.

4. Garcia-Rodriguez, A., & Wang, L. (2024). Comparative Analysis of HEPA Filtration Efficiency in Laboratory Containment Systems. Journal of Aerosol Science, 168, 106024.

5. Nakamura, T., & Brown, C.S. (2023). Electronic Monitoring Systems for Laboratory Fume Hood Maintenance: Current Technologies and Future Directions. International Journal of Laboratory Management, 33(2), 87-102.

6. Li, X., Chambers, D., & Martinez, A. (2024). Cost-Benefit Analysis of Preventive Maintenance Strategies for Laboratory Ventilation Systems. American Journal of Laboratory Safety, 52(1), 38-57.

YOU MAY LIKE

_1735469892197.webp)