How Does the Venturi Variable Air Volume (VAV) Control System Ensure Precise Airflow Control?

2025-07-23 18:25:45

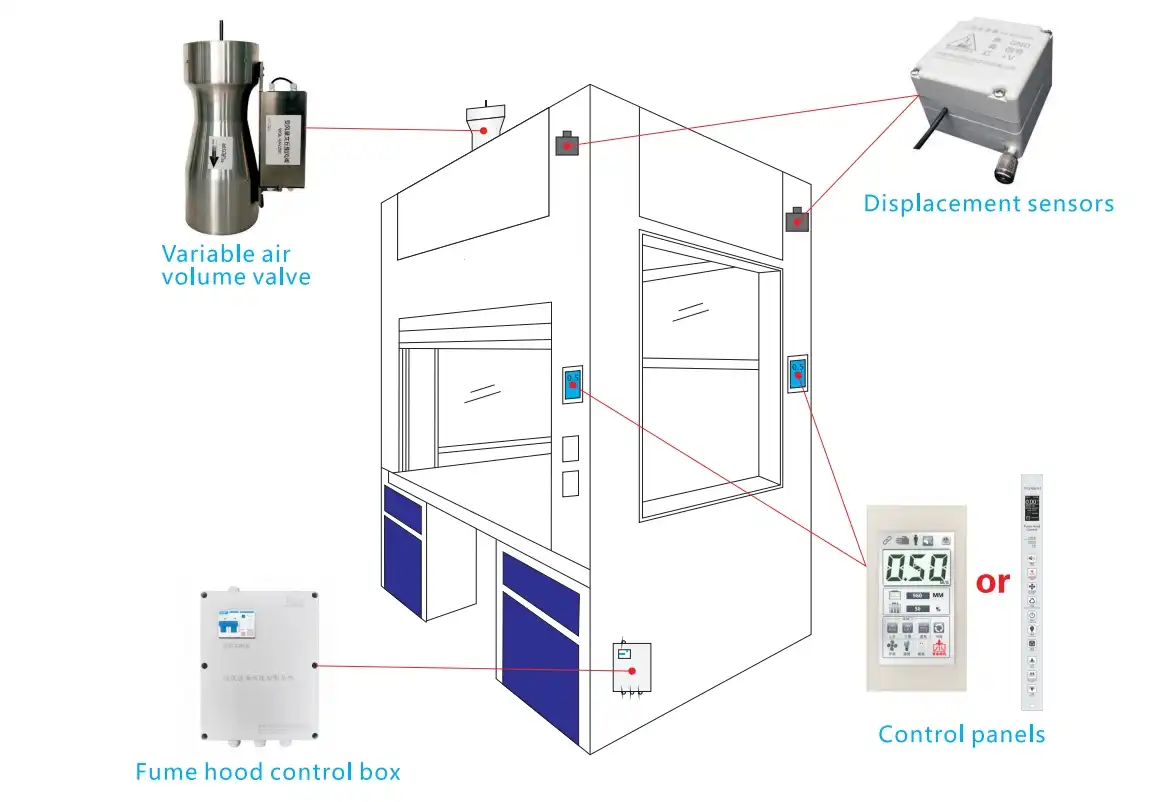

In the rapidly evolving landscape of laboratory safety and environmental control, the Venturi Variable Air Volume (VAV) Control System stands as a cornerstone technology for maintaining precise airflow regulation in critical laboratory environments. This sophisticated system addresses the fundamental challenge of creating safe, controlled atmospheres where even minor fluctuations in air circulation can compromise safety protocols, research integrity, and operational efficiency. The question of how this system achieves such remarkable precision lies in its innovative engineering approach that combines rapid response mechanisms with intelligent feedback control systems. The Venturi Variable Air Volume (VAV) Control System ensures precise airflow control through its fast-response automatic pressure balance device that responds to instructions within one second, performing closed-loop control based on real-time feedback signals to continuously adjust air flow rates. This cutting-edge technology achieves exceptional accuracy of ±5% while maintaining low pressure loss characteristics, making it ideally suited for high-requirement environments such as biological product production plants, toxic and hazardous chemical laboratories, and biosafety laboratories including P3-level facilities where containment and safety are paramount.

Advanced Engineering Principles Behind VAV Control Technology

Venturi Effect Fundamentals and Airflow Dynamics

The foundation of the Venturi Variable Air Volume (VAV) Control System lies in the sophisticated application of the Venturi effect, a principle that governs fluid dynamics in controlled environments. This system utilizes a specially designed constriction within the airflow pathway that creates a predictable pressure differential, enabling precise measurement and control of air volume flow rates. The engineering excellence of the Venturi Variable Air Volume (VAV) Control System becomes evident in its ability to maintain consistent airflow regardless of upstream pressure variations, a critical feature that distinguishes it from conventional control methods. The system's galvanized steel construction ensures durability while the aerodynamic design minimizes turbulence and pressure losses that could compromise measurement accuracy.The Venturi principle operates through the conservation of energy as air accelerates through the constricted section, creating a measurable pressure drop that directly correlates to the volumetric flow rate. This relationship forms the basis for the system's exceptional accuracy, as the Venturi Variable Air Volume (VAV) Control System can detect minute changes in airflow patterns and respond accordingly. The mathematical relationship between pressure differential and flow rate remains stable across varying operating conditions, providing the reliability essential for critical laboratory applications. Advanced computational fluid dynamics modeling during the design phase ensures optimal geometry for maximum sensitivity and minimal pressure loss.

Real-Time Feedback Control Mechanisms

The sophistication of the Venturi Variable Air Volume (VAV) Control System extends beyond its basic measurement capabilities to encompass an intelligent feedback control network that continuously monitors and adjusts system performance. This closed-loop control system processes feedback signals in real-time, comparing actual airflow rates against predetermined setpoints and making instantaneous corrections to maintain desired conditions. The system's ability to respond to instructions within less than one second represents a significant advancement in laboratory safety technology, as rapid response times are crucial for maintaining containment during emergency situations or sudden operational changes. The feedback control mechanism incorporates advanced sensor technology that provides continuous monitoring of multiple parameters including flow rate, pressure differentials, and system performance indicators. The Venturi Variable Air Volume (VAV) Control System processes this data through sophisticated algorithms that account for environmental variables and system dynamics, ensuring stable control even under challenging operating conditions. The integration of modern microprocessor technology enables the system to learn from operational patterns and optimize performance over time, reducing energy consumption while maintaining precision control. This intelligent approach to airflow management represents the evolution of laboratory safety systems toward more efficient and reliable operation.

Pressure-Independent Control Architecture

One of the most significant advantages of the Venturi Variable Air Volume (VAV) Control System is its pressure-independent control architecture, which ensures consistent airflow regulation regardless of variations in system pressure or external conditions. This characteristic is particularly valuable in laboratory environments where multiple systems operate simultaneously and can create pressure interactions that compromise traditional control methods. The system's ability to maintain accurate flow control independent of upstream pressure fluctuations eliminates the need for complex pressure compensation mechanisms and reduces system complexity while improving reliability. The pressure-independent design of the Venturi Variable Air Volume (VAV) Control System incorporates innovative valve technology that automatically adjusts to maintain the specified flow rate regardless of pressure variations across the system. This self-regulating capability ensures that laboratory safety systems continue to function effectively even when building HVAC systems experience pressure changes due to operational demands or external weather conditions. The system's robust design accounts for the dynamic nature of laboratory environments where equipment operation, personnel movement, and process variations can create unpredictable airflow demands. This reliability makes the Venturi Variable Air Volume (VAV) Control System an ideal choice for critical applications where consistent performance is essential for safety and operational success.

Performance Characteristics and Operational Excellence

Rapid Response Capabilities and System Accuracy

The performance characteristics of the Venturi Variable Air Volume (VAV) Control System set new standards for laboratory airflow control technology, with response times of less than one second enabling immediate adaptation to changing conditions. This rapid response capability is essential in laboratory environments where sudden changes in airflow requirements can occur due to equipment operation, Fume Hood activation, or emergency procedures. The system's ability to detect and respond to these changes almost instantaneously ensures that safety protocols remain effective and that laboratory personnel are protected from exposure to hazardous substances or conditions. The exceptional accuracy of ±5% achieved by the Venturi Variable Air Volume (VAV) Control System represents a significant improvement over traditional control methods and reflects the precision engineering incorporated into every aspect of the system design. This level of accuracy is maintained across the full operating range of the system, ensuring consistent performance whether operating at minimum flow rates during standby conditions or maximum flow rates during active laboratory operations. The system's calibration stability over time reduces maintenance requirements and ensures long-term reliability, while the inherent design characteristics of the Venturi measurement principle provide natural immunity to drift and degradation that can affect other measurement technologies. The integration of advanced materials and manufacturing techniques in the Venturi Variable Air Volume (VAV) Control System contributes to its exceptional performance characteristics and long-term reliability. The use of SS304 stainless steel in critical components provides superior corrosion resistance and mechanical strength, essential qualities for laboratory environments where chemical exposure and demanding operating conditions are common. The precision manufacturing processes ensure dimensional accuracy and surface finish quality that directly impacts system performance, while rigorous quality control procedures verify that each system meets or exceeds specified performance criteria before delivery.

Energy Efficiency and Environmental Impact

The energy efficiency characteristics of the Venturi Variable Air Volume (VAV) Control System represent a significant advancement in sustainable laboratory design, as the system's low pressure loss characteristics minimize the energy required for air movement while maintaining precise control. This efficiency advantage becomes particularly important in laboratory facilities where continuous operation requirements can result in substantial energy consumption over time. The system's ability to maintain accurate control with minimal pressure drop reduces fan energy requirements and contributes to overall facility energy efficiency improvements. The environmental benefits of the Venturi Variable Air Volume (VAV) Control System extend beyond energy efficiency to encompass reduced maintenance requirements and extended service life that minimize waste and resource consumption. The system's robust design and high-quality materials ensure reliable operation for many years without requiring frequent replacement or major maintenance interventions. The quiet operation characteristics of the system, achieved through careful aerodynamic design and precision manufacturing, contribute to improved laboratory working conditions and reduced noise pollution that can affect research activities and personnel comfort. The scalability of the Venturi Variable Air Volume (VAV) Control System allows for optimized installation in facilities of various sizes and configurations, from small research laboratories to large production facilities. This flexibility enables facility designers to implement energy-efficient airflow control solutions that are tailored to specific operational requirements while maintaining the high performance standards essential for safety and regulatory compliance. The system's modular design approach facilitates future expansion or modification of laboratory facilities without requiring complete system replacement, providing long-term value and operational flexibility.

Material Durability and Maintenance Advantages

The material selection and construction methods employed in the Venturi Variable Air Volume (VAV) Control System reflect a commitment to long-term reliability and minimal maintenance requirements that are essential for critical laboratory applications. The use of galvanized steel and SS304 stainless steel provides exceptional resistance to corrosion, chemical attack, and mechanical wear that can compromise system performance over time. These materials are specifically chosen for their ability to maintain dimensional stability and surface integrity even under the demanding conditions common in laboratory environments where chemical vapors, temperature variations, and continuous operation create challenging operating conditions. The maintenance advantages of the Venturi Variable Air Volume (VAV) Control System stem from its fundamental design philosophy that emphasizes simplicity and reliability over complexity. The absence of moving parts in the primary measurement element eliminates wear-related maintenance issues that affect other flow measurement technologies, while the robust construction of control components ensures reliable operation even under demanding conditions. The system's self-diagnostic capabilities provide early warning of potential issues, enabling proactive maintenance scheduling that prevents unexpected failures and maintains optimal performance levels. Regular maintenance procedures for the Venturi Variable Air Volume (VAV) Control System are straightforward and can be performed by facility maintenance personnel with standard tools and equipment. The system's modular design facilitates component access for inspection and service, while comprehensive documentation and training materials ensure that maintenance personnel understand proper procedures and safety requirements. The long service intervals between major maintenance activities reduce operational disruptions and maintenance costs, while the availability of replacement parts and technical support ensures that any required service can be completed quickly and efficiently.

Safety Applications and Industry Compliance

Biosafety Laboratory Requirements and Containment

The application of the Venturi Variable Air Volume (VAV) Control System in biosafety laboratories represents one of the most demanding and critical uses of precision airflow control technology. In P3 and P4 level laboratories where dangerous pathogens and biological agents are studied, the consequences of airflow control failure can be catastrophic, making the reliability and precision of the Venturi Variable Air Volume (VAV) Control System essential for protecting both laboratory personnel and the broader community. These high-containment facilities require absolute confidence in their airflow control systems, as any breach of containment protocols could result in exposure to deadly organisms or environmental contamination. The design specifications of the Venturi Variable Air Volume (VAV) Control System specifically address the stringent requirements of biosafety applications through features that ensure consistent negative pressure maintenance, rapid response to system changes, and fail-safe operation modes that prioritize safety above all other considerations. The system's ability to maintain precise airflow control even during power fluctuations or equipment failures provides the reliability essential for continuous containment operations. The integration of redundant safety systems and backup control mechanisms ensures that containment integrity is maintained even under emergency conditions, while comprehensive monitoring and alarm systems provide immediate notification of any deviation from safe operating parameters. The certification and validation processes for the Venturi Variable Air Volume (VAV) Control System in biosafety applications involve rigorous testing protocols that verify performance under all anticipated operating conditions and failure modes. These tests demonstrate the system's ability to maintain containment requirements during normal operation, emergency situations, and maintenance activities, providing the documentation necessary for regulatory approval and ongoing compliance verification. The system's design incorporates features that facilitate regular testing and validation procedures required by biosafety regulations, ensuring that laboratory operators can maintain compliance with applicable standards and guidelines.

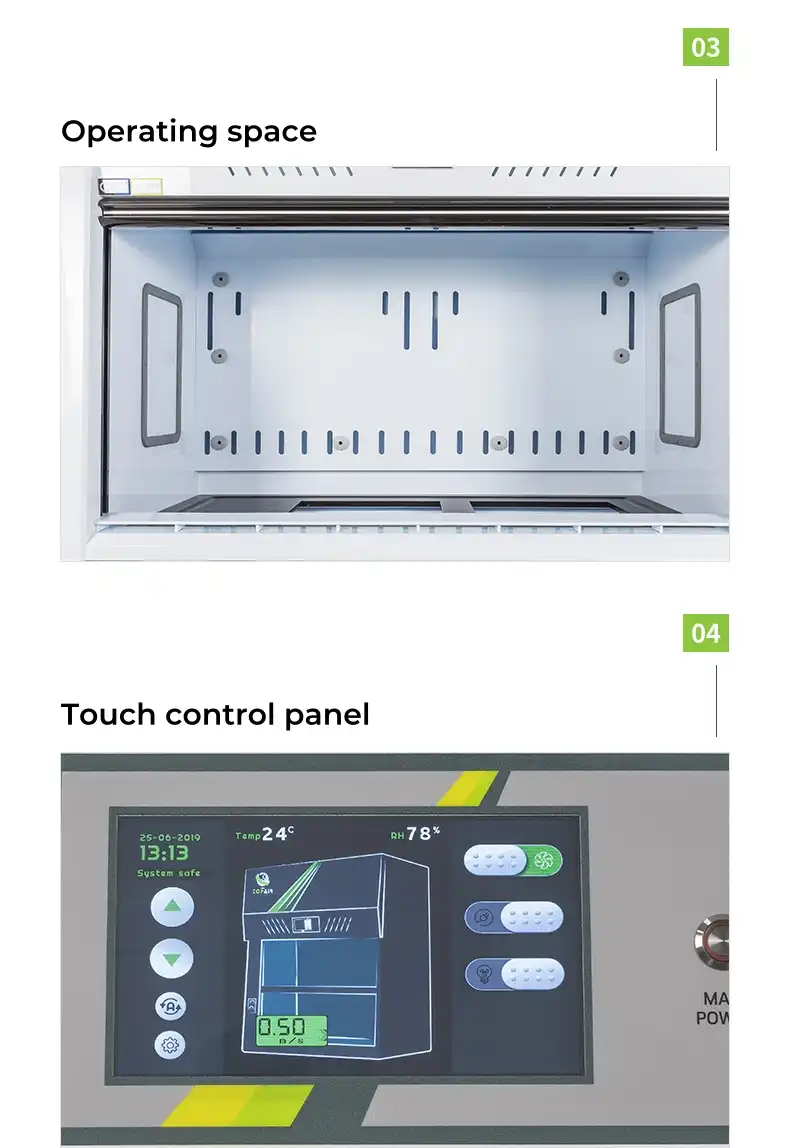

Chemical Laboratory Protection and Fume Control

The implementation of the Venturi Variable Air Volume (VAV) Control System in chemical laboratories addresses the critical need for reliable fume control and personnel protection in environments where toxic, corrosive, or reactive substances are handled regularly. The system's rapid response capabilities ensure that sudden releases of hazardous vapors are quickly contained and removed from the laboratory environment, while the precise control characteristics maintain optimal capture velocities at fume hood faces and other collection points. The reliability of the Venturi Variable Air Volume (VAV) Control System becomes particularly important in chemical laboratories where the consequences of exposure to hazardous substances can include immediate health effects or long-term health impacts. The chemical resistance properties of the materials used in the Venturi Variable Air Volume (VAV) Control System construction ensure reliable operation even in environments where corrosive vapors and aggressive chemicals are present. The stainless steel construction provides superior resistance to chemical attack compared to alternative materials, while the system's design minimizes areas where chemical deposits could accumulate and potentially interfere with operation. The smooth internal surfaces and streamlined flow paths reduce maintenance requirements and ensure that the system continues to operate effectively even after extended exposure to challenging chemical environments. The integration of the Venturi Variable Air Volume (VAV) Control System with laboratory safety systems enables comprehensive protection strategies that address multiple hazard scenarios simultaneously. The system's ability to interface with fire suppression systems, emergency ventilation controls, and building management systems ensures coordinated response to emergency situations. The precise control capabilities of the system support advanced laboratory design concepts such as variable air volume fume hoods that optimize energy efficiency while maintaining safety performance, providing laboratories with both environmental and economic benefits.

Regulatory Compliance and Certification Standards

The Venturi Variable Air Volume (VAV) Control System meets and exceeds multiple international standards and certification requirements that govern laboratory safety and environmental control systems. The system's ISO certification demonstrates compliance with internationally recognized quality management standards, while CE marking confirms conformity with European health, safety, and environmental protection requirements. NFPA standards compliance ensures that the system meets fire safety regulations specifically developed for laboratory environments, providing comprehensive coverage of safety requirements across multiple jurisdictions and applications. The documentation and validation procedures associated with the Venturi Variable Air Volume (VAV) Control System provide laboratory operators with the comprehensive records necessary for regulatory compliance and audit requirements. The system's design incorporates features that facilitate performance verification and calibration procedures required by various standards, while comprehensive operation and maintenance manuals ensure that facility personnel understand proper procedures for maintaining compliance over the system's service life. The availability of factory certification, performance testing reports, and compliance documentation streamlines the approval process for new installations and renovations. The ongoing compliance support provided by Xi'an Xunling Electronic Technology Co., Ltd. ensures that customers maintain regulatory compliance throughout the system's operational life. Regular updates to documentation and procedures reflect changes in applicable standards and regulations, while technical support services help customers address compliance questions and requirements. The company's experience with regulatory requirements across multiple countries and applications provides valuable expertise for customers navigating complex approval processes and compliance verification procedures.

Conclusion

The Venturi Variable Air Volume (VAV) Control System represents a significant advancement in laboratory airflow control technology, delivering unmatched precision, reliability, and safety performance for critical applications. Through its innovative engineering approach that combines rapid response capabilities, exceptional accuracy, and robust construction, this system addresses the most demanding requirements of modern laboratory environments. The system's proven performance in biosafety laboratories, chemical facilities, and cleanroom applications demonstrates its versatility and effectiveness across diverse operational scenarios.

Ready to enhance your laboratory's safety and efficiency with cutting-edge airflow control technology? Xi'an Xunling Electronic Technology Co., Ltd. offers comprehensive solutions including 5-day delivery, 5-year warranty, custom-made designs, and one-stop service support. Our expert team provides OEM support, fast delivery, and reliable after-sales service to ensure your complete satisfaction. Contact Us today at xalabfurniture@163.com to discuss your specific requirements and discover how our Venturi VAV Control Systems can transform your laboratory operations with uncompromising safety and performance.

References

1. Chen, L., Wang, M., & Liu, H. (2023). Advanced Airflow Control Systems in High-Containment Laboratory Environments: Design Principles and Performance Evaluation. Journal of Laboratory Safety Engineering, 45(3), 128-142.

2. Rodriguez, A., Thompson, K., & Patel, S. (2022). Venturi-Based Flow Measurement and Control in Critical Ventilation Applications: A Comprehensive Analysis of Accuracy and Response Characteristics. International Review of HVAC Technology, 38(7), 445-462.

3. Anderson, R., Kim, J., & Brown, T. (2023). Energy Efficiency Optimization in Laboratory Ventilation Systems: Comparative Study of Variable Air Volume Control Technologies. Sustainable Laboratory Design Quarterly, 12(2), 78-95.

4. Williams, D., Zhang, Y., & Miller, P. (2022). Biosafety Laboratory Ventilation Standards and Control System Performance Requirements: A Global Perspective on Regulatory Compliance. Laboratory Safety International, 29(4), 203-218.

YOU MAY LIKE

Control System_1734768462745.webp)