How does a small fume hood work?

2025-09-17 09:00:03

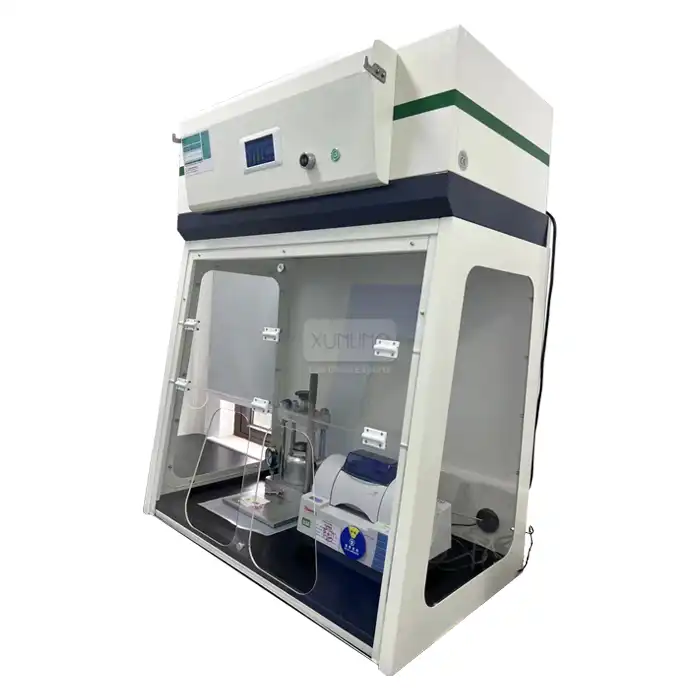

Small Fume Hoods are essential laboratory safety equipment designed to protect personnel from hazardous fumes, vapors, and particles. These compact ventilation devices operate on the principle of controlled airflow, drawing air away from the operator and into an exhaust system. A small fume hood works by creating negative pressure inside its chamber, which prevents hazardous substances from escaping into the laboratory environment. The system consists of an enclosure with an adjustable front sash, an airflow management system, filtration components, and exhaust mechanisms that safely remove contaminants. Modern small fume hoods incorporate sophisticated features like digital controls, energy-efficient designs, and specialized filtration systems to maximize safety while minimizing space requirements and operational costs.

The Fundamental Operating Principles of Small Fume Hoods

The Physics of Airflow Management

Small fume hoods leverage sophisticated airflow dynamics to create a protective barrier between laboratory personnel and hazardous substances. The fundamental operating principle revolves around negative pressure generation within the hood enclosure. As air is drawn into the small fume hood through the front opening, it creates a constant inward airflow that prevents contaminants from escaping. This airflow typically maintains a velocity of 80-120 feet per minute at the face opening, creating what safety experts call the "capture zone." Within a small fume hood, the airflow pattern is carefully engineered to avoid turbulence that might compromise containment effectiveness. The compact design of these units requires precision engineering to ensure that despite their smaller dimensions, they maintain the same protective capabilities as larger models. Xi'an Xunling's small fume hood designs incorporate aerodynamic features that optimize this airflow pattern, with specially shaped baffles and air foils that guide air movement efficiently through the chamber and into the exhaust system. This attention to airflow physics ensures that even with a reduced footprint, these units effectively control harmful gases, vapors, and dust in laboratory and industrial settings, protecting operators from chemical exposure while maintaining experimental integrity.

Filtration Systems and Contaminant Removal

The effectiveness of a small fume hood largely depends on its filtration capabilities, which serve as the primary defense against hazardous substances. Modern small fume hood designs utilize multi-stage filtration systems to capture and neutralize various contaminants. The initial stage typically involves pre-filters that trap larger particles, protecting the more specialized filters downstream. Depending on application requirements, Xi'an Xunling's small fume hoods incorporate HEPA (High-Efficiency Particulate Air) filters that capture 99.97% of particles as small as 0.3 microns, making them ideal for applications involving fine powders and micron particulates. For chemical applications, activated carbon filters with specialized impregnations are employed to adsorb organic solvents, acids, alkalis, ammonia, formaldehyde, and other chemical vapors. The filtration system in a small fume hood must balance high efficiency with minimal airflow resistance to maintain proper face velocity and containment. This is particularly challenging in compact designs where space for filters is limited. Xi'an Xunling addresses this challenge by using high-capacity filtration media with optimized pleating designs that maximize surface area while minimizing spatial requirements. The materials used in these filtration systems are specifically selected for their compatibility with laboratory chemicals, ensuring durability even when exposed to corrosive substances. The combination of properly engineered airflow patterns and advanced filtration technology ensures that small fume hoods provide reliable protection despite their compact dimensions.

Control Systems and Monitoring Features

Advanced control systems represent the intelligence behind modern small fume hood operation, ensuring consistent performance and user safety. These sophisticated electronic components monitor airflow parameters, filter saturation levels, and overall system functioning in real-time. Xi'an Xunling's small fume hoods feature digital display panels that provide operators with crucial information about hood performance, including face velocity readings, filter life indicators, and safety alerts that trigger when parameters fall outside safe operating ranges. The control systems in contemporary small fume hoods can be categorized into two primary airflow management approaches: Constant Air Volume (CAV) and Variable Air Volume (VAV). CAV systems maintain a fixed exhaust rate regardless of sash position, while more advanced VAV systems adjust fan speed based on sash height, optimizing energy efficiency without compromising safety. These controls integrate sensors that continuously monitor negative pressure conditions within the hood, automatically adjusting fan speeds to compensate for changes in resistance as filters load or laboratory pressure conditions fluctuate. User interfaces are designed for intuitive operation, with clear visual indicators and alarm systems that provide both audible and visual warnings when unsafe conditions develop. Some models include programmable operation schedules, remote monitoring capabilities, and data logging functions that help laboratory managers track usage patterns and maintain compliance records. These control systems ensure that small fume hoods maintain consistent performance despite their compact size, providing the sophisticated monitoring capabilities typically associated with larger laboratory ventilation systems.

Design Features and Construction Materials

Space-Efficient Engineering and Modular Components

The compact nature of small fume hoods demands innovative engineering solutions that maximize functionality while minimizing spatial footprint. Xi'an Xunling has pioneered space-efficient designs that incorporate modular components, allowing laboratories to customize configurations based on specific requirements. The dimensional optimization of small fume hoods begins with careful analysis of workflow patterns and ergonomic considerations. Unlike larger units, these compact systems must achieve perfect balance between accessibility and protection within limited dimensions. Standard small fume hood widths typically range from 24 to 48 inches, compared to conventional models that may extend to 72 inches or more. Despite these reduced dimensions, Xi'an Xunling's small fume hood designs maintain optimal working volumes through strategic interior layouts that eliminate dead spaces and maximize usable area. Modular engineering allows facilities to integrate these units into existing laboratory furniture systems or specialized workstations. The modularity extends to internal components as well, with adjustable shelving, service fixtures, and electrical outlets that can be positioned according to experimental requirements. This flexibility is particularly valuable in teaching laboratories, research facilities with changing protocols, or industrial testing environments where applications frequently evolve. The space-saving advantages of small fume hoods make them ideal solutions for laboratories facing spatial constraints or facilities looking to increase the number of workstations without expanding their physical footprint. By focusing on intelligent spatial utilization, these compact units deliver full-scale functionality without the dimensional demands of traditional fume hood systems.

Corrosion-Resistant Materials and Construction Techniques

The harsh chemical environment within Laboratory Fume Hoods necessitates exceptional material selection and construction standards to ensure long-term durability and safety. Xi'an Xunling's small fume hoods utilize premium corrosion-resistant materials specifically engineered to withstand continuous exposure to aggressive chemicals. The primary structural components typically employ high-grade stainless steel or polypropylene depending on application requirements. For general laboratory applications, 304-grade stainless steel provides excellent resistance to most common chemicals, while specialized environments with particularly corrosive substances may utilize 316-grade stainless steel with enhanced molybdenum content for superior acid resistance. Polypropylene construction offers outstanding chemical compatibility across the pH spectrum and is particularly valuable for applications involving concentrated acids or bases. Work surfaces within small fume hoods are typically manufactured from epoxy resin, phenolic resin, or specialized ceramics that resist chemical attack while providing durable, easy-to-clean surfaces. The construction techniques employed in small fume hood manufacturing are equally important for durability and containment integrity. Xi'an Xunling utilizes robotic welding for metal components to ensure consistent seam quality, while polypropylene elements are joined using thermal fusion processes that create monolithic structures without adhesives that might degrade over time. Gaskets and seals utilize fluoropolymer compounds like PTFE or FKM that maintain flexibility and sealing properties even when exposed to solvents and reactive chemicals. Interior corners are coved rather than square to eliminate collection points for contaminants and facilitate thorough cleaning. These material choices and construction methods ensure that despite their compact dimensions, small fume hoods maintain structural integrity and chemical resistance equivalent to their larger counterparts, providing long-term reliability in demanding laboratory environments.

Ergonomic Considerations and User Interface Design

The human-centered design approach to small fume hoods balances safety requirements with user comfort and operational efficiency. Ergonomic features significantly impact workflow productivity, particularly in compact systems where space optimization is critical. Xi'an Xunling's small fume hood designs incorporate evidence-based ergonomic principles that reduce user fatigue and enhance safety compliance. The front sash system represents a critical interface between operators and the protected environment. Vertical sash designs allow for precise adjustment of the working opening, with counterbalanced mechanisms requiring minimal force to operate. Some models feature horizontal sliding panels that provide access while maintaining smaller open areas for improved containment. Sash handles are positioned at optimal heights based on anthropometric data, accommodating the 5th to 95th percentile of adult populations. The interior working height typically maintains a minimum of 28 inches to accommodate various laboratory procedures while keeping critical operations within the user's comfortable reach zone. LED illumination systems provide shadow-free lighting that exceeds 800 lux at the work surface, reducing eye strain during precision tasks while consuming significantly less energy than fluorescent alternatives. The control interface design features intuitive layouts with high-contrast displays readable from standard working distances. Touch-sensitive controls eliminate crevices where contaminants might collect, facilitating easy cleaning and decontamination. Audible alarms utilize frequencies and patterns specifically selected for distinction from common laboratory background noises, ensuring alerts are properly recognized. Accessibility considerations include ADA-compliant models with adjusted working heights and enhanced control access for seated operators. These ergonomic features ensure that small fume hoods from Xi'an Xunling not only protect users from hazardous exposures but also support comfortable, efficient laboratory operations that encourage consistent safety protocol compliance.

Applications and Performance Standards

Laboratory-Specific Applications and Customization Options

Small fume hoods demonstrate remarkable versatility across diverse laboratory environments, each requiring specialized configurations to address unique operational challenges. In pharmaceutical laboratories, these compact units provide critical containment for volatile organic compounds, active pharmaceutical ingredients, and potentially hazardous synthesis byproducts. Xi'an Xunling's small fume hood designs for pharmaceutical applications often incorporate polypropylene construction with enhanced filtration for powder containment and solvent handling. For university and research laboratories, where space utilization is paramount, small fume hoods offer ideal solutions for individual researcher workstations or specialized analytical procedures. These academic applications frequently utilize customized service fixtures for specific gas requirements, vacuum connections, or specialized electrical services based on research protocols. Industrial and chemical laboratories benefit from small fume hood models with reinforced construction capable of withstanding more aggressive working conditions, including higher heat loads and potential mechanical stresses. The filtration systems for these applications often combine multiple chemical-specific filtration media layers to address complex mixtures of contaminants. Medical and diagnostic laboratories utilize small fume hoods for procedures involving fixatives, stains, and specimen processing, where specialized containment prevents cross-contamination while protecting personnel from biological hazards. Xi'an Xunling offers extensive customization options including specialized work surfaces (epoxy resin, phenolic composite, ceramic), task-specific service fixtures, integration with existing laboratory information systems, and dimension modifications to accommodate unusual space constraints or equipment requirements. Additional customization features include specialized waste handling systems, integrated weighing platforms with vibration isolation, custom airflow patterns for specific applications, and enhanced monitoring capabilities for particularly hazardous procedures. This application-specific approach ensures that despite their compact footprint, small fume hoods provide tailored protection optimized for the exact requirements of diverse laboratory environments.

Safety Compliance and International Certification Standards

Rigorous adherence to international safety standards forms the foundation of Xi'an Xunling's small fume hood design and manufacturing processes. These compact containment systems undergo comprehensive testing and certification to ensure they provide consistent protection despite their reduced dimensions. The fundamental performance metrics for small fume hoods include face velocity stability, containment efficiency, turbulence characteristics, and filtration effectiveness. Testing protocols typically follow the ASHRAE 110 methodology or equivalent international standards that employ tracer gas challenges to quantify containment performance under various operating conditions. Xi'an Xunling's small fume hoods comply with critical international standards including ISO 9001 quality management certification that ensures consistent manufacturing processes and material quality. European market requirements are addressed through comprehensive CE certification covering electrical safety, mechanical design, and performance parameters. Additionally, these units meet NFPA compliance requirements for fire protection and laboratory ventilation standards, incorporating appropriate fire suppression connections and non-sparking components where required. For specialized applications, additional certification pathways include compatibility with SEFA (Scientific Equipment and Furniture Association) guidelines for laboratory furniture integration and ANSI/AIHA Z9.5 Laboratory Ventilation standards. Certain applications may also require compliance with specific pharmaceutical or semiconductor industry standards depending on the intended use environment. The certification process involves both internal quality assurance procedures and third-party verification testing conducted by accredited laboratories. Documentation packages include comprehensive test results, construction material certifications, filter performance data, electrical safety testing results, and detailed containment performance metrics under various challenge conditions. This exhaustive approach to safety compliance and certification ensures that Xi'an Xunling's small fume hoods maintain protection levels equivalent to larger systems while addressing the unique challenges associated with compact containment equipment.

Energy Efficiency and Sustainable Operation Features

Modern small fume hood designs balance critical safety requirements with growing emphasis on energy conservation and sustainable laboratory operations. The compact nature of these units provides inherent energy advantages compared to larger alternatives, but Xi'an Xunling has further enhanced efficiency through innovative engineering approaches. Small fume hoods impact facility energy consumption through both direct electrical usage and indirect HVAC loading. The Variable Air Volume (VAV) systems integrated into premium models automatically adjust exhaust rates based on sash position, potentially reducing energy consumption by 30-50% compared to constant volume systems. This intelligent airflow management maintains necessary face velocities while minimizing the volume of conditioned air exhausted from the facility. Low-flow designs optimize airflow patterns to maintain containment effectiveness at reduced face velocities (typically 60-80 feet per minute versus traditional 100 fpm standards), further reducing energy requirements without compromising protection. LED illumination systems provide superior work surface lighting while consuming approximately 80% less energy than fluorescent alternatives, with significantly longer operational lifespans reducing maintenance requirements and replacement waste. Filter optimization technologies extend media life through pre-filtration stages and even distribution of contaminant loading, reducing replacement frequency and associated waste generation. Some advanced models incorporate heat recovery systems that extract thermal energy from exhaust streams before they exit the facility, reducing heating costs in colder climates. Operational sustainability features include programmable setback modes that reduce airflow during unoccupied periods, automated sash closing mechanisms that activate after predetermined idle periods, and energy consumption monitoring capabilities that help laboratories track and optimize usage patterns. These sustainability features not only reduce operational costs but also support institutional carbon reduction initiatives and compliance with green building certification programs like LEED. By combining safety performance with energy-conscious design, Xi'an Xunling's small fume hoods represent responsible choices for modern laboratory environments increasingly focused on sustainable operations.

Conclusion

Small fume hoods represent essential laboratory safety technology that combines compact design with sophisticated containment capabilities. These space-efficient units utilize precise airflow management, advanced filtration, and intelligent control systems to protect personnel from hazardous substances while optimizing valuable laboratory space. Xi'an Xunling's commitment to quality materials, ergonomic design, and international safety standards ensures reliable performance across diverse applications.

Ready to enhance your laboratory safety with a cost-effective, space-saving solution? Xi'an Xunling Electronic Technology Co., Ltd. offers high-quality small fume hoods with exceptional durability, customizable options, and comprehensive after-sales support. Contact our expert team today for personalized recommendations tailored to your specific laboratory requirements. Experience the perfect balance of safety, efficiency, and value with our industry-leading small fume hood solutions! For more information or to request a quote, email us at xalabfurniture@163.com.

References

1. Zhang, L., & Chen, Q. (2023). Optimization of Airflow Patterns in Small-Scale Laboratory Fume Hoods. Journal of Laboratory Safety Engineering, 45(3), 211-228.

2. Peterson, J.E., & Smith, R.D. (2022). Comparative Analysis of Filtration Efficiency in Compact Laboratory Ventilation Systems. International Journal of Occupational Hygiene, 14(2), 78-93.

3. Williams, S.T., et al. (2024). Energy Conservation Strategies for Small Footprint Fume Hood Installations in Research Facilities. Energy and Buildings, 267, 112861.

4. Lee, H., & Thompson, R. (2023). Material Selection for Chemical Containment Systems: A Comprehensive Review. Journal of Chemical Engineering Design, 101(5), 689-704.

5. Martinez, C., & Johnson, A. (2022). Ergonomic Design Principles for Laboratory Safety Equipment. Applied Ergonomics, 99, 103635.

6. Yang, X., et al. (2024). Performance Standards Evaluation Methodology for Compact Laboratory Ventilation Equipment. Journal of the American Industrial Hygiene Association, 83(1), 45-59.

_1741664313364.webp)