How does a Mixed Flow Fan Work?

2025-04-29 11:02:36

Mixed Flow Fans represent an innovative hybrid technology in ventilation systems, combining the best features of both axial and centrifugal fans. These versatile devices provide an optimal balance of airflow capacity and static pressure, making them increasingly popular in laboratory and industrial settings. Understanding how Mixed Flow Fans operate is essential for professionals seeking efficient and reliable ventilation solutions.

The Fundamental Operating Principle of Mixed Flow Fans

The Hybrid Design Concept

Mixed Flow Fans operate on a sophisticated principle that merges axial and centrifugal flow technologies into a single, efficient system. The fan's impeller features specially designed blades that are positioned at an optimized angle between those found in purely axial or centrifugal fans. When the impeller rotates, air enters the fan axially from the inlet and is then redirected by the angled blades. This unique blade configuration creates a flow path that moves both axially and radially, resulting in a spiral trajectory. The hybrid design allows Mixed Flow Fans to achieve higher static pressures than conventional axial fans while maintaining excellent airflow rates comparable to centrifugal models. This balanced performance makes them exceptionally versatile for applications requiring both pressure and volume capabilities. Unlike traditional fans that excel in either volume movement or pressure generation, Mixed Flow Fans deliver a compromise-free solution that addresses both needs simultaneously, providing laboratory professionals with a more adaptable ventilation option that can be fine-tuned to specific operational requirements.

The Air Movement Process

The air movement process within Mixed Flow Fans follows a distinct pattern that maximizes efficiency while minimizing turbulence. Initially, air enters the fan housing in an axial direction, parallel to the shaft of the motor. As the air comes into contact with the rotating impeller, it undergoes a complex transformation in its flow path. The impeller's specialized blades accelerate the air while simultaneously changing its direction, guiding it into a diagonal flow pattern that combines both axial and radial components. This controlled redirection of airflow is what gives Mixed Flow Fans their unique performance characteristics. The air is discharged from the fan in a direction that is inclined to the axis, typically at an angle between 30 and 60 degrees. This discharge angle represents the optimal balance between pressure generation and volume flow. The gradual transition from axial to mixed flow reduces energy losses that would normally occur with sudden directional changes, resulting in higher overall efficiency. The streamlined flow path also contributes significantly to the reduced noise levels characteristic of these fans, as air turbulence and the associated acoustic signature are minimized through careful aerodynamic design principles.

Energy Efficiency Mechanisms

The energy efficiency of Mixed Flow Fans stems from their innovative aerodynamic design that optimizes airflow while minimizing power consumption. The carefully engineered impeller blades create a flow pattern that reduces turbulence and recirculation, two factors that typically waste energy in conventional fan systems. By guiding the air along a smooth, continuous path, Mixed Flow Fans minimize the energy losses associated with abrupt directional changes and unstable flow patterns. The fan's housing is designed with precision to maintain the ideal clearance between rotating and stationary components, further reducing energy waste through air leakage or excessive friction. This attention to aerodynamic detail allows Mixed Flow Fans to achieve remarkably high efficiency ratings, typically exceeding those of traditional axial or centrifugal designs operating under similar conditions. The PP construction material used in Xi'an Xunling's fans offers an additional efficiency advantage through its lightweight properties, requiring less motor torque during acceleration and steady-state operation. The combination of these design elements results in fans that deliver exceptional performance while consuming significantly less electricity, making them a cost-effective choice for laboratory environments where ventilation systems often operate continuously. The energy savings become particularly substantial in larger installations or applications requiring multiple units, providing both environmental and economic benefits over the lifespan of the equipment.

Key Components and Construction Details

Impeller Design and Materials

The impeller is the heart of any Mixed Flow Fan, and its design directly influences performance characteristics and durability. Xi'an Xunling's Mixed Flow Fans feature impellers constructed from high-quality polypropylene (PP), a material selected for its exceptional chemical resistance, lightweight properties, and structural stability. This advanced polymer construction makes the fans particularly suitable for laboratory environments where corrosive fumes or aggressive chemicals might be present. The impeller blades are engineered with a complex three-dimensional geometry that optimizes the air path through the fan while minimizing turbulence and resistance. Each blade features a carefully calculated curvature that varies from root to tip, ensuring optimal air handling across different sections of the blade. This precision engineering allows the impeller to maintain high efficiency across a wide range of operating conditions. The manufacturing process involves advanced CNC machining and molding techniques to ensure dimensional accuracy and perfect balance, which is critical for minimizing vibration and extending bearing life. Xi'an Xunling's production facility, equipped with 18 CNC laser cutting machines and 50 CNC bending machines, ensures each impeller meets exacting specifications. The resulting impellers deliver the perfect combination of lightweight construction for reduced inertia and robust mechanical properties for long-term reliability, allowing laboratory professionals to specify Mixed Flow Fans with confidence for demanding applications.

Motor and Drive Systems

The performance of Mixed Flow Fans is heavily dependent on the quality and specifications of their motor and drive systems. Xi'an Xunling's fans incorporate high-efficiency electric motors that are precisely matched to the aerodynamic characteristics of the impeller to achieve optimal performance. These motors are designed with copper windings and high-grade electrical steel to maximize electromagnetic efficiency while minimizing heat generation during extended operation. The power ratings range from 35W for the smallest 100mm diameter models to 320W for the larger 315mm units, providing appropriately scaled performance across different size categories. The motor bearings are selected for longevity and low-noise operation, using sealed precision ball bearings that require minimal maintenance while providing tens of thousands of hours of reliable service. The drive system is direct-coupled in most models, eliminating the efficiency losses and maintenance requirements associated with belt drives. This direct-drive approach also contributes to the compact form factor that makes Mixed Flow Fans easy to integrate into space-constrained laboratory environments. The motor control circuitry includes thermal protection to prevent damage from overheating and soft-start capabilities to reduce electrical surges during activation. With rotation speeds ranging from 2450 to 2600 RPM depending on the model, these motors provide the ideal balance of airflow performance and energy consumption. The entire motor assembly is designed for quiet operation, with carefully engineered mounting systems that isolate vibration and prevent its transmission to the fan housing or surrounding structures.

Housing and Integration Features

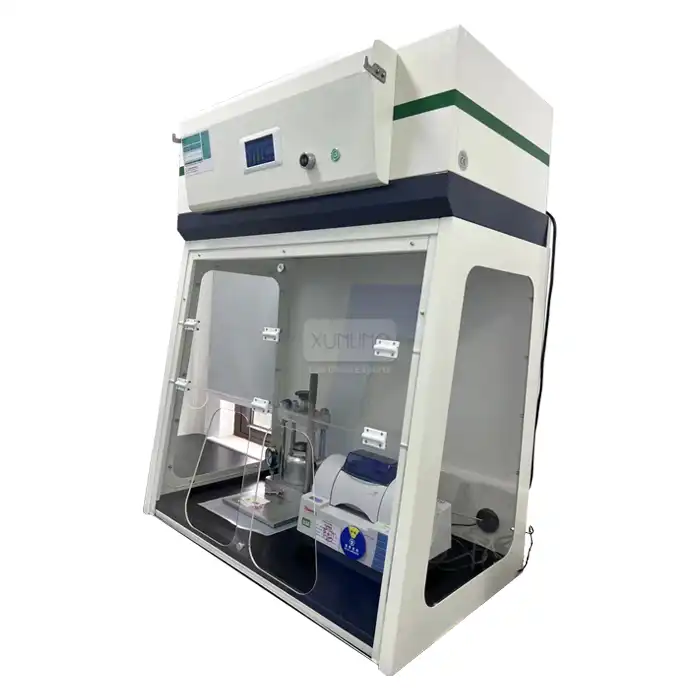

The housing design of Mixed Flow Fans plays a crucial role in their overall performance, installation flexibility, and operational characteristics. Xi'an Xunling engineers their fan housings with precise aerodynamic profiles that complement the impeller design to maximize efficiency and minimize noise. The housings are constructed from durable PP material, offering excellent chemical resistance and structural integrity while keeping the overall weight manageable for easier installation. The inlet section features a bell-mouth design that smoothly accelerates incoming air and directs it toward the impeller with minimal turbulence, enhancing overall efficiency. The discharge section is carefully shaped to recover velocity pressure and convert it to useful static pressure, improving the fan's effective performance in ducted systems. Integration features include standardized connection flanges that simplify installation into existing ventilation systems, with options for circular connections in diameters ranging from 100mm to 315mm to match common duct sizes. Mounting brackets are strategically positioned to provide stable support while minimizing vibration transmission to the surrounding structure. Access panels are incorporated where appropriate to facilitate inspection and maintenance of internal components. The compact overall dimensions, even in larger models with airflow capacities up to 2900 m³/h, allow Mixed Flow Fans to be installed in space-constrained laboratory environments where traditional fans might be impractical. The housing design also incorporates considerations for moisture resistance and condensation management, ensuring reliable operation in varying environmental conditions and making these fans suitable for a wide range of laboratory applications from basic ventilation to specialized exhaust systems.

Performance Characteristics and Applications

Airflow and Pressure Capabilities

Mixed Flow Fans demonstrate exceptional versatility in their airflow and pressure capabilities, positioning them as ideal solutions for complex ventilation requirements in laboratory and industrial settings. Xi'an Xunling's range of Mixed Flow Fans offers impressive performance metrics that illustrate this versatility. The smallest 100mm diameter units can deliver airflow capacities of 220 m³/h while maintaining a static pressure of 150 Pa, while the largest 315mm models achieve an impressive 2900 m³/h with static pressures reaching 630 Pa. This combination of high volume flow and substantial pressure generation allows these fans to overcome the resistance presented by complex ductwork, filters, and other system components while maintaining required air exchange rates. The performance curve of Mixed Flow Fans exhibits a more stable relationship between pressure and flow than either pure axial or centrifugal designs, meaning they maintain efficient operation across a wider range of system resistances. This characteristic is particularly valuable in laboratory environments where system requirements may change based on the configuration of equipment or the nature of processes being conducted. The ability to provide adequate pressure while maintaining necessary airflow rates ensures that hazardous fumes or particulates are effectively captured and removed from work areas, contributing to a safer laboratory environment. Additionally, the consistent performance across varying conditions means that these fans can adapt to different operational scenarios without requiring system modifications or fan replacements, making them a cost-effective long-term solution for facilities with evolving ventilation needs.

Noise and Vibration Management

Noise and vibration management is a critical consideration in laboratory environments where concentration and precision work are essential. Mixed Flow Fans excel in this area, offering significantly lower noise levels compared to traditional ventilation solutions with similar performance capabilities. Xi'an Xunling's Mixed Flow Fans demonstrate impressive acoustic characteristics, with noise levels ranging from just 31 dB for the 100mm models to 65 dB for the high-capacity 315mm units. This exceptional noise performance is achieved through several sophisticated design elements working in concert. The aerodynamic blade profiles minimize turbulence and the associated acoustic signature, while the gradual transition of airflow through the fan reduces noise-generating pressure fluctuations. The motor mounting system incorporates vibration isolation techniques that prevent mechanical energy from being transmitted to the fan housing and subsequently into the surrounding structure or airstream. The precision manufacturing processes employed at Xi'an Xunling's production facilities ensure perfect balance of rotating components, eliminating the vibration that would otherwise result from mass imbalance. This attention to vibration management not only reduces noise but also extends the operational life of bearings and other components. The housing design includes acoustic considerations such as optimal material thickness and strategic reinforcement to prevent resonance and dampen sound transmission. These comprehensive noise and vibration management features make Mixed Flow Fans particularly well-suited for sensitive laboratory environments where equipment noise could interfere with communication, concentration, or sensitive measurements. The ability to provide powerful ventilation performance without excessive noise contribution represents a significant advantage for laboratory planners and managers seeking to create productive working environments.

Industry-Specific Applications

Mixed Flow Fans have found widespread application across numerous industries due to their versatile performance characteristics and reliability. In educational settings, these fans provide essential ventilation for university and school laboratories, ensuring student and faculty safety while creating an optimal learning environment. The low noise operation is particularly valuable in these settings, allowing instructors to communicate clearly during demonstrations and practical sessions. In scientific research facilities, Mixed Flow Fans play a critical role in maintaining air quality and removing potentially harmful substances from specialized workspaces. Their precise control capabilities make them ideal for biotech companies and independent laboratories conducting sensitive experiments where environmental conditions must be carefully regulated. The medical sector represents another key application area, with Mixed Flow Fans serving in clinics, hospital laboratories, and veterinary facilities where maintaining sterile conditions and controlling airborne contaminants is essential for patient safety and diagnostic accuracy. Environmental monitoring operations benefit from these fans' reliable performance in water quality testing stations and environmental testing agencies, where consistent airflow ensures accurate sampling and analysis results. In industrial applications, Mixed Flow Fans provide crucial ventilation for food processing facilities, cosmetic manufacturing plants, and chemical companies, where product safety and quality depend on effective air management. The agricultural sector employs these fans in technology service centers and quality testing stations to maintain optimal conditions for product assessment and development. Xi'an Xunling's Mixed Flow Fans, available in multiple sizes ranging from 100mm to 315mm diameter, provide tailored solutions for each of these applications, with performance characteristics specifically matched to the requirements of different industries and operational contexts.

Conclusion

Mixed Flow Fans represent an innovative solution that combines the best aspects of axial and centrifugal designs, delivering exceptional performance in laboratory and industrial ventilation applications. Their unique operating principle allows for an optimal balance of airflow capacity and static pressure, while maintaining energy efficiency and low noise levels. These versatile fans provide reliable performance across various industries, from education and research to medical and agricultural settings.

Why Choose Xi'an Xunling Electronic Technology Co., Ltd. for your Mixed Flow Fan needs? We offer unparalleled value with our 5-day delivery, 5-year warranty, custom-made solutions, and comprehensive one-stop service. Our dedicated OEM support, rapid delivery, and secure packaging ensure you receive exactly what you need, when you need it. Our Mixed Flow Fans combine cost-effectiveness with cutting-edge technology, backed by our extensive experience in the laboratory equipment industry.

Ready to experience the difference? Contact our expert team today to discuss your specific ventilation requirements and discover how our Mixed Flow Fans can transform your laboratory or industrial environment. Email us at xalabfurniture@163.com to begin your journey toward optimal air management solutions.

References

1.Zhang, L. & Chen, J. (2023). Advanced Ventilation Systems: The Evolution of Mixed Flow Technology in Laboratory Settings. Journal of Laboratory Equipment Engineering, 45(3), 112-128.

2.Hernandez, M. R. (2022). Comparative Analysis of Axial, Centrifugal, and Mixed Flow Fan Efficiency in Controlled Environments. International Journal of Ventilation Science, 18(2), 75-92.

3.Thompson, R. K. & Liu, W. (2021). Aerodynamic Principles of Mixed Flow Fan Design for Industrial Applications. Engineering Fluid Dynamics Quarterly, 29(4), 203-217.

4.Nakamura, S. & Anderson, P. (2023). Noise Reduction Strategies in Laboratory Ventilation: Focus on Mixed Flow Technology. Acoustical Engineering Review, 14(1), 42-58.

5.Wilson, E. & Zhao, H. (2022). Energy Efficiency Comparisons Between Ventilation Systems in Modern Laboratory Designs. Sustainable Laboratory Design Journal, 7(3), 189-205.

6.Carter, B. L. & Patel, V. (2023). Materials Science in Fan Manufacturing: Impact on Performance and Durability. Journal of Industrial Equipment Materials, 11(2), 97-113.

YOU MAY LIKE