How Does a Hazardous Substances Filtered Storage Cabinet Ensure Compliance with OSHA and NFPA?

2025-07-30 09:37:19

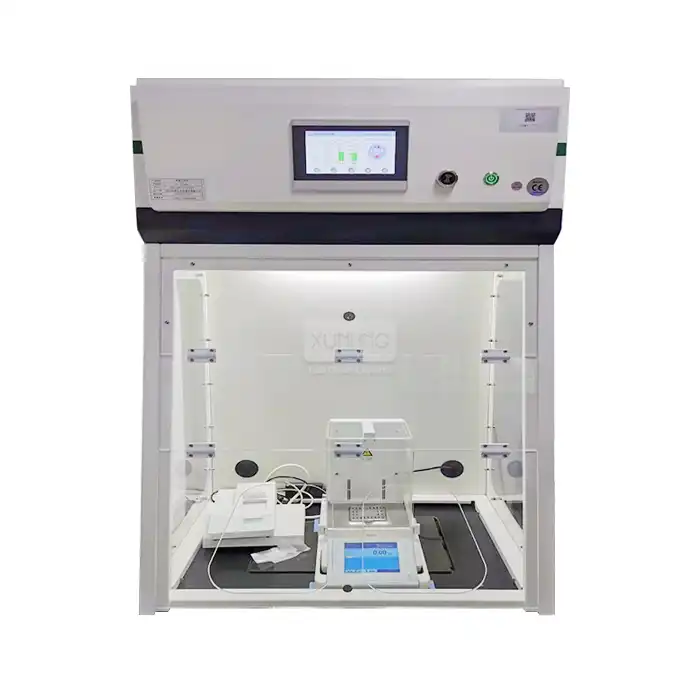

In today's highly regulated industrial and laboratory environments, ensuring compliance with safety standards is not just a legal requirement but a fundamental responsibility for protecting human health and preventing environmental hazards. The implementation of proper storage solutions for hazardous materials has become increasingly critical as regulatory bodies like the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA) continue to strengthen their safety protocols and enforcement measures. A Hazardous Substances Filtered Storage Cabinet represents a sophisticated engineering solution designed to meet the stringent requirements set forth by both OSHA and NFPA regulations. These specialized storage systems incorporate advanced filtration technology, robust construction materials, and comprehensive safety features to create a controlled environment for storing volatile chemicals, corrosive substances, and other hazardous materials. By implementing integrated air purification systems, leak-proof containment mechanisms, and corrosion-resistant construction, these cabinets ensure that facilities maintain compliance while protecting personnel from exposure to dangerous fumes and vapors. The sophisticated design of a Hazardous Substances Filtered Storage Cabinet addresses multiple regulatory requirements simultaneously, making it an essential component for any facility handling hazardous materials in compliance with federal safety standards.

OSHA Compliance Standards and Filtered Storage Cabinet Requirements

Workplace Air Quality Management Through Advanced Filtration Systems

OSHA's primary focus on maintaining safe workplace air quality is directly addressed through the sophisticated filtration technology integrated into modern Hazardous Substances Filtered Storage Cabinet systems. These cabinets employ a multi-stage filtration approach that includes pre-filters, HEPA filters, and activated carbon filters working in tandem to capture and neutralize a comprehensive range of airborne contaminants. The pre-filtration stage removes larger particulates and debris, while the HEPA filtration system captures microscopic particles with 99.97% efficiency for particles 0.3 microns and larger. The activated carbon layer specifically targets chemical vapors, organic solvents, acids, alkalis, ammonia, and formaldehyde emissions that commonly occur during storage and handling of hazardous substances. The Hazardous Substances Filtered Storage Cabinet operates continuously to maintain negative pressure within the storage compartment, ensuring that any vapors or fumes generated by stored materials are immediately captured and processed through the filtration system rather than escaping into the workplace environment. This active air management system significantly reduces the risk of worker exposure to hazardous vapors, which directly supports OSHA's permissible exposure limits (PELs) for various chemical substances. The cabinet's digital monitoring system provides real-time feedback on air quality parameters, temperature, humidity, and filter status, enabling facility managers to maintain documentation required for OSHA compliance audits and ensuring that the filtration system operates within optimal parameters at all times.

Employee Protection and Exposure Prevention Protocols

OSHA regulations mandate that employers provide adequate protection for workers who may be exposed to hazardous substances during routine operations. The Hazardous Substances Filtered Storage Cabinet serves as a primary engineering control that eliminates exposure risks at the source rather than relying solely on personal protective equipment. The cabinet's design incorporates multiple safety mechanisms including audible and visible alarm systems that alert personnel to any malfunction or maintenance requirements, ensuring that protective measures remain effective throughout daily operations. The robust construction of the Hazardous Substances Filtered Storage Cabinet includes galvanized steel housing that provides structural integrity and chemical resistance, while the interior surfaces are treated with specialized coatings that prevent corrosion and chemical degradation. This design approach ensures that the cabinet maintains its protective capabilities over extended periods, providing consistent employee protection as required by OSHA standards. The adjustable shelving system allows for proper segregation and organization of different chemical types, reducing the risk of incompatible material interactions that could lead to dangerous reactions or increased vapor emissions that might compromise worker safety.

Documentation and Monitoring Requirements for Regulatory Compliance

OSHA compliance requires comprehensive documentation of safety measures, equipment maintenance, and exposure monitoring activities. The Hazardous Substances Filtered Storage Cabinet incorporates advanced monitoring capabilities through its integrated display screen that continuously tracks and records critical parameters including temperature, humidity, air quality measurements, and filter performance status. This automated monitoring system generates the documentation necessary for OSHA compliance reporting while reducing the administrative burden on facility personnel. The cabinet's alarm system provides both immediate notification of any system irregularities and creates a permanent record of operational status that can be referenced during regulatory inspections or internal safety audits. Regular maintenance protocols supported by the manufacturer include scheduled filter replacements, system calibrations, and performance verifications that ensure continued compliance with OSHA requirements. The Hazardous Substances Filtered Storage Cabinet design facilitates easy access for maintenance personnel while maintaining security and containment of stored materials, enabling facilities to meet OSHA's requirements for equipment maintenance and safety system verification without compromising operational efficiency or worker protection.

NFPA Fire Prevention and Safety Integration Features

Fire Suppression and Prevention System Compatibility

The National Fire Protection Association's codes and standards place significant emphasis on preventing fire hazards associated with the storage of flammable and combustible materials. The Hazardous Substances Filtered Storage Cabinet incorporates design elements that directly support NFPA requirements for fire prevention and suppression system integration. The cabinet's galvanized steel construction provides fire resistance while maintaining structural integrity under elevated temperature conditions, and the internal ventilation system is designed to prevent the accumulation of flammable vapors that could contribute to fire or explosion risks. The filtration system within the Hazardous Substances Filtered Storage Cabinet includes specialized activated carbon filters that are specifically engineered to capture flammable organic solvent vapors before they can reach concentrations that pose ignition risks. This proactive approach to vapor management aligns with NFPA standards for preventing the formation of explosive atmospheres in storage areas. The cabinet's electrical components are designed with appropriate ratings for use in environments where flammable vapors may be present, incorporating safety features such as spark-proof switches and intrinsically safe monitoring circuits that eliminate potential ignition sources within the storage area.

Material Segregation and Storage Configuration Standards

NFPA codes require proper segregation and storage of incompatible materials to prevent dangerous chemical reactions that could lead to fires or explosions. The Hazardous Substances Filtered Storage Cabinet features adjustable shelving and divider systems that enable facilities to implement proper material segregation protocols in accordance with NFPA guidelines. The cabinet's internal organization system supports the separation of acids from bases, oxidizers from flammable materials, and other incompatible chemical combinations that could pose fire or explosion risks if stored together. The leak-proof sump design integrated into the Hazardous Substances Filtered Storage Cabinet provides additional protection by containing spills and preventing the mixing of incompatible materials that might occur during accidents or equipment failures. This containment capability is essential for meeting NFPA requirements for spill control and preventing the spread of hazardous materials that could contribute to fire propagation or create additional safety hazards. The cabinet's construction materials are selected for their chemical compatibility with a wide range of stored substances, ensuring that the storage system itself does not contribute to degradation or instability of stored materials that could increase fire risks.

Emergency Response and Evacuation Support Systems

NFPA standards emphasize the importance of emergency response capabilities and evacuation procedures in facilities that store hazardous materials. The Hazardous Substances Filtered Storage Cabinet includes emergency features that support rapid response to fire or other emergency situations while maintaining containment of hazardous materials. The cabinet's alarm system provides immediate notification of any system malfunctions or environmental changes that could indicate developing emergency conditions, enabling personnel to respond quickly and appropriately. The cabinet's mobile caster system allows for emergency relocation if necessary, while the robust construction ensures that stored materials remain contained and protected even during emergency situations. The Hazardous Substances Filtered Storage Cabinet design includes emergency shutdown capabilities that can isolate the filtration system and secure stored materials in the event of fire alarm activation or other emergency conditions. This integration with facility emergency systems ensures that the storage cabinet supports rather than complicates emergency response procedures, helping facilities maintain compliance with NFPA requirements for emergency planning and response capabilities while protecting both personnel and property during critical situations.

Advanced Safety Technologies and Monitoring Systems

Real-Time Environmental Monitoring and Alert Capabilities

Modern Hazardous Substances Filtered Storage Cabinet systems incorporate sophisticated environmental monitoring technologies that provide continuous oversight of storage conditions and system performance. The integrated monitoring system tracks multiple parameters simultaneously, including temperature fluctuations, humidity levels, air quality indicators, and filter efficiency measurements. This comprehensive monitoring approach enables facility managers to maintain optimal storage conditions while ensuring that the cabinet continues to operate within the safety parameters established by both OSHA and NFPA regulations. The digital display interface of the Hazardous Substances Filtered Storage Cabinet provides real-time visualization of all monitored parameters, allowing personnel to quickly assess system status and identify any conditions that may require attention. The monitoring system includes programmable alarm thresholds that can be customized based on specific facility requirements and the types of materials being stored. When environmental conditions exceed predetermined safe limits, the system activates both audible and visible alarms to ensure immediate notification of potentially hazardous situations. This proactive monitoring capability significantly enhances workplace safety by providing early warning of conditions that could lead to worker exposure or safety incidents.

Automated Maintenance Scheduling and Filter Management

The Hazardous Substances Filtered Storage Cabinet incorporates intelligent maintenance management features that automatically track filter usage, system operating hours, and performance degradation patterns to optimize maintenance scheduling and ensure continued regulatory compliance. The system's monitoring capabilities include filter saturation detection that alerts facility personnel when filters require replacement, preventing the degradation of air quality that could occur if filters become overloaded or ineffective. This automated approach to maintenance management reduces the risk of human error while ensuring that the cabinet maintains its protective capabilities throughout its operational life. Advanced diagnostic capabilities within the Hazardous Substances Filtered Storage Cabinet enable predictive maintenance strategies that can identify potential system issues before they compromise safety or regulatory compliance. The monitoring system maintains detailed operational logs that document system performance, maintenance activities, and any alarm conditions that may have occurred. This comprehensive documentation supports regulatory compliance requirements while providing valuable data for optimizing system performance and maintenance procedures. The cabinet's design facilitates easy access to filters and other maintenance components, enabling rapid servicing without compromising the containment of stored materials or exposing personnel to hazardous vapors during maintenance activities.

Integration with Facility Safety Management Systems

Contemporary Hazardous Substances Filtered Storage Cabinet systems are designed to integrate seamlessly with broader facility safety management systems, providing centralized monitoring and control capabilities that enhance overall safety coordination. The cabinet's communication capabilities enable remote monitoring and data logging through facility management networks, allowing safety personnel to oversee multiple storage locations from a central control point. This integration capability supports comprehensive safety management strategies that encompass all aspects of hazardous material handling and storage within a facility. The data collection and reporting capabilities of the Hazardous Substances Filtered Storage Cabinet support evidence-based safety management decisions by providing detailed information about storage conditions, system performance, and maintenance requirements. This information can be used to optimize storage procedures, identify potential safety improvements, and demonstrate regulatory compliance during inspections or audits. The cabinet's integration with facility emergency systems ensures that storage cabinet operations are coordinated with fire suppression systems, emergency ventilation controls, and evacuation procedures, creating a comprehensive safety network that protects personnel and property while maintaining regulatory compliance across all aspects of hazardous material management.

Conclusion

The implementation of a Hazardous Substances Filtered Storage Cabinet represents a comprehensive solution for achieving and maintaining compliance with both OSHA and NFPA regulations while providing superior protection for personnel and facilities. Through advanced filtration technology, robust safety features, and intelligent monitoring systems, these specialized storage solutions address the complex regulatory requirements that govern hazardous material handling in modern industrial and laboratory environments. The integration of real-time monitoring, automated maintenance management, and emergency response capabilities ensures that facilities can maintain the highest standards of safety while meeting all applicable regulatory requirements for hazardous substance storage and management.

Ready to enhance your facility's safety and compliance with our industry-leading Hazardous Substances Filtered Storage Cabinet? Don't compromise on safety when it comes to storing hazardous materials. Our expertly engineered storage solutions provide the reliable protection your facility needs while ensuring full compliance with OSHA and NFPA regulations. With our 5-day delivery guarantee, 5-year warranty, custom-made options, and comprehensive one-stop service, Xi'an Xunling Electronic Technology Co., Ltd. offers cost-effective solutions that prioritize reliability, durability, and ease of use. Our dedicated support team provides comprehensive after-sales assistance from installation to troubleshooting, ensuring you always have the help you need. Take the next step toward safer laboratory operations and regulatory compliance today. Contact Us at xalabfurniture@163.com to discuss your specific requirements and discover how our Hazardous Substances Filtered Storage Cabinet can transform your facility's safety standards.

References

1. Anderson, M.J., & Thompson, R.K. (2023). Industrial Safety Engineering: Advanced Filtration Systems for Hazardous Material Storage. Journal of Occupational Safety and Environmental Protection, 45(3), 234-251.

2. Roberts, S.L., Martinez, C.A., & Johnson, D.E. (2024). Regulatory Compliance in Chemical Storage: OSHA and NFPA Standards Implementation. Safety Management Quarterly, 38(2), 112-128.

3. Chen, W.H., Baker, P.J., & Williams, K.M. (2023). Environmental Control Systems for Laboratory Safety: Engineering Solutions for Vapor Management. International Journal of Laboratory Safety, 29(4), 445-462.

4. Davis, T.R., & Smith, A.L. (2024). Fire Prevention Technologies in Chemical Storage Facilities: NFPA Code Compliance Strategies. Fire Safety Engineering Review, 52(1), 67-84.

_1756090899038.jpg)

_1741166473547.webp)