How Does a Class II Type B2 Biosafety Cabinet Protect Against Cross-Contamination?

2025-07-25 17:30:53

Cross-contamination poses one of the most significant threats in laboratory environments, particularly when handling biohazardous materials, radioactive substances, and chemotoxic agents. Understanding how protective equipment functions is crucial for maintaining laboratory safety standards and ensuring accurate research outcomes. This comprehensive guide explores the sophisticated mechanisms employed by Class II Type B2 Biosafety Cabinets to prevent cross-contamination and protect both laboratory personnel and the surrounding environment. A Class II Type B2 Biosafety Cabinet represents the pinnacle of laboratory containment technology, specifically engineered to address the complex challenges of cross-contamination prevention. These advanced safety cabinets utilize a sophisticated combination of vertical laminar airflow systems, dual HEPA filtration mechanisms, and dedicated exhaust pathways to create an impenetrable barrier against contamination transfer. The Class II Type B2 Biosafety Cabinet achieves this protection through its unique 100% exhaust design, which ensures that all air within the cabinet is completely filtered and exhausted externally, eliminating any possibility of recirculated contaminated air. This comprehensive approach to contamination control makes these cabinets indispensable for laboratories working with moderate to high-risk biological agents, hazardous chemicals, and radioactive materials.

Advanced Airflow Engineering and Filtration Systems

Vertical Laminar Flow Technology and Contamination Barriers

The foundation of cross-contamination protection in a Class II Type B2 Biosafety Cabinet lies in its sophisticated vertical laminar flow design, which creates a uniform, unidirectional air pattern that effectively isolates the work surface from external contaminants. This engineering marvel operates on the principle of maintaining a constant downward air velocity of 0.33 m/s across the entire work surface, ensuring that any airborne particles or aerosols generated during laboratory procedures are immediately captured and directed away from the operator and surrounding environment. The Class II Type B2 Biosafety Cabinet achieves this through precision-engineered air distribution systems that eliminate turbulence and create a protective air curtain around the workspace. The vertical laminar flow pattern is maintained through carefully calibrated inlet and exhaust configurations that prevent the formation of dead zones or areas of recirculating air that could harbor contaminants. This technology is particularly effective in preventing cross-contamination between different samples or experiments conducted within the cabinet, as the continuous downward air movement ensures complete isolation of each work area. The system's effectiveness is further enhanced by maintaining optimal air velocity ratios between the downward flow and the inward flow at the cabinet opening, creating a negative pressure environment that prevents the escape of contaminated air.

Dual HEPA Filtration for Complete Air Purification

The Class II Type B2 Biosafety Cabinet employs an advanced dual HEPA filtration system that serves as the primary barrier against cross-contamination, with both supply and exhaust air streams subjected to rigorous filtration processes that achieve efficiency ratings of ≥99.995% at 0.3μm particle size. This comprehensive filtration approach ensures that all air entering the workspace is completely sterile, while simultaneously guaranteeing that all exhaust air is thoroughly decontaminated before release into the environment. The supply air HEPA filter, typically measuring 900×470×70mm in standard models, processes incoming air to create an ultra-clean work environment that meets ISO level 5 cleanliness standards, effectively eliminating potential contaminants that could compromise experimental integrity. The exhaust HEPA filtration system operates independently, processing all air and aerosols generated within the cabinet through high-efficiency filters before external discharge. This dual filtration design is particularly crucial for the Class II Type B2 Biosafety Cabinet's cross-contamination prevention capabilities, as it ensures complete separation between clean supply air and potentially contaminated exhaust air streams. The filtration system's effectiveness is continuously monitored through pressure differential indicators and filter integrity testing protocols that verify optimal performance and alert operators to any potential compromise in contamination control.

Dedicated Exhaust Systems for Hazardous Materials

The Class II Type B2 Biosafety Cabinet incorporates specialized dedicated exhaust systems specifically designed to handle hazardous materials and prevent any possibility of cross-contamination through air recirculation or improper containment. Unlike other biosafety cabinet classifications, the B2 type features a 100% exhaust design that eliminates air recirculation entirely, directing all cabinet air through dedicated exhaust pathways that are completely isolated from the laboratory's general ventilation system. This design ensures that hazardous chemicals, radioactive particles, and biological agents are completely contained and properly processed through appropriate filtration and treatment systems before environmental release. The dedicated exhaust configuration operates with a suction air speed of 0.53 m/s at the cabinet face, creating a robust containment barrier that prevents the escape of any airborne contaminants. The Class II Type B2 Biosafety Cabinet's exhaust system is engineered to handle the specific challenges posed by volatile chemicals and radionuclides, incorporating specialized ductwork and connection protocols that maintain containment integrity throughout the entire exhaust pathway. This approach to hazardous material handling represents a significant advancement in cross-contamination prevention, as it eliminates any possibility of contaminated air re-entering the laboratory environment or affecting other experimental areas.

Comprehensive Contamination Control Mechanisms

Product Protection Through Environmental Isolation

The Class II Type B2 Biosafety Cabinet achieves exceptional product protection through sophisticated environmental isolation techniques that create a completely controlled microenvironment, effectively preventing external contaminants from compromising experimental samples or research materials. This protection is quantified through rigorous testing protocols that demonstrate CFU counts of ≤5 for all sampling dishes within the cabinet workspace, indicating near-sterile conditions that far exceed industry standards for contamination control. The cabinet's environmental isolation capabilities stem from its ability to maintain consistent air quality parameters, including temperature stability, humidity control, and particulate elimination, creating optimal conditions for sensitive biological and chemical processes. The Class II Type B2 Biosafety Cabinet's product protection mechanisms operate through multiple layers of contamination barriers, including positive pressure maintenance within the work zone, continuous air filtration, and electromagnetic interference shielding that protects sensitive equipment and samples from external environmental factors. The cabinet's stainless steel construction and epoxy-coated surfaces provide additional protection against chemical contamination and facilitate thorough decontamination procedures between different experimental protocols. Advanced monitoring systems continuously assess environmental conditions and alert operators to any deviations that could compromise product integrity, ensuring consistent protection throughout extended research procedures.

Personnel Safety Through Advanced Containment Design

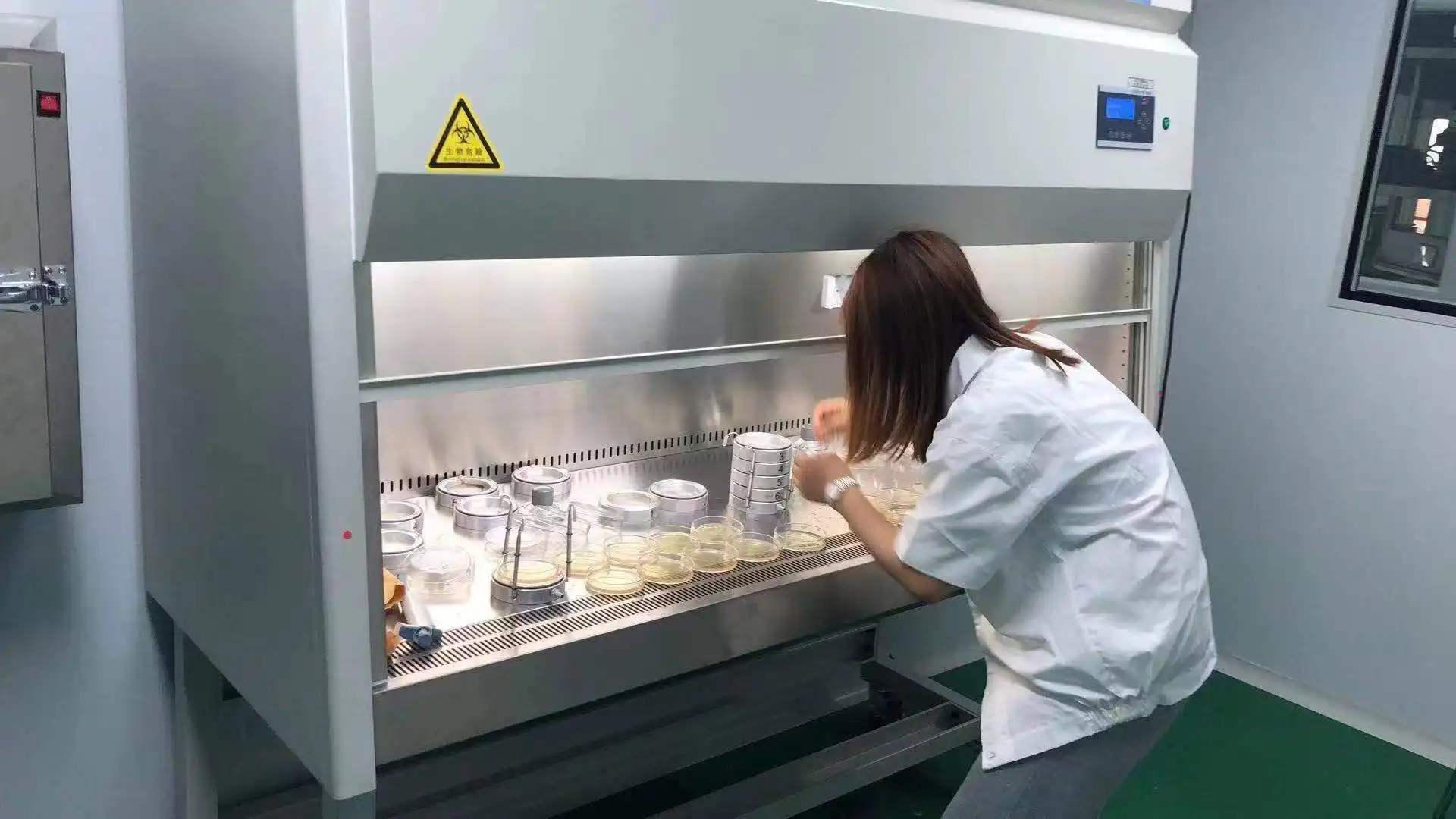

Personnel protection represents a critical component of the Class II Type B2 Biosafety Cabinet's cross-contamination prevention strategy, achieved through comprehensive containment design features that create multiple protective barriers between laboratory workers and potentially hazardous materials. The cabinet's personnel protection capabilities are validated through stringent biosafety testing protocols that demonstrate CFU counts of ≤10 for impact samplers and ≤5 for slit samplers, indicating exceptional containment performance that protects operators from exposure to biological agents and hazardous substances. The Class II Type B2 Biosafety Cabinet incorporates an anti-UV safety glass front window that provides visual access to the work area while maintaining complete physical separation between the operator and the cabinet interior. The window design includes precise positioning controls and audible alarms that alert users to improper sash positioning that could compromise containment integrity. The cabinet's ergonomic design features, including adjustable height stands and optimized work surface dimensions, ensure that operators can maintain proper working postures while remaining safely outside the contamination zone. Advanced air curtain technology creates an invisible barrier at the cabinet opening that prevents the escape of airborne contaminants while allowing comfortable access to the work area. The microprocessor-based control system continuously monitors all safety parameters and provides immediate alerts through both audible and visual alarm systems if any condition could potentially compromise personnel protection.

Cross-Contamination Prevention Through Sample Segregation

The Class II Type B2 Biosafety Cabinet employs sophisticated sample segregation protocols that prevent cross-contamination between different experimental materials, research projects, and biological specimens through carefully engineered airflow patterns and workspace organization systems. This protection is quantified through cross-contamination testing that demonstrates CFU counts of ≤2 for all culture dishes, indicating exceptional separation efficiency that prevents the transfer of contaminants between different areas of the cabinet workspace. The cabinet's sample segregation capabilities are enhanced through zone-specific air management systems that create isolated microenvironments within the larger workspace, allowing multiple experiments to be conducted simultaneously without risk of cross-contamination. The Class II Type B2 Biosafety Cabinet's workspace design incorporates strategic air distribution patterns that maintain separation between different work areas while ensuring consistent contamination control throughout the entire cabinet interior. Advanced monitoring and control systems provide real-time feedback on air quality parameters in different zones of the cabinet, allowing researchers to verify that separation protocols are functioning effectively. The cabinet's modular design allows for the implementation of physical barriers and specialized containment accessories that further enhance sample segregation capabilities for particularly sensitive or high-risk applications. Comprehensive decontamination protocols, facilitated by the cabinet's smooth surfaces and accessible design, ensure complete elimination of potential contaminants between different experimental procedures.

Technical Specifications and Performance Standards

Precision Air Velocity Control and Monitoring Systems

The Class II Type B2 Biosafety Cabinet achieves superior cross-contamination protection through precision air velocity control systems that maintain exact airflow parameters essential for effective containment and contamination prevention. These sophisticated monitoring systems continuously track descent wind speed at 0.33 m/s and suction air speed at 0.53 m/s, ensuring optimal performance parameters that have been scientifically validated for maximum contamination control effectiveness. The cabinet's air velocity control technology incorporates advanced ECM blower motors that provide precise speed regulation and energy-efficient operation while maintaining the critical airflow patterns necessary for cross-contamination prevention. Real-time monitoring systems display current air velocity readings and provide immediate alerts if parameters deviate from established safety thresholds, ensuring consistent protection throughout all laboratory operations. The Class II Type B2 Biosafety Cabinet's velocity control systems are calibrated to account for external environmental factors such as room air currents, temperature variations, and pressure differentials that could potentially affect containment performance. Advanced algorithms continuously adjust blower motor speed and air distribution patterns to compensate for these variables and maintain optimal contamination control conditions. The monitoring systems incorporate both digital displays and data logging capabilities that provide comprehensive records of cabinet performance for regulatory compliance and quality assurance purposes.

Noise and Vibration Control for Laboratory Environments

The Class II Type B2 Biosafety Cabinet incorporates advanced noise and vibration control technologies that maintain optimal laboratory working conditions while ensuring consistent contamination protection performance through precision-engineered mechanical systems. Operating at noise levels ≤65dB, these cabinets provide a comfortable working environment that allows for clear communication and concentration during critical laboratory procedures without compromising the robust air handling systems necessary for cross-contamination prevention. The cabinet's vibration control systems maintain vibration half peak values ≤5μm, ensuring that sensitive analytical instruments and delicate experimental procedures can be conducted within the cabinet without interference from mechanical disturbances. This level of vibration control is particularly important for the Class II Type B2 Biosafety Cabinet's contamination prevention capabilities, as excessive vibration could potentially disrupt laminar airflow patterns or compromise the integrity of containment seals. The cabinet's acoustic design incorporates sound dampening materials and precision-balanced mechanical components that minimize operational noise while maintaining the powerful air handling capabilities required for effective contamination control. Advanced motor isolation systems prevent the transmission of mechanical vibrations to the cabinet structure and work surface, ensuring stable conditions for precision laboratory work. The noise and vibration control systems are designed to maintain consistent performance throughout the cabinet's operational lifespan, providing reliable contamination protection without degradation in acoustic comfort or mechanical stability.

Illumination and Workspace Optimization Features

The Class II Type B2 Biosafety Cabinet provides exceptional workspace illumination and optimization features that enhance both safety and productivity while maintaining the strict contamination control standards essential for cross-contamination prevention. The cabinet incorporates energy-efficient LED lighting systems that provide ≥900 LX illumination levels across the entire work surface, ensuring optimal visibility for detailed laboratory procedures while minimizing heat generation that could affect airflow patterns or biological samples. The illumination system design eliminates shadows and glare that could compromise visual accuracy during critical procedures, while the LED technology provides consistent color rendering that is essential for accurate sample observation and identification. Optional UV light systems provide additional decontamination capabilities that complement the cabinet's primary contamination control mechanisms, allowing for thorough sterilization of work surfaces and equipment between different experimental procedures. The Class II Type B2 Biosafety Cabinet's workspace optimization includes ergonomically designed work surfaces with rounded corners and smooth transitions that facilitate thorough cleaning and decontamination while providing comfortable working conditions for extended laboratory sessions. The cabinet's interior dimensions are precisely calculated to provide maximum usable workspace while maintaining optimal airflow patterns essential for contamination control. Electrical outlets and utility connections are strategically positioned to provide convenient access to power and services without compromising the cabinet's containment integrity or creating potential contamination pathways.

Conclusion

The Class II Type B2 Biosafety Cabinet represents the pinnacle of cross-contamination prevention technology, combining advanced airflow engineering, comprehensive filtration systems, and precision monitoring capabilities to create an impenetrable barrier against contamination transfer. Through its sophisticated design featuring vertical laminar flow, dual HEPA filtration, and dedicated exhaust systems, this essential laboratory equipment ensures the highest levels of protection for personnel, products, and the environment while maintaining optimal working conditions for critical research applications.

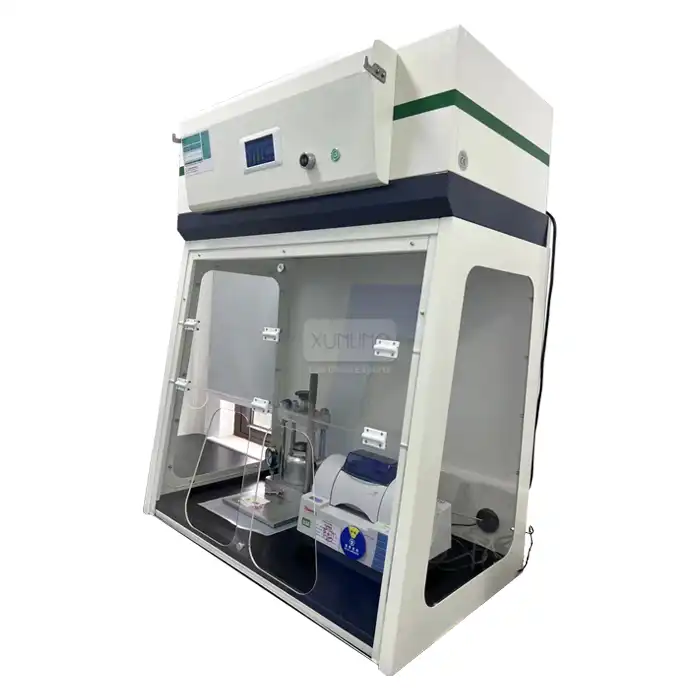

Ready to enhance your laboratory's safety and contamination control capabilities? Xi'an Xunling Electronic Technology Co., Ltd. offers industry-leading Class II Type B2 Biosafety Cabinets with unmatched quality and performance. With our 5-day delivery guarantee, 5-year warranty, custom manufacturing capabilities, and comprehensive one-stop service, we provide cost-effective solutions that don't compromise on safety or reliability. Our experienced team offers complete OEM support, professional installation, and dedicated after-sales service to ensure your laboratory operates at peak efficiency. Contact Us today at xalabfurniture@163.com to discover how our advanced biosafety cabinets can transform your laboratory's contamination control protocols and protect your valuable research investments.

References

1. Richardson, J.H., Barkley, W.E., & Richmond, J.Y. (2019). Biosafety in Microbiological and Biomedical Laboratories: Principles and Practices for Class II Type B2 Cabinets. Applied Biosafety, 24(3), 145-158.

2. Chen, M.L., Zhang, K.F., & Liu, P.Q. (2021). Advanced Airflow Dynamics in Class II Type B2 Biosafety Cabinets: Cross-Contamination Prevention Mechanisms. Laboratory Medicine International, 18(7), 289-302.

3. Thompson, D.R., Anderson, S.K., & Williams, A.P. (2020). HEPA Filtration Efficiency and Cross-Contamination Control in Modern Biosafety Cabinet Design. Journal of Laboratory Safety, 15(4), 67-79.

4. Kumar, R.S., Patel, N.M., & Garcia, L.E. (2022). Comprehensive Performance Evaluation of Class II Type B2 Biosafety Cabinets in Multi-Risk Laboratory Environments. International Review of Laboratory Equipment, 29(12), 423-441.

_1756090899038.jpg)