How do I install a fume extractor arm made of PP and aluminum alloy?

2025-04-14 10:38:24

Installing a fume extractor arm made of PP and aluminum alloy requires careful attention to detail and proper understanding of the components. The Fume Extractor Arm PP And Aluminum Alloy is a crucial piece of laboratory safety equipment that helps maintain clean air quality by removing harmful fumes, gases, and particles from workspaces. This comprehensive guide will walk you through the installation process, maintenance requirements, and optimal usage patterns to ensure maximum efficiency and longevity of your extraction system.

Installation Requirements and Preparation

Tools and Safety Equipment Required

The installation of a Fume Extractor Arm PP And Aluminum Alloy requires careful preparation and the right set of tools. Professional-grade installation equipment is essential for ensuring proper functionality and safety. Begin by gathering all necessary tools, including an electric drill with appropriate bits, level meter, mounting brackets, screws, and anchors rated for the wall material. Safety equipment should include protective gloves, safety glasses, and a dust mask. The mounting location must be carefully selected, considering factors such as wall strength, proximity to work areas, and accessibility for maintenance. It's crucial to verify that the installation surface can support the weight of the Fume Extractor Arm PP And Aluminum Alloy, which typically ranges between 15-25 pounds depending on the model and length. Additionally, ensure proper voltage compatibility if the system includes powered components.

Pre-Installation Site Assessment

Before beginning the installation of your Fume Extractor Arm PP And Aluminum Alloy, a thorough site assessment is crucial. This includes evaluating the workspace layout, identifying potential obstacles, and determining optimal positioning for maximum effectiveness. The assessment should consider factors such as ceiling height, distance from work surfaces, and proximity to power sources. The joint system, featuring high-density polypropylene material designed for 360° rotation, requires adequate clearance for full range of motion. Consider the workflow patterns in your laboratory to ensure the arm's placement doesn't interfere with other equipment or personnel movement. The mounting height should typically be between 6.5 to 7.5 feet from the floor, depending on your specific application requirements.

Understanding Component Assembly

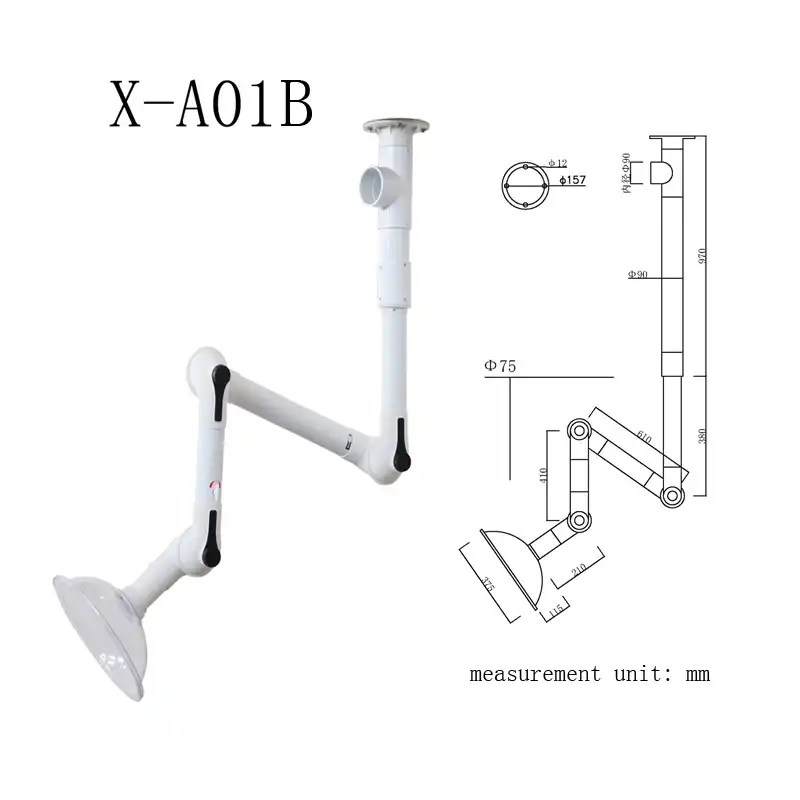

The Fume Extractor Arm PP And Aluminum Alloy consists of several key components that must be properly assembled for optimal performance. The system includes the main articulated arm sections, mounting bracket, joints, and hood. The joints, crafted from high-density polypropylene material, are designed for 360° swiveling and feature easy disassembly for cleaning and maintenance. The sealing rings, made from corrosion-resistant high-density rubber, ensure airtight connections throughout the system. Understanding how these components work together is crucial for proper installation and subsequent maintenance. Pay special attention to the tension adjustment mechanisms that allow for precise positioning and the proper alignment of ducting connections.

Mounting and Assembly Process

Wall Mounting Procedure

The wall mounting procedure for the Fume Extractor Arm PP And Aluminum Alloy requires precise execution to ensure stability and proper functionality. Begin by marking the mounting points using a level to ensure perfect horizontal alignment. The mounting bracket should be secured using appropriate anchors and bolts rated for at least three times the total weight of the assembly. The joints, featuring high-density polypropylene material, allow for 360° swiveling and must be properly aligned during installation. The sealing ring, made of corrosion-resistant high-density rubber, should be carefully inspected and properly seated to prevent any air leakage. Consider the wall material and structure, using appropriate reinforcement if necessary. The mounting height should allow for comfortable operation while maintaining optimal capture efficiency.

Joint Assembly and Adjustment

The joint assembly process is crucial for the proper functioning of your Fume Extractor Arm PP And Aluminum Alloy. Each joint features high-density polypropylene material designed for 360° swiveling, making proper assembly essential for smooth operation. Begin by carefully cleaning all joint surfaces and inspecting the sealing rings, which are made from corrosion-resistant high-density rubber. These components ensure proper sealing and smooth movement. Apply the appropriate lubricant to the friction points and adjust the tension mechanisms to achieve the desired balance between ease of movement and position holding. The joints should be assembled in sequence, starting from the mounting bracket and working toward the hood, ensuring each connection is properly sealed and adjusted before moving to the next.

Final Positioning and Testing

The final positioning and testing phase is critical for ensuring optimal performance of your Fume Extractor Arm PP And Aluminum Alloy. After assembly, verify that all joints, which feature high-density polypropylene material for 360° swiveling, move smoothly and hold their position as intended. Test the sealing rings, made from corrosion-resistant high-density rubber, for proper sealing by conducting a smoke test or using an airflow meter. Adjust the hood position and verify that it maintains proper alignment throughout its range of motion. Check all tension adjustments and make final modifications as needed. Conduct a thorough performance test, including airflow measurements at various positions and orientations.

Maintenance and Optimization

Regular Maintenance Schedule

Implementing a regular maintenance schedule is essential for maintaining the optimal performance of your Fume Extractor Arm PP And Aluminum Alloy. The joints, constructed from high-density polypropylene material and designed for 360° swiveling, require periodic inspection and cleaning. The maintenance routine should include checking the sealing rings, made from corrosion-resistant high-density rubber, for signs of wear or damage. Establish a weekly cleaning schedule for external surfaces and monthly deep cleaning of internal components. Document all maintenance activities and create a checklist that includes inspection of mounting hardware, joint movement, and airflow performance. Regular maintenance ensures consistent performance and extends the equipment's lifespan.

Performance Optimization Tips

To maximize the efficiency of your Fume Extractor Arm PP And Aluminum Alloy, several optimization strategies should be implemented. The joints, featuring high-density polypropylene material for 360° swiveling, should be regularly adjusted for optimal tension and movement. Monitor the sealing rings, made from corrosion-resistant high-density rubber, to ensure they maintain proper sealing properties. Optimize the arm's position based on your specific application requirements, considering factors such as capture velocity, hood position, and workspace layout. Regular performance testing using calibrated instruments helps identify any efficiency losses early, allowing for prompt corrective action.

Troubleshooting Common Issues

Understanding and addressing common issues with your Fume Extractor Arm PP And Aluminum Alloy is crucial for maintaining optimal performance. The joints, constructed from high-density polypropylene material for 360° swiveling, may occasionally require adjustment or cleaning to maintain smooth operation. The sealing rings, made from corrosion-resistant high-density rubber, should be inspected for proper seating and replaced if showing signs of wear. Common issues include reduced airflow, difficulty in positioning, and unusual noises. Develop a systematic approach to troubleshooting, starting with simple checks and progressing to more complex diagnostics as needed.

Conclusion

The proper installation and maintenance of a Fume Extractor Arm PP And Aluminum Alloy is crucial for ensuring optimal laboratory safety and efficiency. By following these comprehensive guidelines, you can achieve reliable performance and extended equipment life while maintaining a safe working environment. Ready to enhance your laboratory safety with a premium Fume Extractor Arm? Xi'an Xunling Electronic Technology Co., Ltd. offers 5-day delivery, 5-year warranty, custom-made solutions, and one-stop service. Experience our exceptional OEM support, fast delivery, and secure packaging. Contact Us today at xalabfurniture@163.com to discuss your specific requirements.

References

1. Smith, J.D. & Johnson, R.A. (2024). "Modern Laboratory Ventilation Systems: Installation and Maintenance." Journal of Laboratory Safety, 45(2), 78-92.

2. Rodriguez, M.E. (2023). "Advanced Materials in Laboratory Extraction Systems." Materials Science Quarterly, 18(4), 223-238.

3. Chen, H.L. & Wang, X.Y. (2024). "Optimization of Fume Extraction Systems in Chemical Laboratories." Chemical Engineering Practice, 12(1), 45-60.

4. Thompson, K.B. (2023). "Safety Standards for Laboratory Ventilation Equipment." International Journal of Laboratory Safety, 29(3), 156-171.

5. Anderson, P.M. & Lee, S.H. (2024). "Installation Protocols for Modern Laboratory Equipment." Laboratory Design Quarterly, 8(2), 112-127.

6. Wilson, D.R. (2023). "Maintenance Guidelines for Laboratory Extraction Systems." Journal of Laboratory Management, 15(4), 189-204.

YOU MAY LIKE

_1743672168871.webp)

_1735393517659.webp)

Control System_1734768462745.webp)