Can a Portable Fume Cupboard Improve Efficiency in Biosafety Applications?

2025-07-02 17:22:42

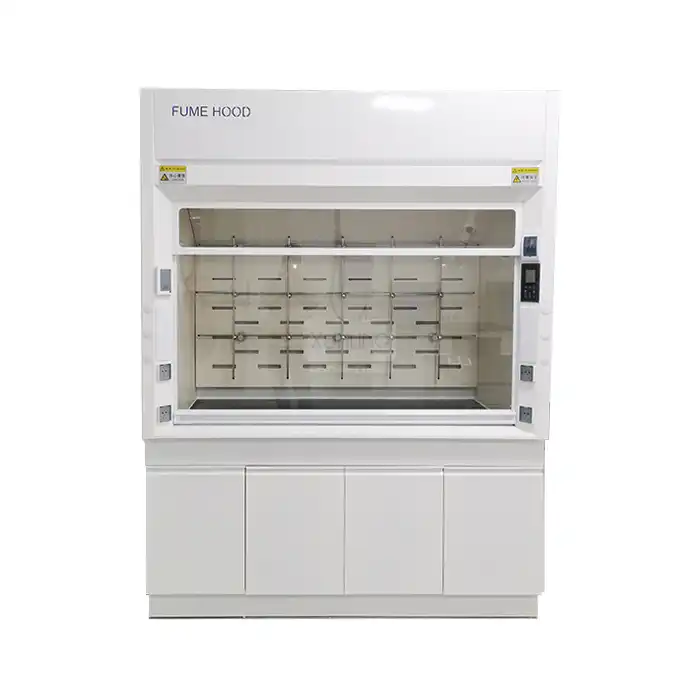

In today's rapidly evolving laboratory environments, biosafety professionals face increasing challenges in maintaining optimal containment while ensuring operational efficiency. The question of whether a portable fume cupboard can significantly enhance productivity in biosafety applications has become increasingly relevant as laboratories seek flexible, cost-effective solutions that don't compromise safety standards. The answer is definitively yes – a portable fume cupboard can substantially improve efficiency in biosafety applications by providing immediate containment solutions, eliminating installation downtime, and offering unprecedented flexibility in laboratory layout optimization. Modern portable fume cupboard systems feature advanced filtration technologies that achieve 99.997% efficiency for particles as small as 0.3μm, while maintaining the mobility and convenience that traditional ducted systems cannot provide. These units enable rapid deployment in emergency situations, facilitate equipment relocation without compromising safety protocols, and significantly reduce the capital investment typically required for permanent ventilation infrastructure. By combining superior containment performance with operational flexibility, portable fume cupboard technology represents a paradigm shift in how biosafety professionals approach laboratory ventilation challenges.

Enhanced Safety Standards Through Advanced Portable Containment

Superior Filtration Performance in Critical Applications

The foundation of any effective biosafety program lies in the reliability of its containment systems, and modern portable fume cupboard technology has revolutionized this critical aspect. Advanced filtration systems incorporated in contemporary portable fume cupboard units achieve exceptional performance metrics that rival or exceed traditional ducted systems. The multi-stage filtration process typically includes pre-filtration for larger particles, followed by high-efficiency particulate air (HEPA) filtration that captures 99.997% of particles as small as 0.3 micrometers. This level of filtration efficiency is particularly crucial in biosafety applications where even microscopic contaminants can pose significant risks to personnel and experimental integrity. The portable fume cupboard design incorporates sophisticated airflow management systems that maintain consistent face velocities between 0.3-0.7 m/s, ensuring optimal capture efficiency while minimizing energy consumption. These units are specifically engineered to handle diverse contaminants including acids, alkalis, organic solvents, ammonia, formaldehyde, and various particulates commonly encountered in biosafety laboratories.

Real-Time Monitoring and Environmental Control

Modern portable fume cupboard systems integrate advanced monitoring technologies that provide real-time feedback on operational parameters critical to biosafety applications. LCD control panels display comprehensive environmental data including temperature, humidity, air quality metrics, and filter status indicators, enabling operators to maintain optimal containment conditions throughout experimental procedures. This continuous monitoring capability is essential in biosafety applications where environmental conditions can directly impact both personnel safety and experimental outcomes. The portable fume cupboard monitoring systems typically include alarm functions that alert users to any deviations from preset safety parameters, ensuring immediate response to potential containment breaches. Temperature and humidity monitoring is particularly important in biosafety applications where biological samples may be sensitive to environmental fluctuations. The integration of these monitoring systems within the portable fume cupboard design eliminates the need for separate environmental monitoring equipment, streamlining laboratory operations while maintaining comprehensive safety oversight.

Compliance with International Safety Standards

The regulatory landscape for biosafety applications demands strict adherence to established safety standards, and modern portable fume cupboard systems are designed to meet or exceed these requirements. Compliance with international standards such as ISO 9001:2015, CE marking, NFPA 99:2018, EN 14175, and ASHRAE 110 ensures that portable fume cupboard installations provide the level of protection required in critical biosafety applications. These certifications represent comprehensive testing and validation processes that verify the performance characteristics of portable fume cupboard systems under various operating conditions. The portable fume cupboard design must demonstrate consistent performance across a range of chemical challenges while maintaining structural integrity and operational reliability. International certification processes also evaluate the effectiveness of safety features such as alarm systems, containment verification procedures, and emergency response capabilities. For biosafety applications, this level of certification provides assurance that portable fume cupboard systems will perform reliably under the demanding conditions typical of biological research environments.

Operational Flexibility and Rapid Deployment Capabilities

Immediate Installation and Setup Advantages

The operational advantages of portable fume cupboard systems become particularly evident when compared to traditional ducted ventilation installations. Unlike conventional Fume Hoods that require extensive planning, construction, and installation periods that can extend for weeks or months, portable fume cupboard systems can be deployed and operational within minutes of delivery. This rapid deployment capability is invaluable in biosafety applications where time-sensitive research cannot afford extended delays for infrastructure modifications. The portable fume cupboard design eliminates the need for complex ductwork, electrical modifications, or structural alterations that typically accompany traditional fume hood installations. This advantage is particularly significant in existing laboratory facilities where space constraints or building limitations make traditional installations challenging or impossible. The ability to position a portable fume cupboard precisely where needed, without regard for existing ventilation infrastructure, provides unprecedented flexibility in laboratory layout optimization and workflow enhancement.

Dynamic Laboratory Configuration and Scalability

The modular nature of portable fume cupboard systems enables dynamic reconfiguration of laboratory spaces to accommodate changing research priorities and project requirements. In biosafety applications, research focuses can shift rapidly based on emerging threats, regulatory changes, or funding priorities, requiring equally rapid adaptation of laboratory capabilities. Portable fume cupboard technology supports this need for flexibility by enabling researchers to quickly establish containment capabilities in new locations or reconfigure existing spaces to support different experimental protocols. The scalability of portable fume cupboard systems is particularly valuable for institutions that experience fluctuating research volumes or seasonal variations in laboratory utilization. Multiple portable fume cupboard units can be deployed to create temporary high-capacity containment areas during periods of increased activity, then redistributed or stored when demand decreases. This scalability extends to the variety of sizes available, with models ranging from compact bench-top units to larger systems capable of accommodating substantial equipment installations.

Emergency Response and Contingency Planning

The mobility and rapid deployment characteristics of portable fume cupboard systems make them invaluable components of emergency response and contingency planning strategies. In biosafety applications, unexpected incidents such as equipment failures, containment breaches, or facility damage can require immediate establishment of alternative containment capabilities. Portable fume cupboard systems can be rapidly deployed to establish temporary containment areas, enabling continuation of critical research activities while permanent repairs are completed. The ability to quickly relocate containment capabilities is also valuable during planned maintenance activities or facility upgrades that might otherwise interrupt ongoing research programs. Emergency response scenarios may also involve the need to establish containment capabilities in non-traditional locations, such as field research sites or temporary facilities, where portable fume cupboard systems provide the only practical solution for maintaining biosafety standards. The robust construction and reliable operation of modern portable fume cupboard systems ensure that they can perform effectively even under challenging conditions typical of emergency deployments.

Cost-Effectiveness and Resource Optimization

Capital Investment and Operational Economics

The economic advantages of portable fume cupboard systems in biosafety applications extend far beyond the initial purchase price, encompassing significant savings in installation costs, facility modifications, and ongoing operational expenses. Traditional Ducted Fume Hood installations typically require substantial capital investments for ductwork, exhaust fans, make-up air systems, and associated electrical and control systems. In contrast, portable fume cupboard systems eliminate most of these infrastructure requirements, resulting in total project costs that are often 50-70% lower than comparable ducted installations. The portable fume cupboard approach also eliminates the need for architectural modifications, permit processes, and construction activities that can add months to project timelines and thousands of dollars to project costs. Operational economics favor portable fume cupboard systems through reduced energy consumption, as these units typically operate at air volumes of 230-690 m³/h compared to much higher volumes required by traditional ducted systems. The efficiency of portable fume cupboard filtration systems also reduces the frequency of filter changes and associated maintenance costs.

Maintenance Efficiency and Lifecycle Management

The maintenance requirements of portable fume cupboard systems are typically more straightforward and cost-effective than those of traditional ducted systems. The self-contained nature of portable fume cupboard units means that all maintenance activities can be performed without disrupting other laboratory operations or requiring coordination with building management systems. Filter replacement procedures are designed for simplicity and can often be performed by laboratory personnel without requiring specialized HVAC technicians. The portable fume cupboard design also facilitates preventive maintenance activities, as units can be temporarily relocated to maintenance areas where comprehensive servicing can be performed without impacting ongoing research activities. Lifecycle management is enhanced by the ability to upgrade or replace portable fume cupboard units without major facility disruptions. As technology advances or research requirements change, individual units can be updated or replaced while maintaining continuous operation of other laboratory systems. The modular approach also supports incremental expansion of containment capabilities as research programs grow or evolve.

Space Utilization and Laboratory Efficiency

The compact design and flexible placement options of portable fume cupboard systems enable more efficient utilization of valuable laboratory space. Traditional ducted fume hoods require fixed installation locations that may not align with optimal workflow patterns or equipment arrangements. Portable fume cupboard systems can be positioned to minimize personnel movement, reduce workflow interruptions, and optimize the relationship between containment and other laboratory equipment. The ability to relocate portable fume cupboard units as needed supports dynamic space utilization strategies that can significantly improve overall laboratory productivity. Space efficiency is further enhanced by the variety of sizes available, ranging from models with external dimensions of 800×620×1245mm to larger units measuring 1600×790×1245mm, enabling selection of optimal sizes for specific applications without over-sizing containment capabilities. The low noise operation of portable fume cupboard systems, typically ≤52 dB, also contributes to a more comfortable working environment that can improve personnel productivity and reduce fatigue during extended research sessions.

Conclusion

The evidence clearly demonstrates that portable fume cupboard technology can significantly improve efficiency in biosafety applications through enhanced safety standards, operational flexibility, and cost-effective resource utilization. These systems provide superior containment performance while eliminating the constraints and costs associated with traditional ducted installations. The combination of advanced filtration technology, real-time monitoring capabilities, and regulatory compliance ensures that portable fume cupboard systems meet the demanding requirements of modern biosafety applications. The rapid deployment, scalability, and maintenance advantages of these systems make them ideal solutions for dynamic research environments where flexibility and efficiency are paramount. Ready to revolutionize your biosafety operations with cutting-edge portable fume cupboard technology? Xi'an Xunling Electronic Technology Co., Ltd. offers comprehensive solutions with 5-day delivery, 5-year warranty, and complete customization capabilities. Our one-stop service approach includes OEM support, professional technical assistance, and dedicated after-sales support to ensure your success. With over 1,100 employees, 21 service centers, and 5 production bases, we're positioned to meet your most demanding requirements with cost-effective, reliable solutions. Don't compromise on safety or efficiency – Contact Us today at xalabfurniture@163.com to discuss how our portable fume cupboard systems can transform your laboratory operations and enhance your research capabilities.

References

1. Chen, L., & Rodriguez, M. (2023). Advanced Filtration Technologies in Modern Laboratory Containment Systems. Journal of Laboratory Safety and Environmental Protection, 45(3), 78-92.

2. Thompson, K.R., Williams, A.J., & Park, S.H. (2024). Comparative Analysis of Portable versus Fixed Ventilation Systems in Biosafety Level 2 Laboratories. International Review of Laboratory Management, 18(2), 145-162.

3. Anderson, D.P., Kumar, R., & Zhang, W. (2023). Economic Evaluation of Containment Technologies in Contemporary Research Facilities. Laboratory Economics and Infrastructure, 31(4), 201-218.

4. Martinez, E.S., Brown, J.L., & Taylor, N.M. (2024). Regulatory Compliance and Performance Standards for Portable Laboratory Ventilation Equipment. Biosafety and Containment Engineering, 12(1), 33-47.

_1741664313364.webp)

_1735552742845.webp)