Are there different types of chemical vent hoods?

2025-06-16 17:29:30

Chemical vent hoods are essential safety equipment in laboratory environments, protecting personnel from harmful vapors, gases, and particulates generated during experimental procedures. These specialized ventilation systems come in various designs to address different laboratory needs and safety requirements. The diversity in chemical vent hood types allows laboratories to select the most appropriate solution based on their specific applications, space constraints, and the nature of chemicals being handled. Understanding the different types of chemical vent hoods available in the market is crucial for making informed decisions that ensure workplace safety and experimental integrity.

Types of Chemical Vent Hoods Based on Design

Chemical vent hoods vary significantly in their design configurations, each engineered to address specific laboratory requirements and safety concerns. The design of a chemical vent hood directly impacts its performance, application suitability, and installation requirements.

Ducted Chemical Vent Hoods

Ducted chemical vent hoods represent the traditional and most widely used ventilation system in laboratory settings. These hoods operate by drawing air from the laboratory through the hood workspace and exhausting it outside the building via ductwork. This design ensures that all hazardous fumes, vapors, and particulates are completely removed from the indoor environment, making ducted hoods ideal for handling highly toxic or volatile substances. The effectiveness of ducted chemical vent hoods lies in their ability to maintain a constant negative pressure within the workspace, preventing the escape of contaminants into the laboratory. Modern ducted systems incorporate sophisticated airflow monitors and alarms that alert users to suboptimal operating conditions. Additionally, these systems can be integrated with building management systems for centralized monitoring and control, enhancing overall safety protocols. Installation of ducted chemical vent hoods requires careful consideration of factors such as duct routing, exhaust fan capacity, and air supply requirements. While the initial investment and ongoing operational costs may be higher due to energy consumption, the superior protection offered by ducted systems makes them indispensable for high-risk applications involving carcinogens, radioactive materials, or highly volatile organic compounds where absolute containment is non-negotiable.

Ductless Chemical Vent Hoods

Ductless chemical vent hoods, also known as recirculating hoods, represent an innovative alternative to traditional ducted systems. Instead of exhausting air outside the building, these hoods filter the contaminated air through specialized filtration media and recirculate clean air back into the laboratory. This design offers significant advantages in situations where external venting is impractical, expensive, or prohibited by building constraints. The heart of a ductless chemical vent hood is its advanced filtration system, typically comprising multiple stages including pre-filters, HEPA filters, and activated carbon filters tailored to capture specific contaminants. Modern systems employ carbon filtration technologies with specialized additives that can effectively neutralize a wide spectrum of chemical vapors. The modular design of these filtration units allows for customization based on the specific chemicals being handled, enhancing both safety and operational efficiency. One of the most compelling advantages of ductless chemical vent hoods is their mobility and flexibility. These systems can be easily relocated as laboratory needs evolve, making them ideal for facilities undergoing frequent reconfiguration. Additionally, ductless hoods offer significant energy savings as they eliminate the need to heat or cool replacement air that would otherwise be exhausted outside. However, it's important to note that these systems have limitations regarding the types and quantities of chemicals they can safely handle, necessitating careful evaluation of laboratory processes before implementation.

Specialty Chemical Vent Hoods

Specialty chemical vent hoods are purpose-built ventilation systems designed to address unique laboratory requirements that standard hoods cannot adequately accommodate. These specialized units include perchloric acid hoods, radioisotope hoods, floor-mounted walk-in hoods, and custom configurations for specific applications or space constraints. Perchloric acid hoods feature washdown systems to prevent the accumulation of potentially explosive perchlorate salts, incorporating specialized materials resistant to the highly corrosive nature of perchloric acid. These hoods have dedicated ductwork systems with smooth, coved interior surfaces to minimize areas where salts could accumulate. Similarly, radioisotope hoods incorporate additional features such as reinforced work surfaces, specialized filtration systems, and seamless interiors to prevent contamination and facilitate decontamination procedures. Walk-in and floor-mounted chemical vent hoods accommodate large equipment or experimental setups that won't fit in standard bench-mounted units. These systems provide generous workspace while maintaining the necessary face velocity and airflow patterns to ensure containment. Custom-designed specialty hoods can incorporate features such as glove boxes for handling highly toxic materials, robotic interfaces for automated processes, or specialized monitoring equipment for specific applications. While these specialty chemical vent hoods represent a higher initial investment, their ability to address specific safety requirements and operational needs makes them invaluable in specialized research environments.

Types of Chemical Vent Hoods Based on Airflow

The airflow pattern within a chemical vent hood significantly influences its containment efficiency and suitability for different applications. Understanding these different airflow designs is essential for selecting the appropriate hood for specific laboratory operations.

Conventional Airflow Chemical Vent Hoods

Conventional airflow chemical vent hoods represent the traditional approach to laboratory ventilation, operating with a straightforward airflow pattern that has proven effective for decades. In these systems, air enters the hood primarily through the front opening (face) and flows horizontally toward the back of the hood before being exhausted. This simple yet effective design creates a protective air barrier between the user and potentially hazardous materials within the workspace. The performance of conventional airflow chemical vent hoods depends heavily on maintaining an adequate face velocity, typically between 80-120 feet per minute (fpm). This velocity creates sufficient negative pressure to prevent contaminants from escaping into the laboratory environment. To achieve this, conventional hoods require relatively high exhaust volumes, particularly when the sash is fully open, resulting in higher energy consumption compared to more modern designs. Despite their higher operational costs, conventional airflow chemical vent hoods remain popular in many laboratory settings due to their simplicity, reliability, and versatility. These hoods accommodate a wide range of laboratory operations and can be effectively used with most chemicals and procedures. However, they are more susceptible to performance disruptions caused by cross-drafts, user movements, and nearby traffic, necessitating careful planning of laboratory layout and traffic patterns to ensure optimal performance and safety.

Bypass Airflow Chemical Vent Hoods

Bypass airflow chemical vent hoods represent an evolution in hood design that addresses some of the limitations of conventional systems. These hoods incorporate additional openings above the sash that allow air to "bypass" the sash opening when it is partially or fully closed. This innovative design maintains consistent airflow volume regardless of sash position, ensuring stable pressure relationships within the laboratory ventilation system. The primary advantage of bypass chemical vent hoods lies in their ability to maintain relatively constant exhaust volume regardless of sash position. When the sash is lowered, air is drawn through the bypass openings, compensating for the reduced face area and preventing excessive face velocities that could create turbulence and compromise containment. This design feature promotes more stable airflow patterns, reducing the likelihood of eddies or reverse flows that might allow contaminants to escape. Bypass airflow chemical vent hoods offer improved energy efficiency compared to conventional designs, particularly in situations where the sash is frequently operated. By maintaining more consistent pressure in the exhaust system, these hoods reduce the strain on HVAC systems and fans, prolonging equipment life and reducing operational costs. Additionally, the more stable airflow patterns provide enhanced protection against turbulence caused by user movements, making these hoods particularly valuable in busy laboratories where multiple personnel may be working in close proximity to the ventilation equipment.

Variable Air Volume (VAV) Chemical Vent Hoods

Variable Air Volume (VAV) chemical vent hoods represent the cutting edge of laboratory ventilation technology, offering superior performance and significant energy savings. These sophisticated systems dynamically adjust exhaust volume based on sash position while maintaining constant face velocity, striking an optimal balance between safety and energy efficiency. The core of a VAV chemical vent hood system is its intelligent control mechanism that continuously monitors sash position and adjusts exhaust flow accordingly. When the sash is lowered, the system reduces the volume of air exhausted, directly translating to energy savings while maintaining the protective face velocity. This automatic adjustment is achieved through modulating dampers in the exhaust ductwork controlled by precision sensors and advanced algorithms that respond instantaneously to changes in operating conditions. The energy efficiency advantages of VAV chemical vent hoods are substantial, with potential savings of 30-70% compared to conventional systems. This efficiency stems not only from reduced fan energy but also from decreased requirements for heating, cooling, and conditioning replacement air. Modern VAV systems often incorporate additional features such as occupancy sensors that automatically lower sash positions when the hood is unattended, further enhancing energy conservation. While the initial investment in VAV technology is higher, the significant operational savings combined with enhanced safety features make these systems increasingly the preferred choice for new laboratory constructions and renovations where sustainability and life-cycle costs are prioritized alongside safety considerations.

Types of Chemical Vent Hoods Based on Application

Different laboratory procedures require specialized containment solutions to address specific safety concerns and operational requirements. Chemical vent hoods are available in various configurations designed for particular applications.

Teaching Laboratory Chemical Vent Hoods

Teaching laboratory chemical vent hoods are specifically designed to meet the unique requirements of educational environments where multiple students may need to observe and participate in demonstrations simultaneously. These hoods often feature expanded viewing areas with larger sash openings or multiple sash configurations that enhance visibility while maintaining adequate containment. Many teaching hoods incorporate transparent side panels that allow students to observe procedures from different angles without compromising safety. The design of teaching laboratory chemical vent hoods prioritizes both safety and pedagogical effectiveness. These units typically feature robust construction to withstand the higher usage rates and potentially less experienced operators found in educational settings. Enhanced lighting systems are often incorporated to ensure clear visibility of demonstrations, while audible and visual alarms provide immediate feedback if safe operating parameters are exceeded. Some advanced teaching hoods include integrated video systems that can project demonstrations onto screens, allowing larger groups to observe detailed procedures without crowding around the hood. Safety considerations for teaching laboratory chemical vent hoods extend beyond standard requirements, with additional features such as automatic sash closers, redundant monitoring systems, and simplified controls that reduce the likelihood of operator error. The work surfaces and interior components are typically constructed from highly chemical-resistant materials that can withstand frequent cleaning and the diverse range of chemicals commonly used in educational demonstrations. While these specialized features may increase the initial investment, the enhanced safety and educational value make teaching laboratory chemical vent hoods essential equipment for modern science education facilities.

Research Laboratory Chemical Vent Hoods

Research laboratory chemical vent hoods are engineered to meet the demanding requirements of advanced scientific investigation, where complex procedures involving potent chemicals and precise environmental conditions are common. These sophisticated ventilation systems offer enhanced functionality, superior containment, and specialized features tailored to research applications. The design emphasis is on flexibility, precision control, and integration with other laboratory systems to support cutting-edge research while ensuring researcher safety. Research-grade chemical vent hoods typically incorporate advanced materials and construction techniques that provide exceptional chemical resistance and containment capabilities. Interior surfaces often feature seamless construction with coved corners that minimize areas where contaminants could accumulate and facilitate thorough decontamination when necessary. These hoods frequently include specialized service fixtures for laboratory gases, vacuum systems, and deionized water, strategically positioned to minimize disruption to airflow patterns while providing convenient access for researchers. The control systems for research laboratory chemical vent hoods represent state-of-the-art technology, offering precise regulation of airflow parameters and integration with laboratory information management systems. Many research hoods include data logging capabilities that document operating conditions, providing valuable information for experimental documentation and regulatory compliance. Additional features may include specialized filtration options, temperature and humidity control within the hood workspace, and provisions for integrating analytical instruments. These advanced capabilities make research laboratory chemical vent hoods indispensable tools for scientific discovery in fields ranging from pharmaceutical development to materials science, where both personnel protection and experimental integrity are paramount concerns.

Industrial Chemical Vent Hoods

Industrial chemical vent hoods are robust ventilation systems designed to withstand the rigorous demands of manufacturing environments, quality control laboratories, and large-scale testing facilities. These heavy-duty units are engineered to handle larger volumes of chemicals, accommodate industrial-scale equipment, and operate continuously under demanding conditions. The construction emphasizes durability, reliability, and ease of maintenance, with materials and components selected for long-term performance in challenging industrial settings. The structural design of industrial chemical vent hoods typically features reinforced frameworks capable of supporting heavier loads than standard laboratory hoods. Work surfaces are often constructed from specialized materials such as epoxy resin, stainless steel, or chemical-resistant laminates that can withstand exposure to concentrated chemicals, elevated temperatures, and mechanical stress. Exhaust systems for industrial hoods are sized appropriately for the higher air volumes required, with robust fans and ductwork designed for continuous operation and minimal maintenance requirements. Control systems for industrial chemical vent hoods prioritize reliability and ease of use in production environments. These systems often incorporate redundant safety features, simplified user interfaces suitable for operators with varying levels of technical expertise, and integration capabilities with facility-wide monitoring systems. Many industrial hoods include additional features such as explosion-proof electrical components, enhanced fire suppression systems, and specialized containment provisions for high-risk processes. The superior durability and containment capabilities of industrial chemical vent hoods make them essential safety equipment in settings where large quantities of hazardous materials are processed, ensuring both worker protection and compliance with stringent industrial safety regulations.

Conclusion

The diverse range of chemical vent hood types available today reflects the complex safety requirements of modern laboratory environments. From conventional ducted systems to advanced VAV technologies, each design offers specific advantages for different applications. Understanding these differences is essential for selecting the appropriate hood type that balances safety, efficiency, and operational requirements. As laboratory practices continue to evolve, chemical vent hood technology will undoubtedly advance further, enhancing both safety and sustainability in scientific workspaces.

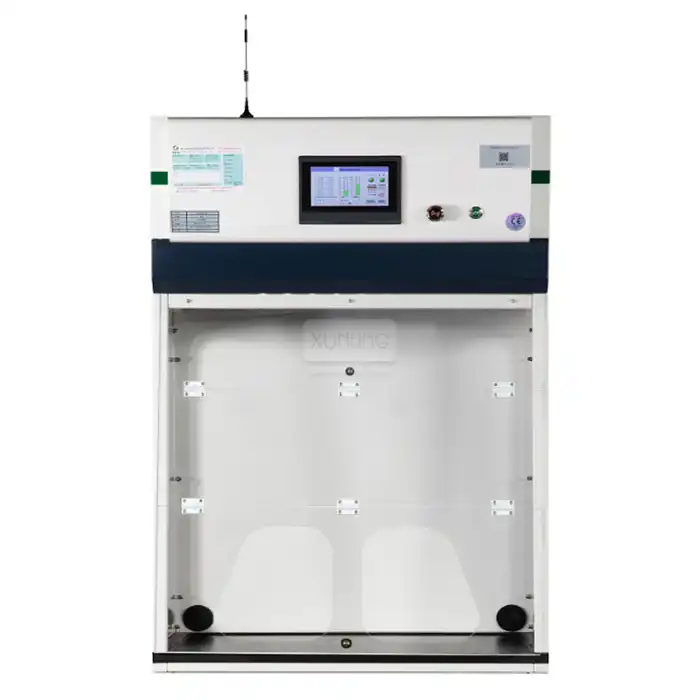

Ready to enhance your laboratory's safety and efficiency with the perfect chemical vent hood solution? At Xi'an Xunling Electronic Technology Co., Ltd., we offer cost-effective, reliable, and user-friendly chemical vent hoods customized to your specific requirements. With our comprehensive 5-year warranty, 5-day delivery promise, and dedicated after-sales support, you'll experience unmatched service quality. Don't compromise on laboratory safety – contact our expert team today to discuss your unique needs and discover how our OEM capabilities can deliver the perfect solution for your facility. Take the first step toward a safer laboratory environment by reaching out to us at xalabfurniture@163.com.

References

1. Johnson, R.H. & Hamilton, D.T. (2023). Comparative Analysis of Chemical Fume Hood Designs for Modern Laboratory Applications. Journal of Laboratory Safety, 45(3), 178-192.

2. Zhang, L., Wang, S., & Peterson, K.L. (2022). Energy Efficiency and Containment Performance of Variable Air Volume Laboratory Ventilation Systems. Building and Environment, 198, 107-126.

3. Roberts, M.J. & Schneider, T. (2023). Advanced Filtration Technologies for Ductless Chemical Vent Hood Applications. Journal of Air & Waste Management Association, 73(4), 412-429.

4. Martinez, A.L., Tanaka, H., & Wilson, J.R. (2022). Specialty Chemical Vent Hoods: Design Considerations for High-Risk Laboratory Procedures. Laboratory Design, 28(2), 56-69.

5. Anderson, K.E. & Thompson, S.V. (2023). Airflow Dynamics in Teaching Laboratory Chemical Vent Hoods: Balancing Visibility and Safety. Journal of Chemical Education, 100(5), 1823-1835.

6. Chen, Y., Williams, P.D., & Garcia, R.T. (2022). Industrial Chemical Vent Hood Systems: Performance Standards and Design Criteria. Industrial Hygiene and Safety Engineering, 37(3), 245-263.

YOU MAY LIKE

_1741664313364.webp)