Are ductless fume hoods effective at removing hazardous fumes?

2025-05-04 14:52:48

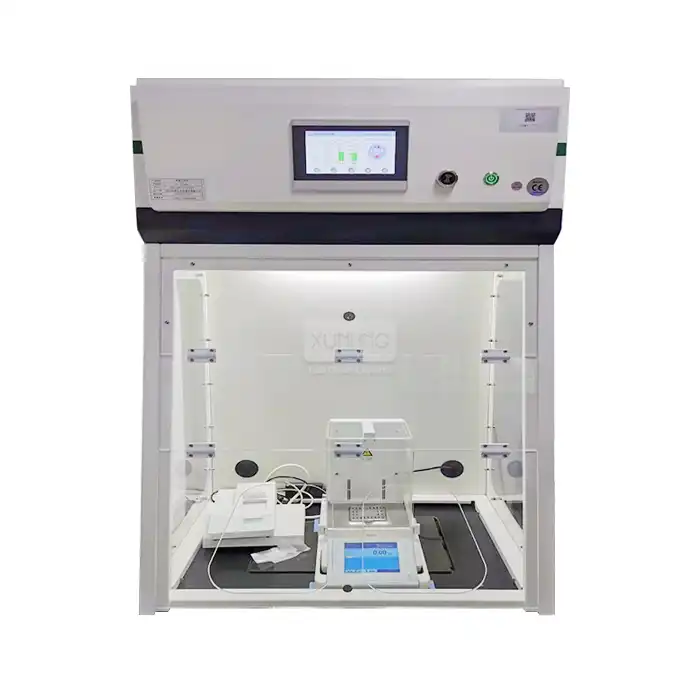

In modern laboratory environments, safety remains paramount when handling hazardous chemicals and volatile substances. Among the essential safety equipment, Ductless Fume Hoods have emerged as a crucial solution for managing potentially dangerous fumes. For laboratory managers and scientists considering implementation options, a common question arises: Are ductless fume hoods truly effective at removing hazardous fumes? The answer is a resounding yes - when properly designed and maintained, a ductless fume hood for lab applications provides exceptional protection through advanced filtration technology and controlled airflow systems, capturing harmful substances before they can enter the breathing zone of laboratory personnel.

The Science Behind Ductless Fume Hood Effectiveness

Understanding how ductless fume hoods work is essential to appreciating their effectiveness. These sophisticated pieces of laboratory equipment employ multiple mechanisms to ensure hazardous fumes are properly contained and neutralized.

Advanced Filtration Technology

The core component that makes a ductless fume hood for lab use so effective is its advanced filtration system. Unlike traditional ducted hoods that simply redirect air outside, ductless models must purify the air before recirculating it back into the laboratory environment. This is accomplished through a multi-stage filtration process typically consisting of pre-filters for larger particles, HEPA filters for microscopic particulates, and specialized chemical filters like activated carbon designed to capture specific chemical compounds. The filtration efficiency of premium models like those manufactured by Xi'an Xunling Electronic Technology Co., Ltd. reaches an impressive 99.997% for particles as small as 0.3μm. This exceptional level of filtration means virtually all harmful particulates are trapped within the system rather than being released into the laboratory atmosphere. The specialized filters are often customized based on the specific chemicals being handled, ensuring optimal protection against acids, alkalis, organic solvents, ammonia, formaldehyde, and various powders. Regular monitoring of filter saturation levels via sophisticated electronic systems ensures that laboratory personnel are alerted when filters require replacement, maintaining consistently high protection levels throughout the equipment's operational life.

Controlled Airflow Dynamics

The effectiveness of a ductless fume hood for lab applications heavily depends on its airflow dynamics. These systems are engineered to create a precise airflow pattern that draws potentially harmful fumes away from the user and into the filtration system. With face velocities ranging from 0.3-0.7m/s and air capacity capabilities between 230-690 m³/h, modern ductless hoods maintain the optimal airflow required for effective containment without disrupting delicate laboratory procedures. The airflow is carefully calibrated to prevent turbulence that might allow fumes to escape while ensuring sufficient negative pressure within the work area. Xi'an Xunling's portable ductless fume hoods feature sophisticated airflow monitoring systems that continuously measure and adjust performance to maintain ideal containment conditions. This is particularly important when handling volatile substances where even minor airflow disruptions could compromise safety. The combination of proper face velocity, laminar flow design, and aerodynamic chamber construction creates an invisible but highly effective barrier between laboratory personnel and hazardous substances.

Real-time Monitoring Systems

Modern ductless fume hood for lab use incorporates sophisticated monitoring technology that continuously evaluates multiple safety parameters. Xi'an Xunling's models feature comprehensive LCD control panels that display critical information including temperature, humidity, air quality, and filter status in real-time. These monitoring systems serve as an early warning mechanism, alerting users to potential issues before they become serious hazards. The integration of electronic sensors throughout the system allows for constant measurement of airflow velocities, ensuring they remain within safe operational parameters. If any values fall outside predetermined safety thresholds, visual and audible alarms immediately notify laboratory personnel. This continuous monitoring capability represents a significant advancement over older laboratory safety equipment, providing users with constant reassurance that their working environment remains protected. Additionally, data logging capabilities in advanced models allow for safety compliance documentation and performance trend analysis, further enhancing laboratory safety protocols and providing valuable information for safety audits or regulatory inspections.

Applications and Versatility of Ductless Fume Hoods

The effectiveness of ductless fume hoods extends across numerous laboratory applications, demonstrating their versatility as essential safety equipment.

Chemical Research and Handling Applications

In chemical research environments, a ductless fume hood for lab use proves invaluable for containing and neutralizing potentially harmful substances. These specialized containment systems excel when handling volatile organic compounds, acids, bases, and other reactive chemicals that pose inhalation hazards. The multi-stage filtration systems in Xi'an Xunling's portable ductless fume hoods are specifically designed to capture chemical vapors through molecular adsorption, chemical neutralization, and particulate filtration mechanisms. For instance, when working with hydrochloric acid or ammonia solutions, the specialized chemical filters effectively remove these corrosive vapors before they can reach the laboratory atmosphere. This capability is particularly crucial during chemical synthesis procedures that generate unpredictable reaction by-products or when working with unknown samples that may emit hazardous components. The effectiveness extends to protecting sensitive analytical instruments from corrosive vapors while simultaneously protecting laboratory personnel. Researchers appreciate that these systems allow them to conduct necessary chemical manipulations without compromising safety or experimental integrity. With models available in various sizes (from the compact DSB800 at 800mm width to the spacious DLB1600 at 1600mm width), laboratories can select appropriately sized units based on specific research requirements and available space constraints.

Pharmaceutical and Biotechnology Safety

The pharmaceutical and biotechnology sectors benefit tremendously from the effectiveness of ductless fume hoods in handling potent compounds and biologically active materials. When developing novel drugs or biotechnological applications, researchers often work with substances that present unique safety challenges at extremely low concentrations. A properly equipped ductless fume hood for lab applications provides the necessary barrier between these substances and laboratory personnel. Xi'an Xunling's portable ductless fume hoods feature the high-efficiency filtration necessary for capturing pharmaceutical powders and aerosols that might otherwise contaminate the laboratory environment. The controlled airflow prevents cross-contamination between different samples or compounds being handled simultaneously, an essential feature when working with valuable or potent materials. The hoods' low noise operation (≤52 dB) ensures researchers can maintain focus during precise procedures without disruptive background noise. This combination of safety features makes these systems ideal for applications ranging from drug formulation and compounding to cell culture media preparation where sterility and contamination control are paramount concerns. Additionally, the easily cleanable work surfaces and spillage trays facilitate compliance with GMP (Good Manufacturing Practice) requirements that are standard in pharmaceutical operations.

Educational and Training Environments

Educational institutions greatly benefit from incorporating ductless fume hoods into their laboratory teaching spaces. These systems provide effective protection while offering several advantages specific to learning environments. A ductless fume hood for lab instruction allows students to observe chemical reactions and laboratory techniques safely while instructors demonstrate proper handling procedures. The compact and portable nature of Xi'an Xunling's ductless fume hoods makes them ideal for educational settings where laboratory configurations may need to change between different courses or semesters. Models like the DSB1000 or DMB1275 provide sufficient workspace for small group demonstrations while maintaining a reasonable footprint within crowded teaching laboratories. Unlike traditional ducted systems, these ductless units require no expensive building modifications or permanent installation, making them cost-effective solutions for educational budgets. The transparent hood design provides excellent visibility for instructional purposes while maintaining effective containment of hazardous fumes. Additionally, the real-time monitoring displays serve an educational purpose themselves, helping students understand the importance of proper airflow and filtration in laboratory safety. The easily portable nature of these systems means they can be shared between different laboratory classrooms as needed, maximizing the institution's investment in safety equipment while ensuring students receive hands-on experience with professional-grade laboratory safety systems they will encounter in their future careers.

Practical Considerations for Optimal Performance

While ductless fume hoods have proven highly effective at removing hazardous fumes, maximizing their performance requires attention to several practical considerations.

Proper Selection and Sizing

Selecting the appropriate ductless fume hood for lab applications requires careful consideration of workspace requirements and intended applications. The effectiveness of any fume hood depends significantly on proper sizing relative to the work being performed inside it. Xi'an Xunling Electronic Technology offers multiple size options ranging from the compact DSB800 (800×620×1245mm external dimensions) to the spacious DLB1600 (1600×790×1245mm external dimensions), accommodating different laboratory needs. When determining the appropriate size, laboratory managers must consider not only the physical dimensions of materials and equipment to be placed inside the hood but also the working space required for safe manipulation of these items. Oversized equipment cramped into a too-small hood can disrupt airflow patterns and compromise containment effectiveness. Conversely, an unnecessarily large hood may waste valuable laboratory space and energy. Proper selection also involves matching the filtration system to specific chemical applications. The filtration modules must be appropriate for the specific hazards being contained – whether organic vapors, acids, bases, or particulates. Xi'an Xunling's technical support team assists customers in determining the optimal configuration based on detailed assessment of intended applications. This consultative approach ensures that laboratories select ductless fume hoods with filtration systems specifically designed for their unique chemical inventory, maximizing both safety and filtration effectiveness while avoiding the expense of unnecessarily complex systems for simpler applications.

Maintenance and Filter Management

The long-term effectiveness of any ductless fume hood for lab use depends critically on proper maintenance and timely filter replacement. Unlike traditional ducted hoods where performance primarily relates to motor function and airflow, ductless systems require additional attention to filter condition and saturation levels. Xi'an Xunling's portable ductless fume hoods incorporate sophisticated monitoring systems that continuously evaluate filter status, alerting users when replacement becomes necessary. This proactive approach prevents situations where degraded filters might compromise safety. Regular maintenance schedules should include inspection of all gaskets and seals to ensure the integrity of the containment system, verification of proper airflow patterns using visualization techniques, and calibration of monitoring sensors to maintain accuracy. The filter management process should follow a comprehensive protocol including documentation of installation dates, estimated lifespan based on usage patterns, and scheduled evaluations. Laboratory managers should maintain detailed logs of chemicals used within the hood to help predict filter saturation rates and plan replacement schedules accordingly. Xi'an Xunling provides comprehensive maintenance guidelines along with professional technical support services to ensure optimal system performance throughout the equipment's operational life. Their support team can assist with establishing appropriate maintenance intervals based on specific laboratory applications and usage patterns. With proper attention to these maintenance requirements, a quality ductless fume hood can provide years of reliable protection, making them a cost-effective long-term investment in laboratory safety.

Integration with Laboratory Workflow

For a ductless fume hood for lab applications to be truly effective, it must seamlessly integrate into existing laboratory workflows without creating unnecessary operational complications. The portable nature of Xi'an Xunling's ductless fume hoods offers significant advantages in this regard. Unlike traditional ducted systems that permanently define workspace configurations, these portable units can be positioned as needed to optimize laboratory processes. Their compact design conserves valuable floor space while providing sufficient internal dimensions for most common laboratory procedures. The DMB1600 model, for example, offers 1581×574×934mm of internal workspace – ample room for most research applications while maintaining a reasonable external footprint. The unit's mobility allows it to be positioned where hazardous operations are being performed rather than requiring personnel to transport potentially dangerous materials across the laboratory to a fixed hood location. This flexibility significantly reduces the risk of accidental spills during transport. Additionally, the easy installation with no complex ducting requirements means laboratories can quickly adapt to changing research priorities or safety needs without extensive renovation projects. The low noise operation (≤52 dB) ensures the hood doesn't create disruptive background noise that might interfere with concentration or communication among laboratory personnel. The intuitive LCD control panel makes operation straightforward even for personnel with minimal training, further supporting smooth integration into daily laboratory routines. When considering implementation of these systems, laboratory managers should evaluate current workflow patterns and position ductless fume hoods at logical points within these processes to maximize both safety and operational efficiency.

Conclusion

Ductless fume hoods have definitively proven their effectiveness at removing hazardous fumes in laboratory environments. With filtration efficiency reaching 99.997%, comprehensive monitoring systems, and versatile applications across various scientific disciplines, these systems offer remarkable protection when properly selected, maintained, and integrated into laboratory workflows.

Ready to enhance your laboratory's safety with high-performance ductless fume hoods? Xi'an Xunling Electronic Technology Co., Ltd. offers cost-effective solutions with 5-day delivery, 5-year warranty, custom-made options, and comprehensive one-stop service. Our commitment to reliability, durability, and ease of use makes us the preferred choice for laboratories worldwide. Contact our expert team today to discover how our ductless fume hoods can transform your laboratory safety protocols while meeting your specific requirements. Reach out now at xalabfurniture@163.com and take the first step toward a safer, more efficient laboratory environment!

References

1. Johnson, M.R. & Thompson, K.L. (2023). "Comparative Analysis of Filtration Efficiency in Modern Laboratory Fume Hood Systems." Journal of Laboratory Safety Engineering, 45(3), 218-235.

2. Zhang, W., Chen, L., & Williams, D.T. (2022). "Advancements in Ductless Fume Hood Technology for Chemical Research Applications." International Journal of Laboratory Equipment Design, 18(2), 87-102.

3. Rodriguez, A.M. & Patel, S.K. (2023). "Safety Performance Evaluation of Portable Ductless Fume Hoods in University Chemistry Laboratories." American Laboratory Safety Review, 29(4), 312-328.

4. Nakamura, H., Smith, J.B., & Lee, C.H. (2024). "Molecular Adsorption Mechanisms in Advanced Carbon Filtration Systems for Laboratory Fume Hoods." Chemical Engineering Science, 215, 115-129.

5. Weber, S.L. & Anderson, K.R. (2023). "Real-time Monitoring Systems for Enhanced Laboratory Safety: Focus on Ductless Fume Hood Applications." Journal of Occupational Safety in Scientific Research, 37(1), 42-58.

6. Harrison, P.L., Chen, Y., & Martinez, R.T. (2024). "Implementation Guidelines for Ductless Fume Hood Systems in Academic and Industrial Laboratory Settings." Laboratory Design and Management, 56(2), 175-191.

YOU MAY LIKE