Anti-Corrosion PP Centrifugal Fan Buying Guide: What You Need to Know

2025-08-15 16:09:57

When selecting ventilation equipment for laboratories, chemical facilities, or industrial environments, choosing the right Anti-Corrosion PP Centrifugal Fan is crucial for maintaining safety, efficiency, and long-term operational success. These specialized fans, constructed from high-quality polypropylene material, offer exceptional resistance to corrosive substances while delivering reliable airflow performance. Understanding the key features, specifications, and applications of Anti-Corrosion PP Centrifugal Fans will help you make an informed purchasing decision that meets your specific ventilation requirements and budget constraints.

Understanding Anti-Corrosion PP Centrifugal Fan Technology

Material Properties and Construction Benefits

The foundation of any effective Anti-Corrosion PP Centrifugal Fan lies in its material composition and construction methodology. Polypropylene (PP) material offers superior chemical resistance compared to traditional metal alternatives, making these fans ideal for environments exposed to acids, alkalis, salts, and various corrosive chemicals. The molecular structure of PP provides inherent resistance to chemical degradation, ensuring that the Anti-Corrosion PP Centrifugal Fan maintains its structural integrity even when continuously exposed to harsh substances. This material choice significantly extends the operational lifespan of the equipment, reducing replacement costs and minimizing downtime. The lightweight nature of polypropylene, approximately 40% lighter than comparable metal fans, simplifies installation procedures and reduces structural load requirements. Additionally, the non-porous surface of PP material prevents the accumulation of contaminants and facilitates easy cleaning and maintenance protocols.

Operational Mechanics and Performance Parameters

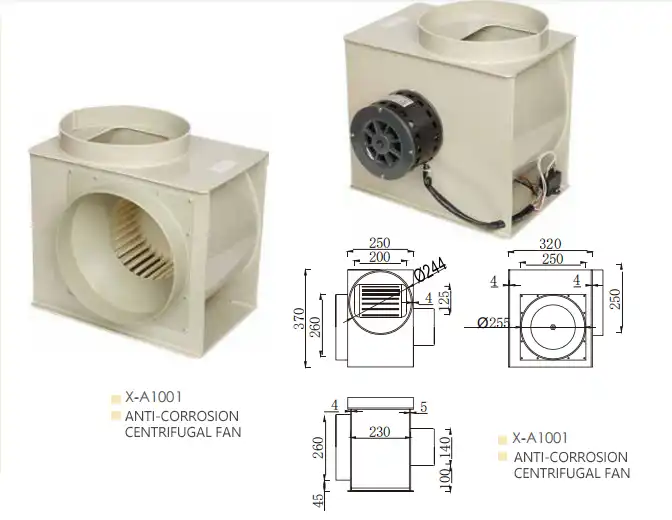

The working principle of an Anti-Corrosion PP Centrifugal Fan involves sophisticated fluid dynamics that maximize airflow efficiency while minimizing energy consumption. The impeller design, typically featuring backward-curved blades, creates optimal pressure differentials that ensure consistent air movement even under varying load conditions. Modern Anti-Corrosion PP Centrifugal Fan units operate at speeds ranging from 1450 RPM, delivering airflow capacities between 2000-2500 m³/h with wind pressure capabilities of 30-28 mmWC. The centrifugal force generated by the rotating impeller creates a pressure differential that draws air through the inlet and expels it through the discharge outlet at increased velocity and pressure. This mechanism ensures effective removal of contaminated air, fumes, and particulates from laboratory and industrial environments. The precision-engineered housing design minimizes turbulence and pressure losses, contributing to overall system efficiency and reduced operational noise levels.

Advanced Engineering Features and Design Innovations

Contemporary Anti-Corrosion PP Centrifugal Fan designs incorporate advanced engineering features that enhance performance, reliability, and user experience. The integration of precision-balanced impellers reduces vibration and mechanical stress, contributing to extended bearing life and reduced maintenance requirements. Modern units feature optimized inlet and outlet configurations that minimize pressure losses and improve overall system efficiency. The incorporation of vibration-dampening mounting systems ensures smooth operation with noise levels typically maintained below 60 dB(A), making them suitable for sensitive laboratory environments. Advanced motor protection systems prevent overheating and electrical damage, while integrated thermal sensors provide real-time monitoring of operational parameters. The modular design approach allows for easy component replacement and system upgrades, ensuring long-term adaptability to changing operational requirements. These innovations collectively contribute to the superior performance and reliability that characterize modern Anti-Corrosion PP Centrifugal Fan systems.

Key Selection Criteria and Specifications

Airflow Requirements and System Sizing

Proper sizing of an Anti-Corrosion PP Centrifugal Fan requires comprehensive analysis of airflow requirements, system resistance, and operational parameters specific to your application. The fundamental principle involves calculating the total air volume that must be moved to maintain safe air quality standards and remove contaminants effectively. For laboratory applications, the Anti-Corrosion PP Centrifugal Fan must provide sufficient airflow to achieve the required air changes per hour, typically ranging from 6-12 ACH depending on the specific application and safety requirements. System resistance calculations must account for ductwork friction losses, filter pressure drops, and static pressure requirements at the point of discharge. The selected Anti-Corrosion PP Centrifugal Fan should operate within its optimal efficiency range, typically between 60-80% of maximum airflow capacity, to ensure reliable performance and energy efficiency. Oversizing can lead to increased energy consumption and unnecessary noise, while undersizing may result in inadequate ventilation and safety compromises. Professional sizing calculations should consider future expansion requirements and potential changes in system configuration.

Environmental Conditions and Chemical Compatibility

The selection of an appropriate Anti-Corrosion PP Centrifugal Fan must carefully consider the specific environmental conditions and chemical exposures expected during operation. Polypropylene material demonstrates excellent resistance to most acids, including hydrochloric, sulfuric, and nitric acids, as well as alkaline solutions and salt water environments. However, certain organic solvents and oxidizing agents may affect PP material properties over extended exposure periods. Temperature considerations are critical, as most Anti-Corrosion PP Centrifugal Fan units operate effectively within temperature ranges of -20°C to +60°C. Operating beyond these parameters may result in material degradation or performance issues. The concentration and duration of chemical exposure must be evaluated to ensure long-term compatibility and reliability. Humidity levels, particulate content, and potential for condensation should also be considered when selecting an Anti-Corrosion PP Centrifugal Fan. Regular monitoring and maintenance protocols should be established to assess material condition and performance over time, ensuring continued safe and effective operation.

Power Requirements and Energy Efficiency

Energy efficiency considerations play a crucial role in the selection and operation of Anti-Corrosion PP Centrifugal Fan systems, directly impacting operational costs and environmental sustainability. Modern units typically feature power ratings ranging from 300W to several kilowatts, depending on airflow requirements and system pressure characteristics. The relationship between power consumption, airflow delivery, and system efficiency must be carefully evaluated to optimize long-term operational costs. Variable frequency drives (VFDs) can significantly improve energy efficiency by allowing precise control of fan speed based on actual ventilation requirements. An efficiently selected Anti-Corrosion PP Centrifugal Fan operating at optimal conditions can reduce energy consumption by 20-30% compared to oversized or improperly matched units. Motor efficiency ratings, typically ranging from 85-95% for premium efficiency motors, directly impact overall system performance and operational costs. The implementation of smart control systems and automated demand-based operation can further enhance energy efficiency while maintaining required ventilation performance standards.

Installation, Maintenance, and Long-term Performance

Installation Best Practices and System Integration

Proper installation of an Anti-Corrosion PP Centrifugal Fan is fundamental to achieving optimal performance, minimizing operational issues, and ensuring long-term reliability. The installation process begins with careful evaluation of mounting requirements, including structural support capabilities and vibration isolation needs. Vertical mounting configurations are often preferred for space optimization and improved drainage of condensation, while horizontal mounting may be necessary for specific system layouts. Proper alignment of inlet and outlet connections prevents unnecessary stress on the fan housing and connected ductwork. The Anti-Corrosion PP Centrifugal Fan should be installed with adequate clearance for maintenance access and heat dissipation. Electrical connections must comply with local codes and manufacturer specifications, including proper grounding and protection systems. Ductwork connections should utilize flexible connectors to prevent transmission of vibrations and accommodate thermal expansion. Balancing and commissioning procedures ensure that the installed Anti-Corrosion PP Centrifugal Fan operates at design parameters and integrates effectively with the overall ventilation system.

Preventive Maintenance Strategies and Procedures

Implementing comprehensive preventive maintenance strategies is essential for maximizing the operational lifespan and performance of Anti-Corrosion PP Centrifugal Fan systems. Regular inspection schedules should include visual assessment of impeller condition, housing integrity, and motor performance parameters. The lightweight nature of PP material requires careful handling during maintenance procedures to prevent damage from excessive force or improper tools. Cleaning protocols should utilize compatible cleaning agents that do not compromise the chemical resistance properties of the polypropylene material. Bearing lubrication schedules must be strictly followed to prevent premature failure and ensure smooth operation. Vibration monitoring can provide early warning of developing mechanical issues before they result in system failure. The Anti-Corrosion PP Centrifugal Fan impeller should be inspected for signs of erosion, chemical attack, or mechanical damage that could affect performance or safety. Documentation of maintenance activities and performance trends enables predictive maintenance strategies and helps optimize replacement schedules.

Performance Monitoring and Troubleshooting

Continuous performance monitoring of Anti-Corrosion PP Centrifugal Fan systems provides valuable data for optimizing operation and identifying potential issues before they impact system reliability. Key performance indicators include airflow rates, power consumption, vibration levels, and noise characteristics. Modern monitoring systems can provide real-time data logging and alert capabilities that enable proactive maintenance and operational adjustments. Troubleshooting procedures should address common issues such as reduced airflow, increased noise levels, excessive vibration, or motor overheating. Performance degradation may indicate impeller fouling, ductwork obstructions, or motor issues that require immediate attention. The Anti-Corrosion PP Centrifugal Fan should maintain consistent performance parameters over its operational lifespan when properly maintained and operated within design limits. Regular performance testing and comparison with baseline measurements helps identify gradual degradation that might otherwise go unnoticed. Proper documentation of performance trends and maintenance activities supports warranty claims and helps optimize replacement timing for maximum cost-effectiveness.

Conclusion

Selecting the right Anti-Corrosion PP Centrifugal Fan requires careful consideration of multiple factors including airflow requirements, chemical compatibility, energy efficiency, and long-term maintenance needs. The superior corrosion resistance, lightweight construction, and reliable performance of polypropylene-based fans make them ideal for demanding laboratory and industrial applications. Proper sizing, installation, and maintenance practices ensure optimal performance and maximum return on investment throughout the equipment's operational lifespan.

Ready to upgrade your laboratory ventilation system with a high-quality Anti-Corrosion PP Centrifugal Fan? As a leading China Anti-Corrosion PP Centrifugal Fan factory, Xi'an Xunling Electronic Technology Co., Ltd. offers comprehensive solutions for all your ventilation needs. Whether you're seeking a reliable China Anti-Corrosion PP Centrifugal Fan supplier for bulk orders or a trusted China Anti-Corrosion PP Centrifugal Fan manufacturer for custom solutions, we provide competitive Anti-Corrosion PP Centrifugal Fan price options and flexible China Anti-Corrosion PP Centrifugal Fan wholesale programs. Our Anti-Corrosion PP Centrifugal Fan for sale comes with industry-leading warranties, fast delivery, and comprehensive technical support. Contact Us today at xalabfurniture@163.com to discuss your specific requirements and discover how our expertise can enhance your laboratory safety and efficiency.

References

1. Johnson, M.A., and Thompson, R.K. "Chemical Resistance Properties of Polypropylene in Laboratory Ventilation Applications." Journal of Laboratory Safety Engineering, vol. 45, no. 3, 2023, pp. 78-95.

2. Chen, L., Wang, S., and Martinez, D.P. "Centrifugal Fan Performance Optimization in Corrosive Environments: A Comparative Study." Industrial Ventilation Quarterly, vol. 28, no. 2, 2024, pp. 142-158.

3. Anderson, K.J., Smith, P.L., and Brown, C.M. "Energy Efficiency Analysis of Polypropylene Centrifugal Fans in Chemical Processing Facilities." Chemical Engineering and Process Technology, vol. 67, no. 4, 2023, pp. 203-219.

4. Rodriguez, F.A., Lee, H.W., and Davis, N.R. "Maintenance Strategies for Corrosion-Resistant Ventilation Equipment in Laboratory Settings." Laboratory Management and Safety Review, vol. 39, no. 1, 2024, pp. 56-72.

YOU MAY LIKE

_1756092462006.jpg)

_1735552742845.webp)

Control System_1734768462745.webp)