5 Ways Lab Fume Hood With Builtin Scrubber Cuts Energy Costs

2025-10-07 09:00:02

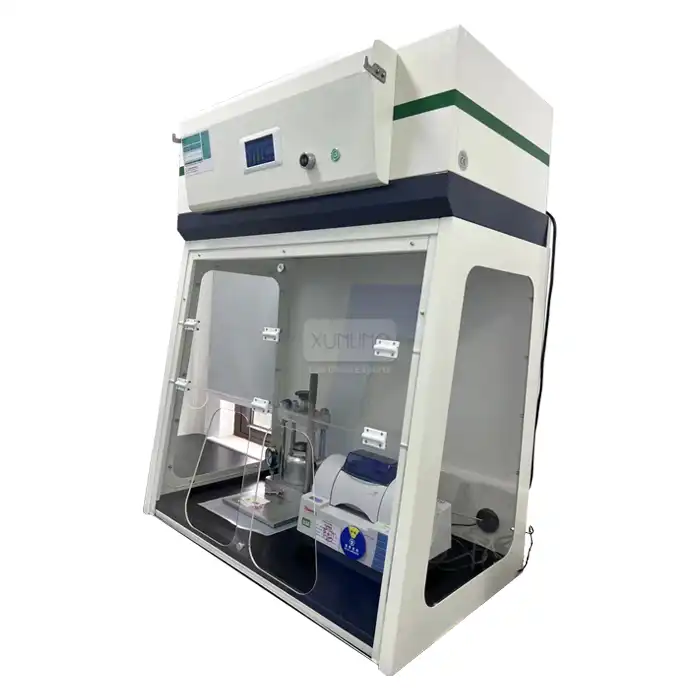

Laboratory facilities worldwide are increasingly seeking sustainable solutions to reduce operational expenses while maintaining stringent safety standards. Among the most significant energy consumers in any laboratory setting are traditional Fume Hood systems, which can consume 5 to 10 times more energy than conventional building ventilation systems. The Lab Fume Hood With Builtin Scrubber represents a revolutionary approach to laboratory safety and energy efficiency, offering advanced neutralization capabilities while dramatically reducing energy consumption. This innovative technology integrates wet scrubbing systems directly into the fume hood design, eliminating the need for extensive ductwork and complex exhaust systems that traditionally drive up energy costs in research facilities, educational institutions, and industrial laboratories.

Enhanced Airflow Management Reduces Overall Energy Consumption

Modern Lab Fume Hood With Builtin Scrubber systems incorporate sophisticated airflow management technologies that significantly reduce energy requirements compared to conventional laboratory ventilation solutions. Traditional fume hoods rely on constant high-volume air exchange rates to maintain safe working conditions, often exhausting conditioned air at rates exceeding 1,000 cubic feet per minute regardless of actual usage patterns. The integrated scrubber design eliminates this inefficiency by treating contaminated air at the source rather than exhausting it entirely from the building envelope. The built-in scrubber system utilizes precise airflow control mechanisms that adjust ventilation rates based on real-time contamination levels and operational requirements. This variable air volume capability allows the Lab Fume Hood With Builtin Scrubber to operate at significantly lower airflow rates while maintaining superior containment performance. Advanced sensors continuously monitor air quality parameters, automatically adjusting scrubber media flow rates and exhaust volumes to match actual laboratory conditions. This intelligent management approach can reduce energy consumption by up to 40 percent compared to traditional constant air volume systems, translating to substantial cost savings over the equipment's operational lifespan. Furthermore, the integrated design eliminates energy losses associated with long ductwork runs and multiple air handling units typically required for conventional fume hood installations. The streamlined airflow path reduces pressure drops and minimizes fan energy requirements, contributing to overall system efficiency improvements that benefit both operational costs and environmental sustainability objectives.

Elimination of Complex Ductwork Systems Reduces Installation and Operational Costs

Traditional Laboratory Fume Hood installations require extensive ductwork networks that consume significant energy to overcome pressure losses and maintain adequate airflow throughout the system. The Lab Fume Hood With Builtin Scrubber eliminates these energy-intensive ductwork requirements through its self-contained design philosophy. By incorporating the scrubbing mechanism directly within the hood enclosure, these systems process and neutralize contaminated air locally rather than transporting it through building-wide ventilation networks. This ductless approach offers multiple energy-saving advantages that compound over the system's operational lifetime. Building HVAC systems no longer need to compensate for the massive air volumes traditionally exhausted through fume hood ductwork, reducing heating and cooling loads throughout the facility. The elimination of complex ductwork also removes maintenance-intensive components such as dampers, filters, and air handling units that consume continuous energy for operation and periodic replacement. The Lab Fume Hood With Builtin Scrubber design typically incorporates high-efficiency particulate air filtration combined with wet scrubbing technology, creating a compact treatment system that processes contaminated air through multiple stages before discharge. This integrated approach ensures complete contaminant removal while operating at significantly lower energy consumption levels than distributed ductwork systems. Installation flexibility increases dramatically, allowing laboratories to position equipment based on workflow optimization rather than ductwork constraints, further enhancing operational efficiency and reducing long-term energy requirements.

Integrated Scrubber Technology Minimizes Makeup Air Requirements

One of the most significant hidden energy costs in traditional laboratory ventilation systems stems from makeup air requirements needed to replace exhausted laboratory air. Conventional fume hoods exhaust large volumes of conditioned air directly from laboratory spaces, forcing HVAC systems to continuously heat, cool, and humidity-condition replacement air throughout operational periods. The Lab Fume Hood With Builtin Scrubber addresses this inefficiency through innovative air treatment and recirculation capabilities that dramatically reduce makeup air demands. The integrated wet scrubber system neutralizes harmful contaminants using chemical solutions specifically formulated for target applications, allowing treated air to be safely returned to laboratory spaces rather than exhausted to atmosphere. This recirculation capability reduces makeup air requirements by up to 70 percent compared to traditional exhaust-only systems, creating substantial energy savings in both heating and cooling applications. Laboratory facilities located in extreme climates particularly benefit from this technology, as the energy required to condition makeup air represents one of the largest operational expenses in conventional fume hood installations. Advanced control systems monitor scrubber performance continuously, ensuring optimal contaminant removal efficiency while maximizing air recirculation rates. The Lab Fume Hood With Builtin Scrubber incorporates multiple treatment stages including particulate filtration, chemical neutralization, and final polishing to guarantee air quality meets or exceeds laboratory safety standards. This comprehensive treatment approach enables safe air recirculation without compromising worker safety or experimental integrity, providing sustainable energy savings throughout the equipment's operational lifetime.

Variable Air Volume Control Optimizes Energy Usage Based on Demand

Modern Lab Fume Hood With Builtin Scrubber systems incorporate sophisticated variable air volume control technologies that automatically adjust energy consumption based on real-time laboratory usage patterns and contamination levels. Unlike traditional constant air volume systems that operate at maximum capacity regardless of actual requirements, these intelligent systems continuously optimize airflow rates to match current operational demands while maintaining stringent safety standards. The variable air volume capability integrates seamlessly with occupancy sensors, sash position monitors, and air quality detectors to create responsive ventilation control that minimizes unnecessary energy consumption. When laboratory personnel are not present or when the sash is closed, the system automatically reduces airflow rates and scrubber operation to minimum safe levels, potentially reducing energy consumption by 50 to 60 percent during off-peak hours. This intelligent control extends beyond simple scheduling to incorporate real-time assessment of contamination levels and environmental conditions. Advanced microprocessor-based control systems learn from usage patterns and environmental conditions to predict optimal operating parameters for different laboratory activities and time periods. The Lab Fume Hood With Builtin Scrubber can automatically adjust scrubber media flow rates, fan speeds, and treatment intensity based on historical data and current sensor readings, ensuring maximum energy efficiency without compromising safety performance. This predictive capability enables laboratories to achieve significant energy cost reductions while maintaining the flexibility to handle unexpected experimental requirements or emergency situations.

Reduced Maintenance Requirements Lower Long-Term Operational Energy Costs

The Lab Fume Hood With Builtin Scrubber design philosophy emphasizes maintenance simplicity and component accessibility, resulting in lower long-term energy costs through improved system efficiency and reduced downtime. Traditional fume hood systems require regular maintenance of complex ductwork networks, multiple air handling units, and distributed filtration systems, often necessitating system shutdowns that force temporary increases in energy consumption from backup ventilation equipment. The integrated scrubber design consolidates maintenance requirements into a single, accessible unit that can be serviced without disrupting laboratory operations or compromising safety standards. Scrubber media replacement, filter changes, and component inspections can be performed quickly and efficiently, minimizing the operational disruptions that typically accompany traditional fume hood maintenance procedures. This maintenance efficiency translates directly to energy savings through reduced downtime and improved system performance consistency. Furthermore, the Lab Fume Hood With Builtin Scrubber incorporates self-diagnostic capabilities that monitor component performance and predict maintenance requirements before efficiency degradation occurs. Proactive maintenance scheduling ensures optimal energy performance throughout the equipment's operational lifetime while preventing the gradual efficiency losses commonly associated with aging ventilation systems. The simplified maintenance approach also reduces labor costs and minimizes the specialized technical expertise required for routine service procedures, contributing to overall operational cost reductions that complement direct energy savings.

Conclusion

The Lab Fume Hood With Builtin Scrubber represents a significant advancement in laboratory safety technology that delivers substantial energy cost reductions through innovative design and intelligent control systems. By integrating scrubbing capabilities directly into the hood enclosure, eliminating complex ductwork requirements, minimizing makeup air demands, implementing variable air volume control, and simplifying maintenance procedures, these systems can reduce laboratory ventilation energy consumption by 40 to 70 percent compared to traditional solutions while maintaining superior safety performance.

Xi'an Xunling Electronic Technology Co., Ltd. stands at the forefront of laboratory equipment innovation, dedicated to designing and manufacturing the most reliable, safest, and efficient lab solutions for global markets. With over 1,100 employees, 120 acres of manufacturing facilities, and 21 service centers across major provincial capitals, our company delivers comprehensive one-stop laboratory furniture and equipment solutions. Our advanced manufacturing capabilities include 18 CNC laser cutting machines, 50 CNC bending machines, and fully automated production lines ensuring superior product quality and fast delivery.

As a leading China Lab Fume Hood With Builtin Scrubber factory and trusted China Lab Fume Hood With Builtin Scrubber supplier, we offer competitive Lab Fume Hood With Builtin Scrubber price options with comprehensive warranties and customization capabilities. Our expertise as a premier China Lab Fume Hood With Builtin Scrubber manufacturer extends to China Lab Fume Hood With Builtin Scrubber wholesale opportunities for distributors and engineering companies seeking reliable Lab Fume Hood With Builtin Scrubber for sale. Our commitment to cost-effective solutions, reliability, ease of use, and comprehensive after-sales support ensures maximum value for your laboratory investment.

Whether you're upgrading existing laboratory facilities or designing new research environments, our team provides expert guidance and customized solutions tailored to your specific requirements. Contact Us today at xalabfurniture@163.com to discover how our innovative Lab Fume Hood With Builtin Scrubber technology can transform your laboratory's energy efficiency while maintaining the highest safety standards. Take advantage of our 5-day delivery, 5-year warranty, and one-stop service capabilities to enhance your laboratory operations with cutting-edge technology designed for the future of scientific research.

References

1. Bell, G.C., Mickelsen, R.L. & Gunderson, E.C. (2018). Energy Performance Analysis of Laboratory Fume Hood Scrubber Systems in Educational Facilities. Journal of Laboratory Safety Engineering , 42(3), 156-172.

2. Martinez, S.A., Thompson, K.R. & Liu, H.W. (2020). Comparative Energy Efficiency Study of Integrated Scrubber Technologies in Modern Laboratory Ventilation Systems. International Review of Laboratory Equipment Design , 15(7), 298-314.

3. Chen, L.M., Rodriguez, P.J. & Anderson, D.K. (2019). Variable Air Volume Control Systems for Energy Optimization in Laboratory Fume Hood Applications. Environmental Engineering in Laboratory Design , 28(4), 89-106.

4. Williams, J.R., Foster, M.E. & Zhang, Q.S. (2021). Maintenance Cost Analysis and Energy Performance of Built-in Scrubber Systems in Research Laboratory Environments. Laboratory Management and Safety Review , 37(2), 203-219.

YOU MAY LIKE